Method for disposal of solid waste by ceramsite kiln and ceramsite kiln for disposal of solid waste

A technology of solid waste and ceramsite, applied in the field of ceramsite kiln, can solve the problems of hidden pollution and cost, and achieve the effect of near-zero emission reduction, overcoming high cost and widening the usable range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

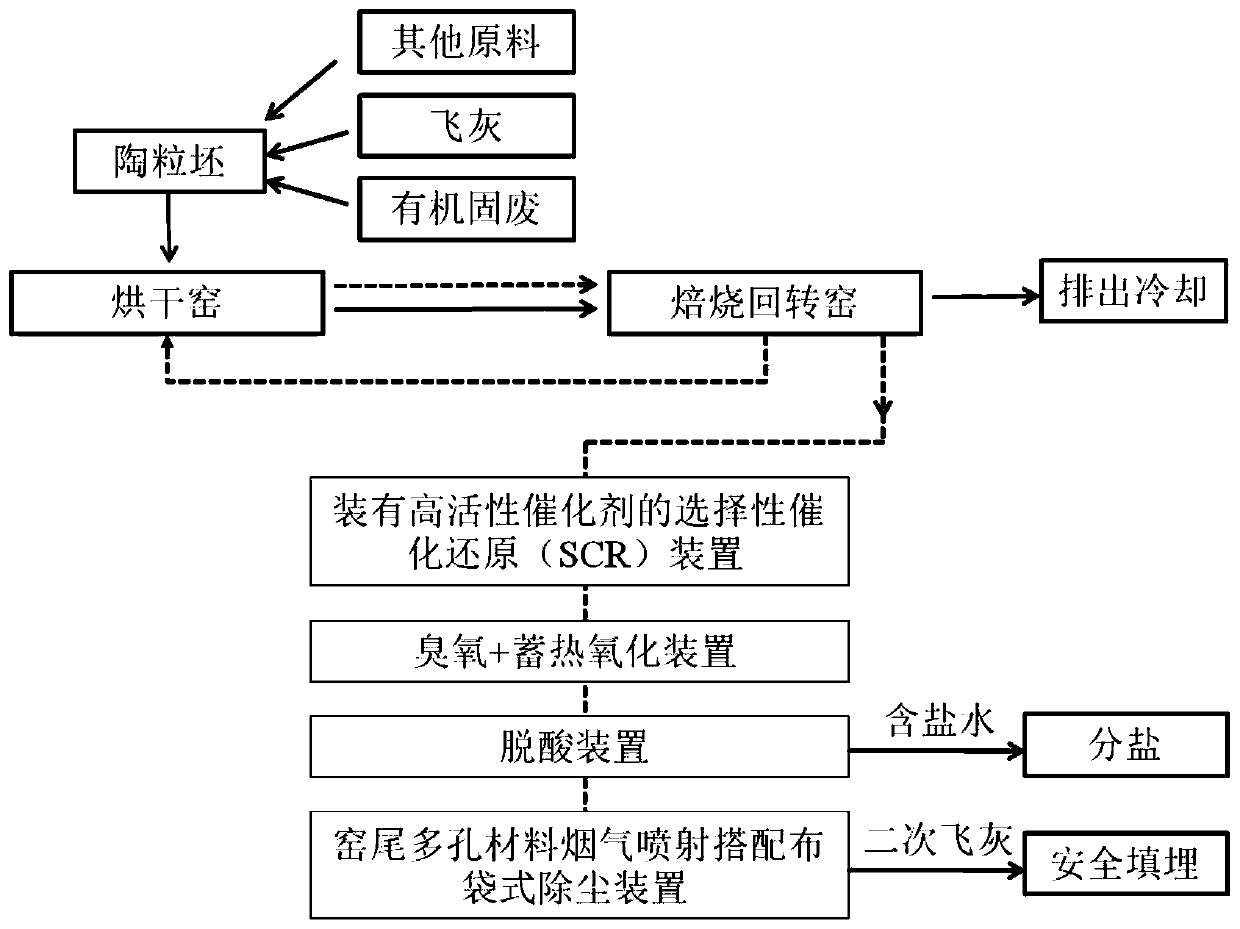

Method used

Image

Examples

Embodiment 1

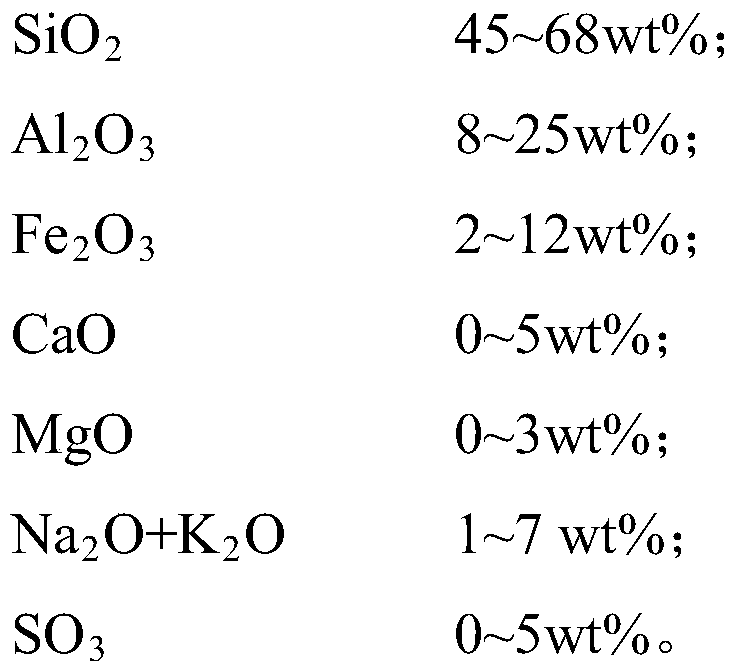

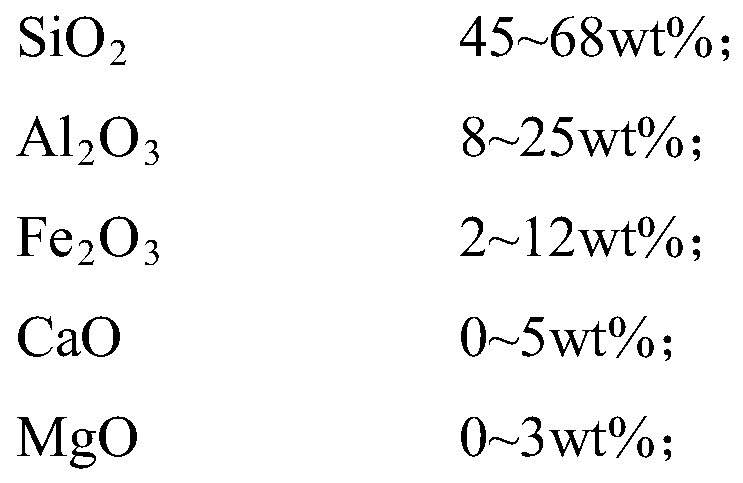

[0079] 60% of shale, 30% of waste incineration fly ash, and 10% of auxiliary raw materials are pre-crushed and sent to the small silo respectively. A spiral metering device is installed under the silo, and the parameters of SiO are prepared according to the ceramsite raw material. 2 53wt%, Al 2 o 3 20wt%, Fe 2 o 3 5wt%, CaO 3wt%, MgO 1wt%, Na 2 O+K 2 O 2wt%, SO 3 0.5% for batching parameters to measure the amount of material, and then uniformly transported to the ceramsite raw material mixing ball mill device, through the impact, extrusion and grinding of the ball milling medium, the material is fully mixed and the passing rate of the square hole sieve with a fineness of 0.045mm is greater than 95%, then the mixed material falls from the outlet of the ball mill to the conveyor belt, and is sent to the ceramsite granulation device. In the ceramsite billet granulation device, the mixed material is mixed with the water at the outlet of the spray device to form a mixed m...

Embodiment 2

[0082] With embodiment 1, wherein change point is that ceramsite raw material preparation parameter is SiO 2 46wt%, Al 2 o 3 25wt%, Fe 2 o 3 5wt%, CaO 3wt%, MgO 1.5wt%, Na 2 O+K 2O 4wt%, SO 3 2.5%; the catalyst in the SCR device is V loaded with precious metal Pd 2 o 5 -WO 3 / TiO 2 ; The porous material for flue gas injection at the kiln tail is porous γ-Al 2 o 3 ; Deacidification unit contains 15wt% Ca(OH) 2 solution.

