Method for preparing flocculant liquid polyaluminum chloride from aluminum ash

A technology of polyaluminum chloride and flocculant, applied in aluminum chloride, aluminum halide, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of environmental pollution, direct or indirect harm to the environment, and avoid secondary pollution , The effect of making full use of renewable resources and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

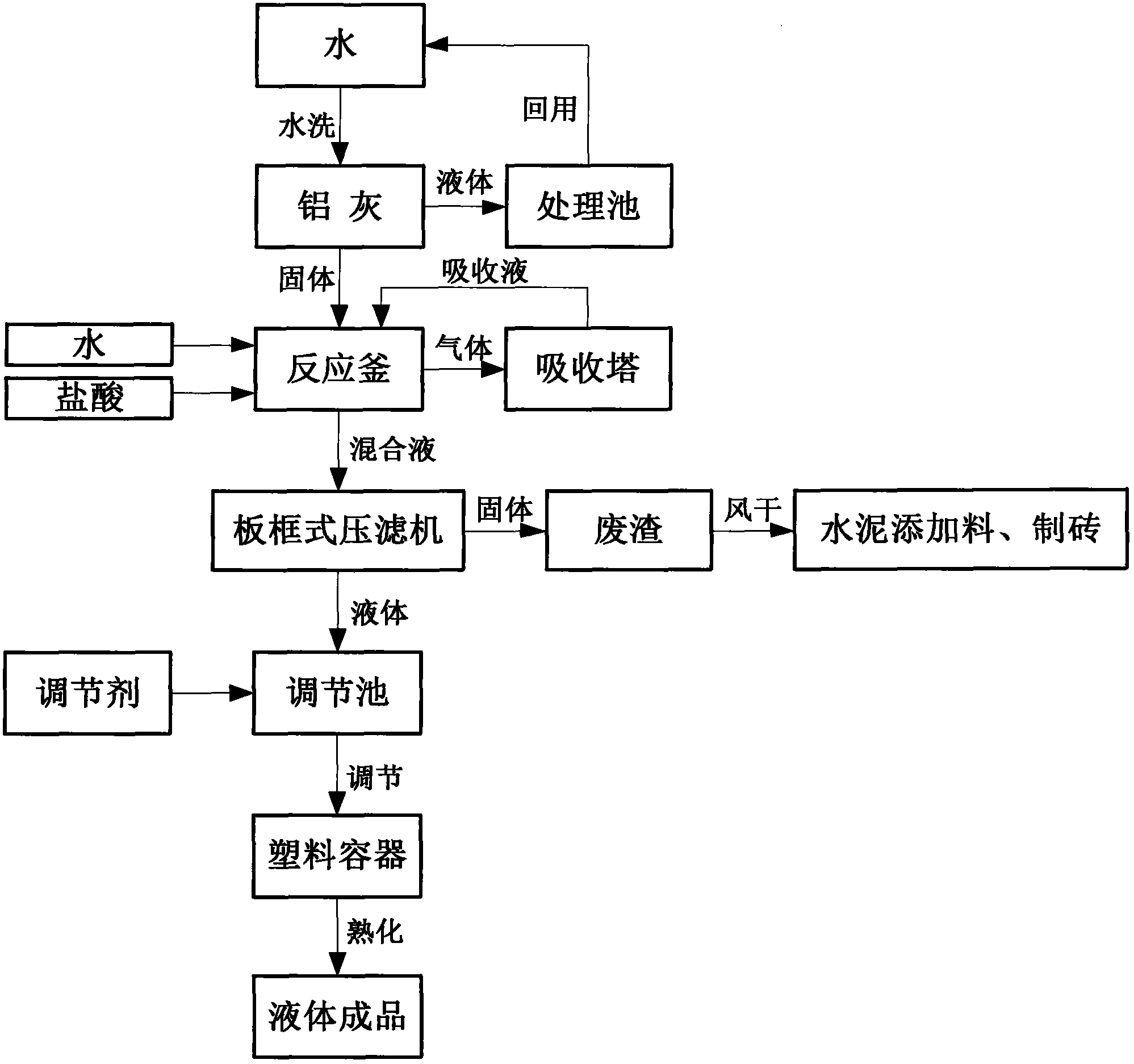

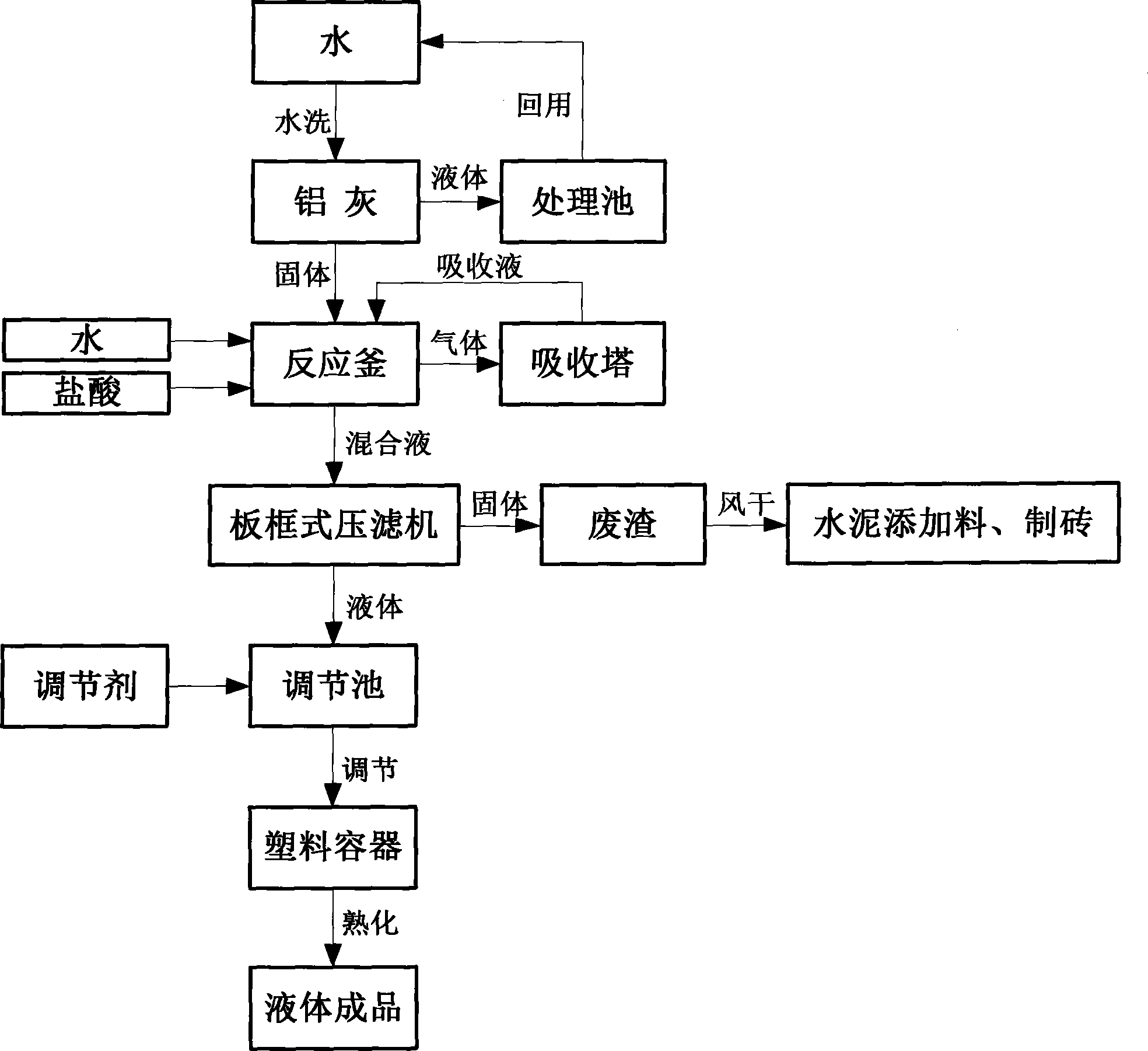

Image

Examples

Embodiment 1

[0022] Embodiment 1: A method for preparing a flocculant liquid polyaluminum chloride by using aluminum ash, which includes the following steps: 1. mix and stir aluminum ash and water at a volume ratio of 1:3, and soak for 8 hours; 2. extract the upper liquid To the sedimentation tank, reuse after treatment, pump the remaining aluminum ash after washing into the reaction kettle; ③According to the volume ratio aluminum ash: hydrochloric acid: water is 1: 2.5: 3.0 to the aluminum ash after washing Add hydrochloric acid and water, stir evenly to form a mixed solution; ④Set the temperature of the reactor to 85°C, and react for 2.5 hours; Continue the reaction in the reaction kettle; ⑥Use the plate and frame filter press to separate the solid and liquid from the reacted mixed solution, and the waste residue can be used as cement production additive or brick-making raw material after air-drying; Add a regulator to adjust the alumina content and basicity of the liquid. Quicklime is u...

Embodiment 2

