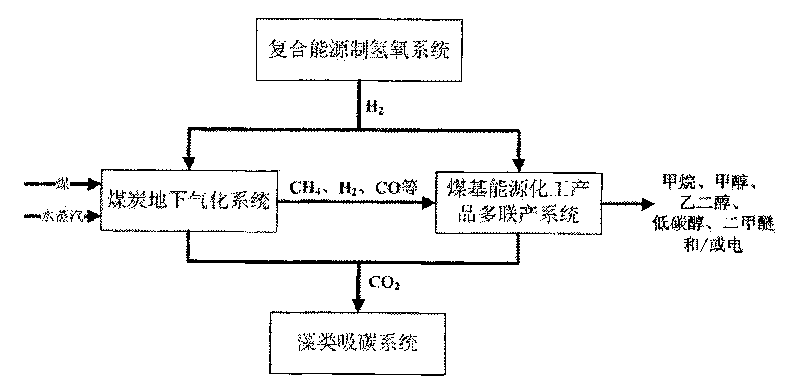

Underground gasification coal derived energy chemical product poly-generation system and method

A technology for underground gasification and chemical products, applied in fuel system, petroleum industry, energy input, etc., can solve problems such as high cost and inability to reduce carbon dioxide, and achieve the effects of low cost, reduced production cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

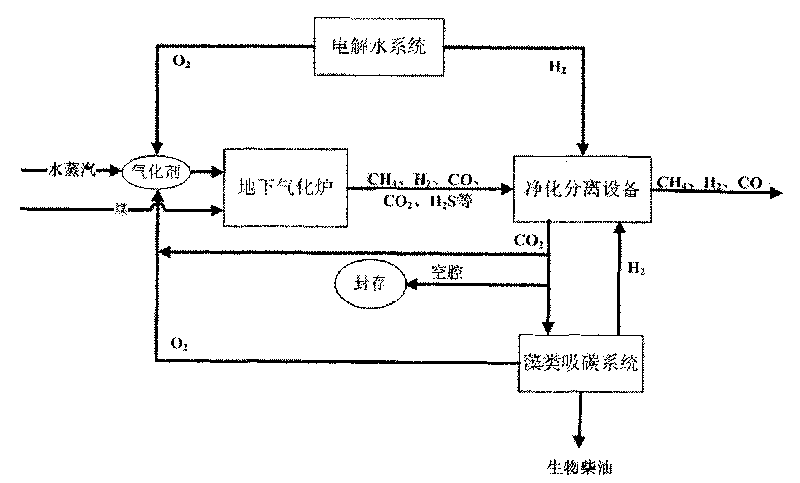

[0043] like image 3 As shown in the figure, the oxygen generated by electrolyzed water or algae carbon absorption matches the steam generated by the steam boiler, and is injected into the gasification channel of the underground gasifier in a certain proportion to contact the coal seam for oxidation, reduction, drying and retorting reactions, and generate carbon monoxide, carbon monoxide, Raw gas of hydrogen, carbon dioxide, methane, hydrogen sulfide and other gases. The production of combustible gas passes through three reaction zones in the gasification channel: oxidation zone, reduction zone and dry distillation zone. In the oxidation area, the oxygen in the gasification agent and the carbon in the coal seam undergo a heterogeneous chemical reaction, which generates a large amount of heat and makes the coal seam hot, and its temperature ranges from 900 to 1450 °C. Because in the gasification channel, oxygen contacts with coal, reacts quickly and is consumed. As long as th...

Embodiment 2

[0045] like Figure 4 As shown, the oxygen and water vapor generated by electrolysis of water or algae carbon absorption go through the first-stage oxygenation and oxidation exothermic reaction in the underground coal gasification, and then the hydrogen is injected into the underground coal gasification process to directly react with the coal char to generate a large amount of methane. And a small amount of hydrogen, carbon monoxide, carbon dioxide, oxygen and other gases, purified to obtain methane. The injected hydrogen can be partly derived from a small amount of hydrogen obtained from the gasification and separation of the first-stage oxygenated oxidation reaction output, and the insufficient part can be supplied by the electrolysis water system or algae photosynthesis. The carbon dioxide in the gasifier can be directly sent to the algae carbon absorption process for the production of biodiesel, or it can be stored in the cavity produced by the underground gasification, an...

Embodiment 3

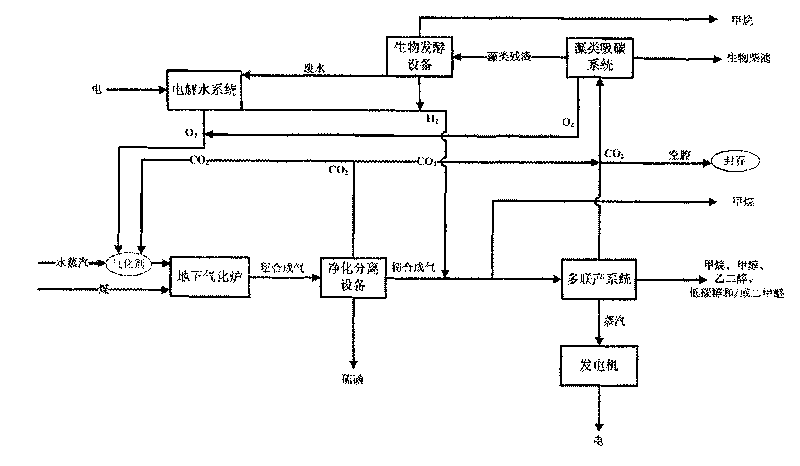

[0047] like Figure 5 As shown, the purified syngas obtained by underground coal gasification has the components of methane, hydrogen and carbon monoxide after purification. After the refined synthesis gas is separated from methane, the remaining hydrogen and carbon monoxide can be directly methanated to prepare methane, and can also be sent to a multi-generation system to synthesize methanol, and the methanol can be further dehydrated to prepare dimethyl ether. The hydrogen-to-carbon ratio required for methanation or methanol synthesis can be adjusted by electrolysis of water and / or hydrogen produced by fermentation of algal residues produced by the algal carbon absorption system. In the multi-generation system, the slack gas generated after methanol synthesis can be used as gas for power generation, and part of the high-temperature steam generated in the underground gasification section can be used to drive the steam turbine to generate power. In addition, the methane synth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com