Industrial plant heating and dustless and volatile organic chemicals (VOCs) near zero emission process

An industrial plant, near-zero emission technology, applied in the direction of chemical instruments and methods, the use of liquid separation agent, the separation of dispersed particles, etc., can solve the problems of environmental pollution, increase the production cost of enterprises, and the quality impact of spraying, etc., to achieve strong economy Feasibility, reduction of total emissions, and reduction of production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

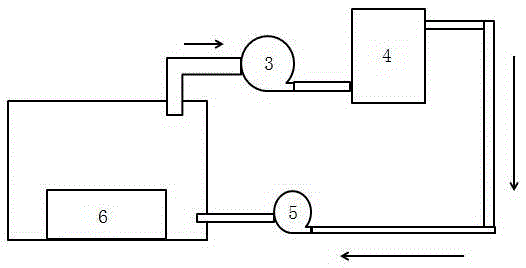

[0027] Such as figure 1 The shown process for temperature supplementation, dust-freeization and VOCs near-zero emission of an industrial plant mainly includes the following steps:

[0028] (1) Use the fan 3 to collect the volatile organic waste gas (VOCs) in the industrial plant, and collect the waste gas;

[0029] (2) Transport the waste gas collected in step (1) to the waste gas treatment integrated system 4 for the treatment of volatile organic waste gas VOCs. Specifically, the waste gas is first sprayed and absorbed by water or surfactants, and then passed through Fe- C material for adsorption, and finally catalyzed by Fe-C material and oxidant for catalytic oxidation treatment; the oxidant is hydrogen peroxide or calcium hypochlorite or a mixture of the two; the volatile organic waste gas treated in step (2) is finally converted Small molecule, non-toxic and harmless CO 2 and H 2 O;

[0030] (3) The gas treated in step (2) is input into the factory building through t...

Embodiment 2

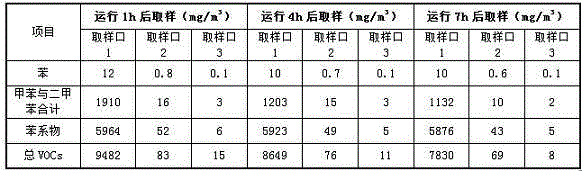

[0031] Embodiment 2 pilot test

[0032] In order to further verify the feasibility of the patented technology, a pilot test was carried out in the pilot laboratory of Nanjing Glote Environmental Engineering Co., Ltd.

[0033] Experimental program:

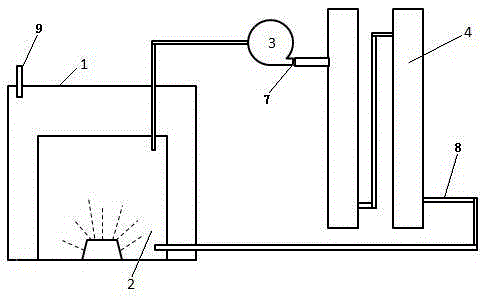

[0034] Such as figure 2As shown, in the experiment, a spraying container 2 with a size of 1m*1m*1m was used to simulate the factory building. The container 2 was made of plastic pp material, and the paint was atomized by a pump and an atomizing device in the container 2, forming a large amount of volatile organic waste gas The fan 3 is connected outside the container, the outlet of the fan 3 is connected with the waste gas treatment integrated system 4 , and the waste gas outlet of the waste gas treatment integrated system 4 is connected with the container 2 through the return fan 5 . The outside of the container 2 is wrapped by an outer shell packing box 1 of 1.5m*1.5m*1.5m. The details of the device are as figure 2 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com