Near-zero-emission treatment system and technology for ternary precursor material production wastewater

A near-zero emission and treatment system technology, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve problems such as high operating cost, long treatment process, and large environmental impact, and achieve heat balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

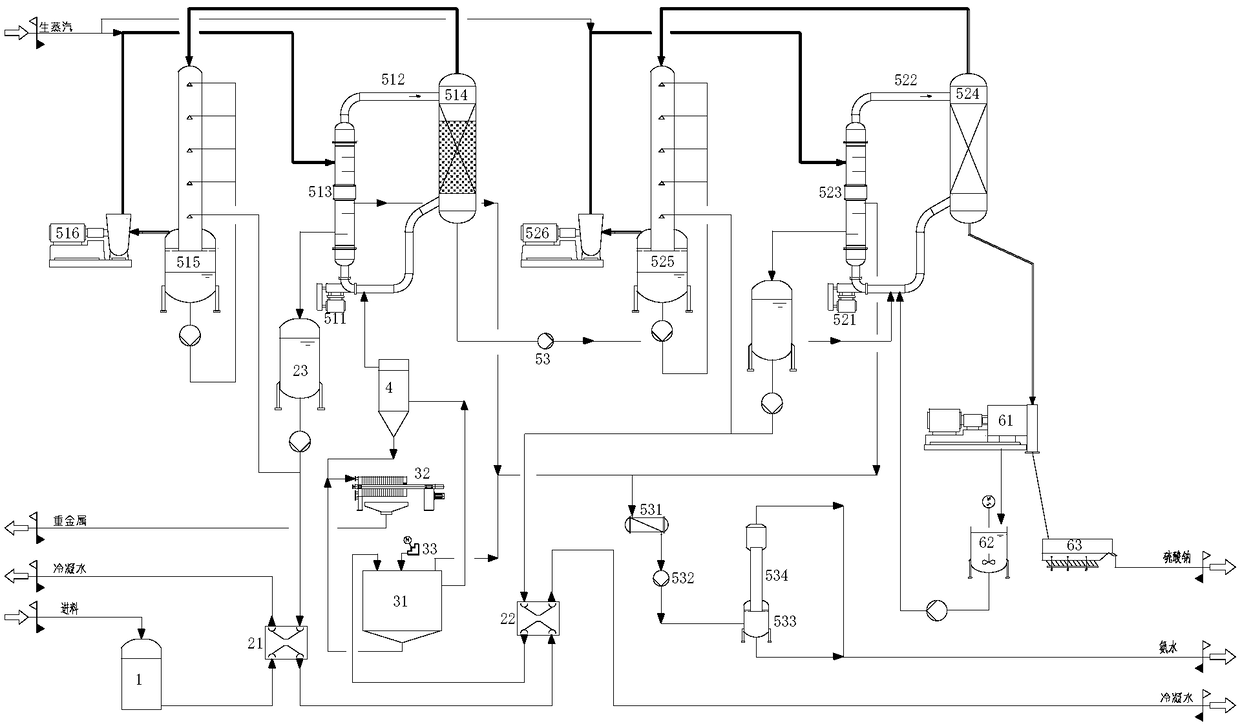

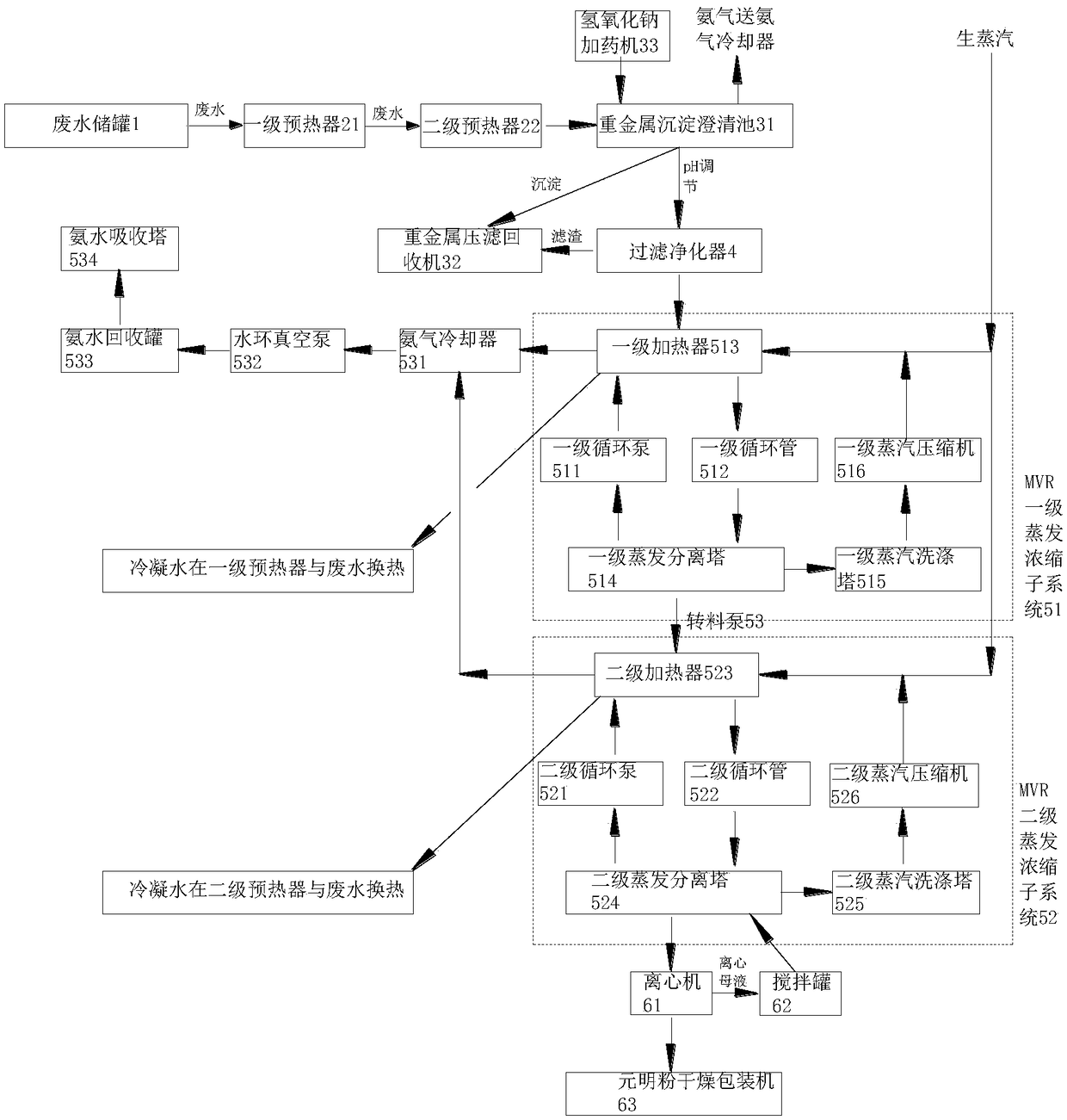

[0041] The near-zero discharge treatment system of the ternary precursor material production wastewater in this embodiment is as follows: figure 1 shown, including:

[0042] Wastewater storage tank 1, used to store ternary precursor mother liquor wastewater (washing concentrated water is merged into mother liquor wastewater);

[0043] The preheater includes a primary preheater 21 and a secondary preheater 22. The primary preheater 21 and the secondary preheater 22 are sequentially connected after the waste water storage tank 1, and the waste water flowing through the preheater 2 is processed. Heating to raise the temperature; wherein the primary preheater 21 and the secondary preheater 22 are heat transfer heat exchangers, and the hot water ends of the primary preheater 21 and the secondary preheater 22 are respectively connected to a condensed water storage Tank 23, two condensed water storage tanks 23 are respectively connected with the heaters in the MVR primary evaporatio...

Embodiment 2

[0053] A ternary precursor material factory 2m 3 / h Near-zero discharge treatment process of ternary precursor wastewater.

[0054] Table 1 Raw water quality data

[0055] main ingredient

Kg / h

mg / L

Remark

Ni

0.9

450

co

0.3

150

mn

0.28

140

NH 4+

14.4

7200

NH 3 Convert to NH 4+

Na 2 SO 4

236

118000

Density ρ

1020Kg / m 3

Flow Q

2m 3 / h

pH

10-12

temperature

30℃

[0056] 1) The wastewater from the production of the ternary precursor is sent to the primary preheater 21 and the secondary preheater 22, and the temperature rises to 85°C after preheating;

[0057] 2) Send the twice preheated waste water into the sealed heavy metal sedimentation and clarification tank 31, add sodium hydroxide solution to the waste water, control the pH of the waste water>12, and decomplex the heavy metal comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com