[0023]Embodiment 2: A kind of method that utilizes aluminum ash to prepare flocculant liquid polyaluminum chloride, it comprises the following steps: ① mix and stir aluminum ash and water according to the volume ratio 1: 4, soak for 7 hours; ② extract the upper layer liquid To the sedimentation tank, reuse after treatment, pump the remaining aluminum ash after washing into the reaction kettle; ③According to the volume ratio of aluminum ash: hydrochloric acid: water is 1: 3.0: 4.0 into the washed aluminum ash Add hydrochloric acid and water, stir evenly to form a mixed solution; ④Set the temperature of the reactor to 90°C, and react for 3 hours; ⑤The gas generated during the reaction process is sprayed and absorbed by the absorption tower. Continue the reaction in the reaction kettle; ⑥Use the plate and frame filter press to separate the solid and liquid from the reacted mixed solution, and the waste residue can be used as cement production additive or brick-making raw material ...

Embodiment 3

[0024] Embodiment 3: A kind of method that utilizes aluminum ash to prepare flocculant liquid polyaluminum chloride, it comprises the following steps: ① mix and stir aluminum ash and water according to the volume ratio 1:5, soak for 5 hours; ② extract the upper layer liquid To the sedimentation tank, reuse after treatment, pump the remaining aluminum ash after washing into the reaction kettle; ③According to the volume ratio of aluminum ash: hydrochloric acid: water is 1: 2.5: 3.5 to the aluminum ash after washing Add hydrochloric acid and water, stir evenly to form a mixed solution; ④Set the temperature of the reactor to 100°C, and react for 2 hours; Continue the reaction in the reaction kettle; ⑥Use the plate and frame filter press to separate the solid and liquid from the reacted mixed solution, and the waste residue can be used as cement production additive or brick-making raw material after air-drying; Add a conditioner to adjust the content and basicity of liquid alumina,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com