Organic solid rubbish combustion integration device and method

A technology for organic solids and incineration devices, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of complexity and high maintenance costs, achieve the effects of reasonable structure, easy maintenance, and improved energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

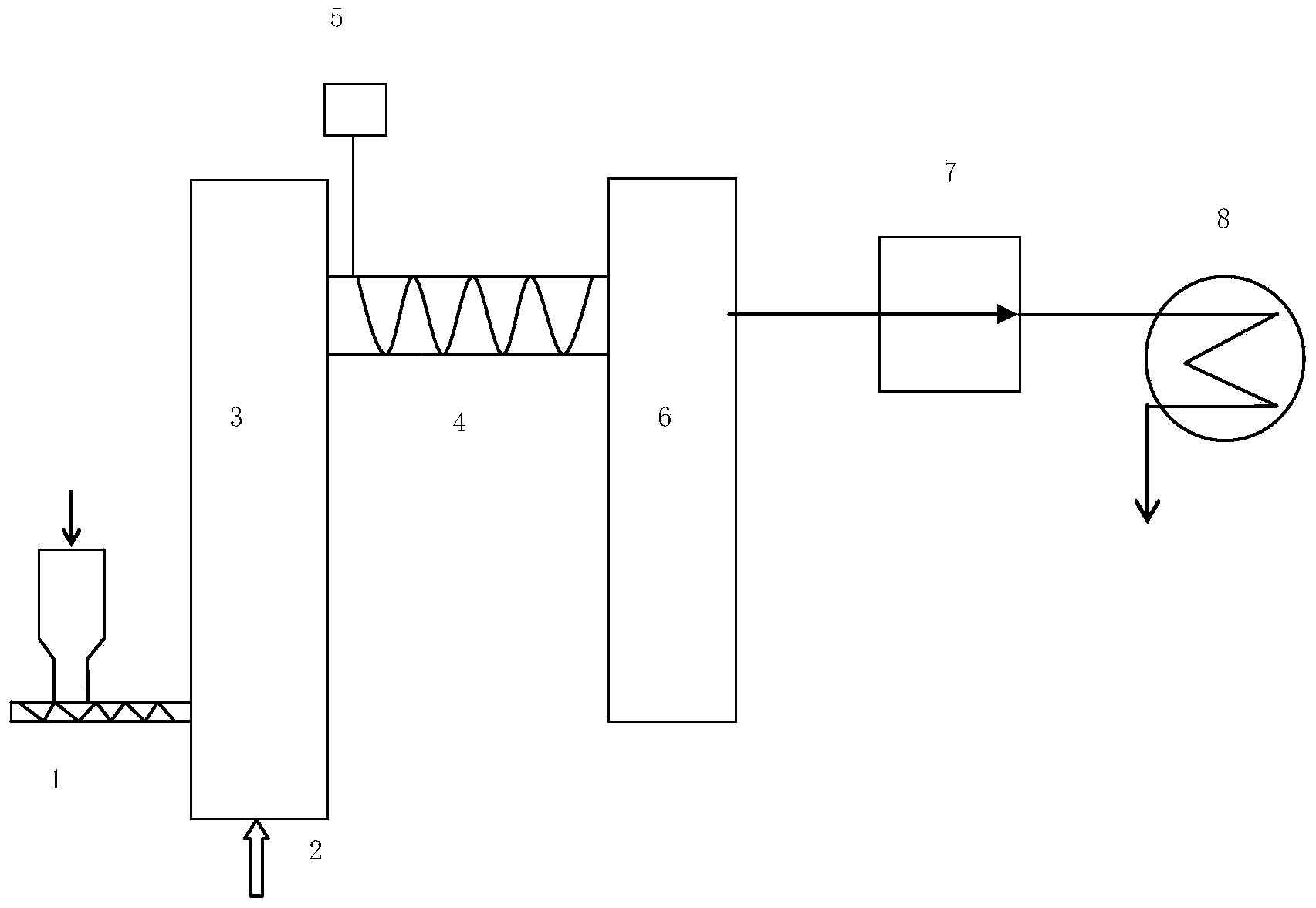

[0013] An integrated organic solid waste incineration device and method is composed of an incineration device 3 , a convertible heat exchanger 4 , an area regulator 5 , a high-temperature dust removal device 6 , a waste heat boiler 7 and a power generation device 8 . The organic solid waste is fed into the incineration device 3 through the feeder 1, and at the same time, the bottom of the incineration device 3 is fed with a combustion aid such as air, oxygen or a mixture of the two, and the organic solid waste is in contact with the combustion aid at the bottom of the incineration device 3 Combustion starts, and the high-temperature flue gas produced after full combustion is discharged from the upper outlet of the incinerator 3 into the convertible heat exchanger 4, which is controlled by the area regulator 5 to adjust the high-temperature flue gas and the convertible heat exchanger 4 heat exchange area, and then control the temperature of the flue gas entering the high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com