Deep treatment system and process for paper-making wastewater

A technology for advanced treatment and papermaking wastewater, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply conservation, etc., can solve the problems of increased corrosion, low efficiency of wastewater treatment, incomplete sterilization, etc. problems, to achieve the effect of less corrosion to equipment, improve the quality of produced water, and poor disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

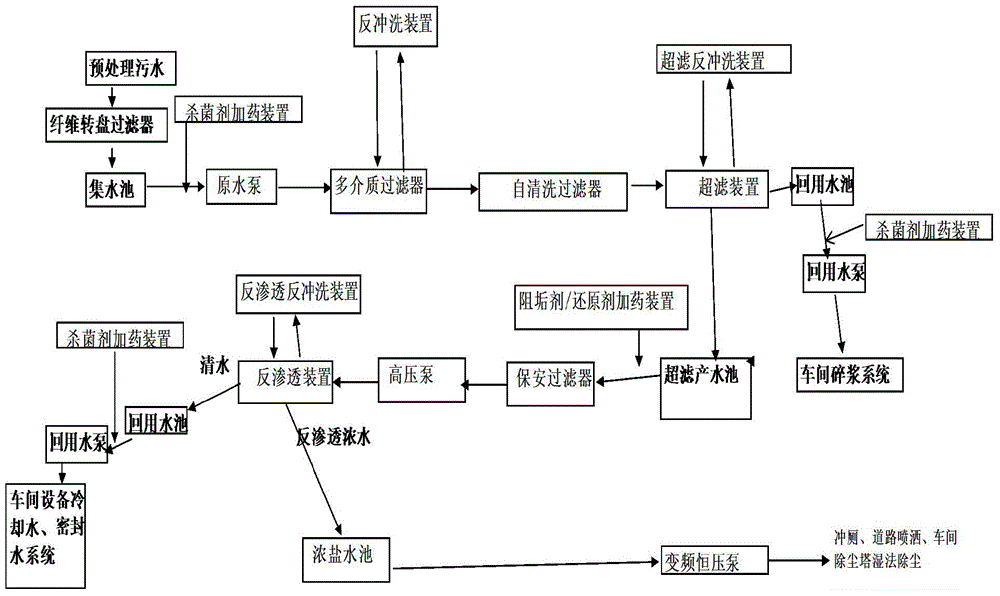

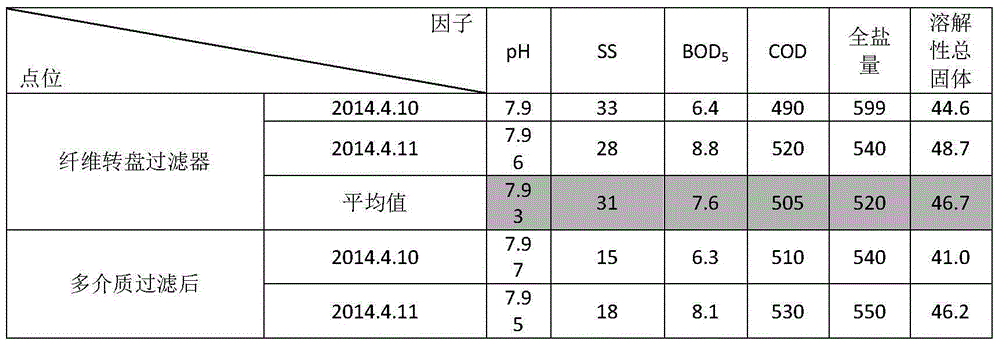

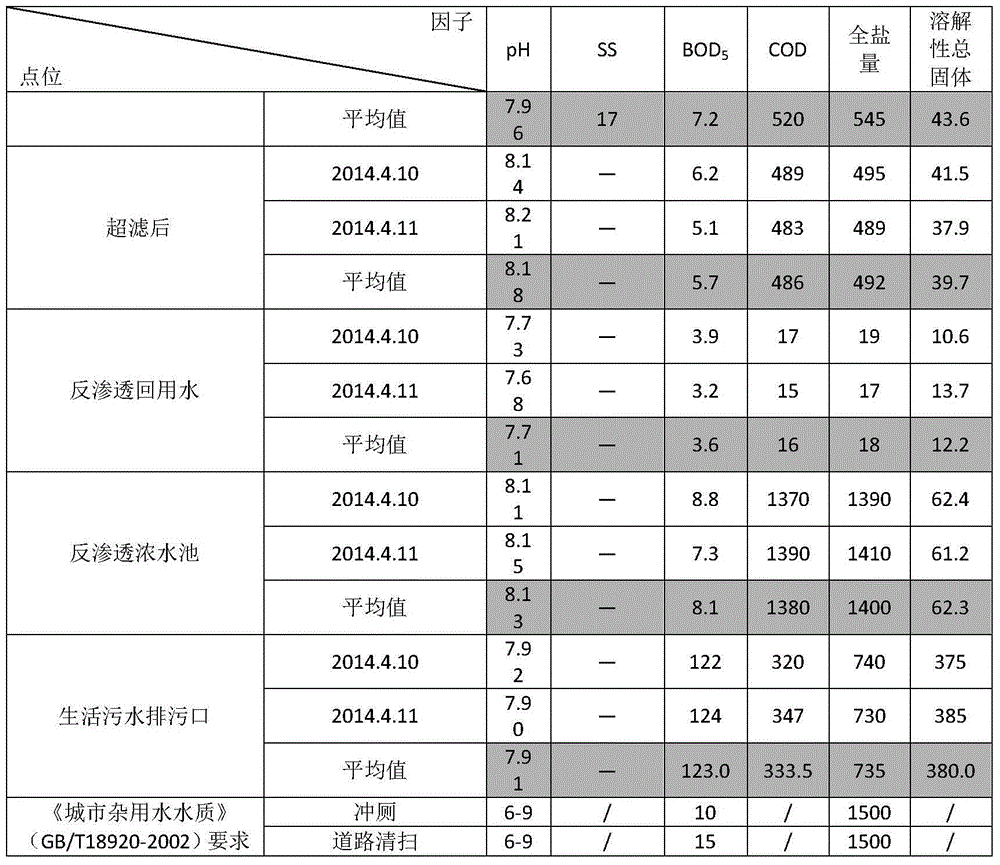

[0034] refer to figure 1 As shown, the papermaking wastewater advanced treatment system of the present invention belongs to the improvement carried out by Shandong Hengan Paper Industry Co., Ltd. on the basis of the original wastewater treatment. Installed fiber rotary disc filter, sump, raw water pump, multi-media filter, self-cleaning filter, ultrafiltration device, ultrafiltration water production tank, security filter, high pressure pump, reverse osmosis device, concentrated brine tank, each device passes through The other end of the ultrafiltration device is also connected to the reuse water pool, and the clean water produced by ultrafiltration is pumped into the pulping system of the workshop through the reuse water pump; the other end of the reverse osmosis device is also connected to the reuse water pool. The reuse water pump pumps the clean water produced by reverse osmosis into the cooling water and sealing water system of the workshop equipment; it also includes a f...

Embodiment 2

[0054] A papermaking wastewater advanced treatment process, the specific process is as follows:

[0055] (1) The water from the three sedimentation tanks of the sewage treatment station is pre-filtered through the rotary filter, and then pressurized by the raw water pump into the multi-media filter, and filtered through the quartz sand and anthracite filter material in the multi-media filter to remove Turbidity, large suspended solids, the filter water is then filtered through the self-cleaning filter for large suspended solids, impurities and some colloids in the water; during the filtration process of the multimedia filter, when one of the filters is under the Reach 0.8-1.0kg / cm 2 Or when the SDI of the effluent is greater than 3, it will automatically exit for backwashing, using the mixed backwashing method of first air washing and then water washing, backwashing intensity: water washing 10-13L / M 2 ·S, air wash 10-20L / M 2 S, reverse osmosis concentrated water is used for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com