[0083] After testing, the performance indicators of ceramsite are as follows:

[0084] The results of ceramsite heavy metal leaching value (unit mg / L) are, Cu 0.009, Ni 0.006, As 0.008, Pb 0.004, Cr 0.002, Ge 0.0007, Hg content is lower than the instrument detection limit; Dioxin content (0.016ngI-TEQ / Nm 3 ), meeting the secondary standard requirements of GB16889-2008 "Pollution Control Standards for Domestic Garbage Landfill Sites" and GB15618-2008 "Soil Environmental Quality Standards" (draft for comments). The physical properties of cer...

Embodiment 3

[0086] With embodiment 1, wherein change point is that ceramsite raw material preparation parameter is SiO 2 62wt%, Al 2 o 3 16wt%, Fe 2 o 3 8wt%, CaO 2wt%, MgO 1.5wt%, Na 2 O+K 2 O 3wt%, SO 3 1.5%; the catalyst in the SCR device is V loaded with bimetallic complexes 2 o 5 -WO 3 / TiO 2 ; The porous material for kiln tail flue gas injection is active boron nitride; the deacidification device contains 20wt% Mg(OH) 2 solution.

[0087] After testing, the performance indicators of ceramsite are as follows: ceramsite heavy metal leaching value (unit mg / L) results are, Cu 0.005, Ni 0.001, As 0.008, Pb 0.001, Cr 0.001, Ge 0.0005, Hg content is lower than the detection limit of the instrument ; Dioxin content (0.012ng I-TEQ / Nm 3 ), meeting the secondary standard requirements of GB16889-2008 "Pollution Control Standards for Domestic Garbage Landfill Sites" and GB15618-2008 "Soil Environmental Quality Standards" (draft for comments). The physical properties of ceramsite a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com