Flocculation curing agent, composition thereof and stabilization improvement method of silt type soil

A solidification and soil technology, applied in chemical instruments and methods, solid waste management, sludge treatment, etc., can solve problems such as difficult and rapid treatment, slow solidification strength, and difficult growth and reproduction of plants

Inactive Publication Date: 2010-10-20

株式会社安农津技研 +3

View PDF0 Cites 47 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, such a process is not only complicated but also difficult to handle quickly. It requires complex processes and devices such as large water storage tanks, stirring tanks, and sedimentation tanks, and the power required for operation is also large.

Moreover, the solidified product after solid-liquid separation in such a process cannot exhibit soil strength with strong water retention because it is mixed with an organic flocculant, and it is difficult for plants to grow and reproduce, so it cannot be used as a soil improvement material. Soil improvement materials,

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

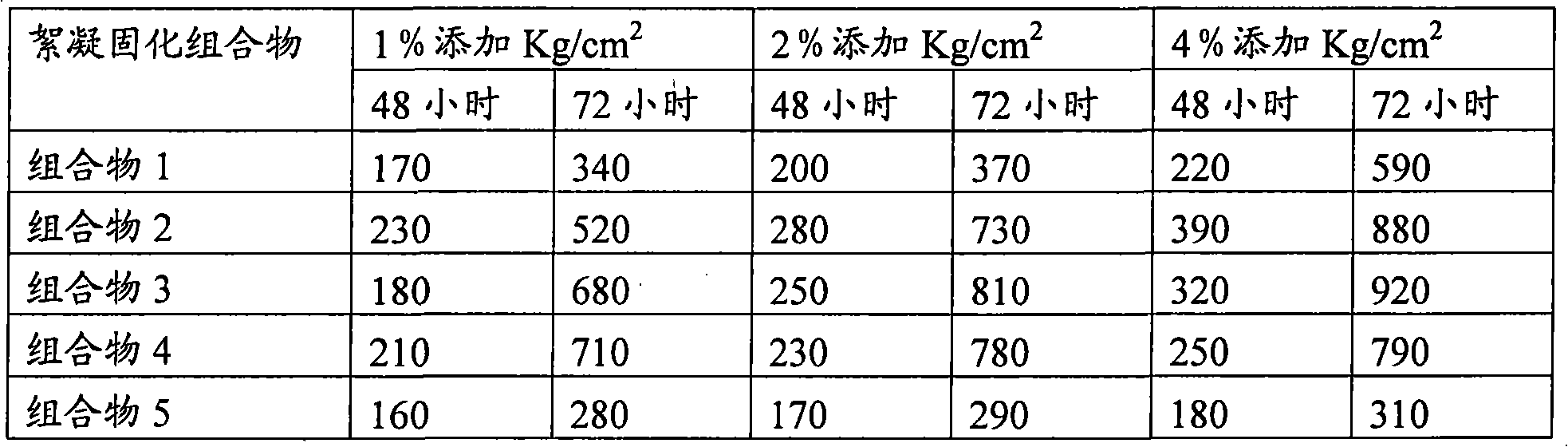

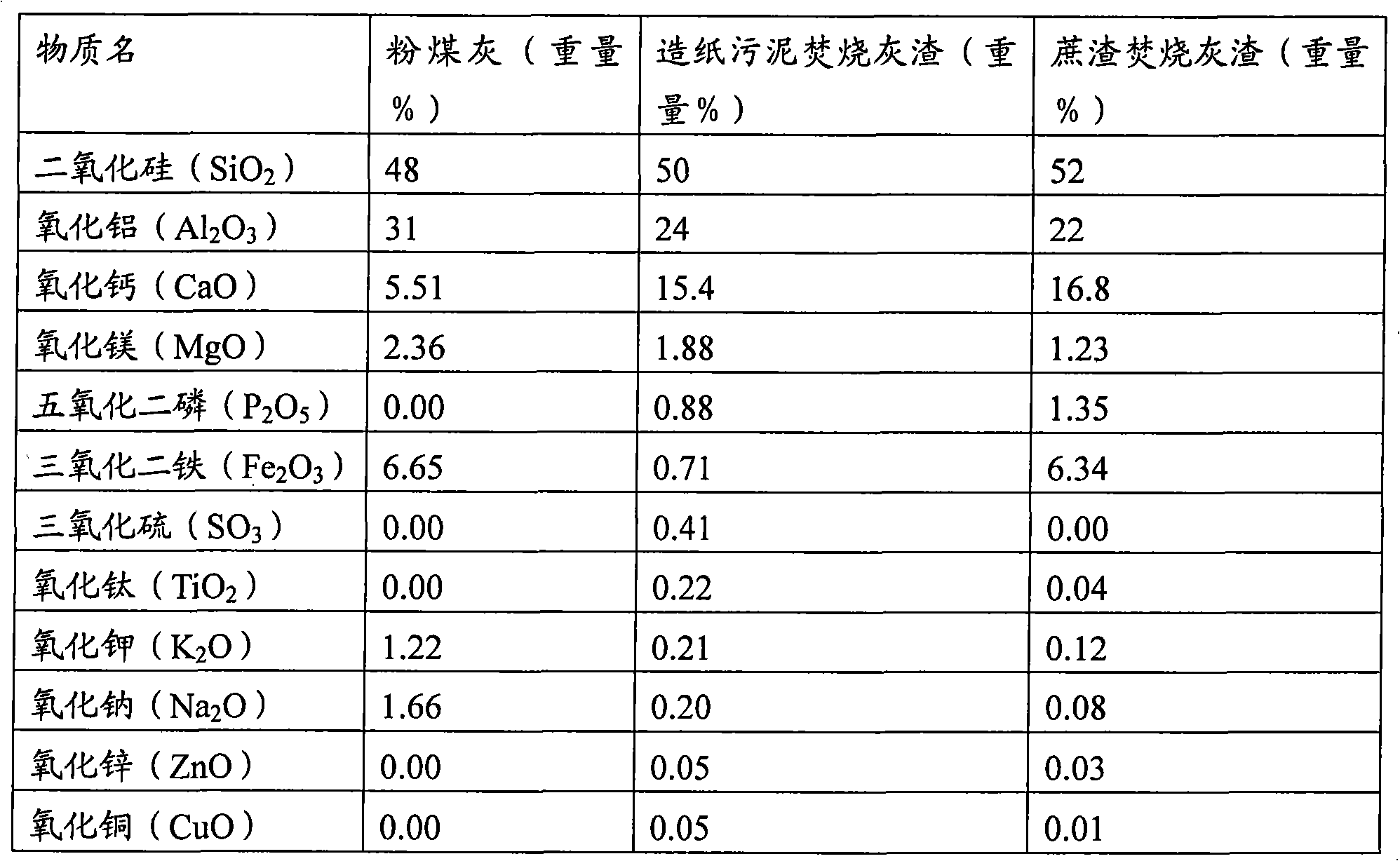

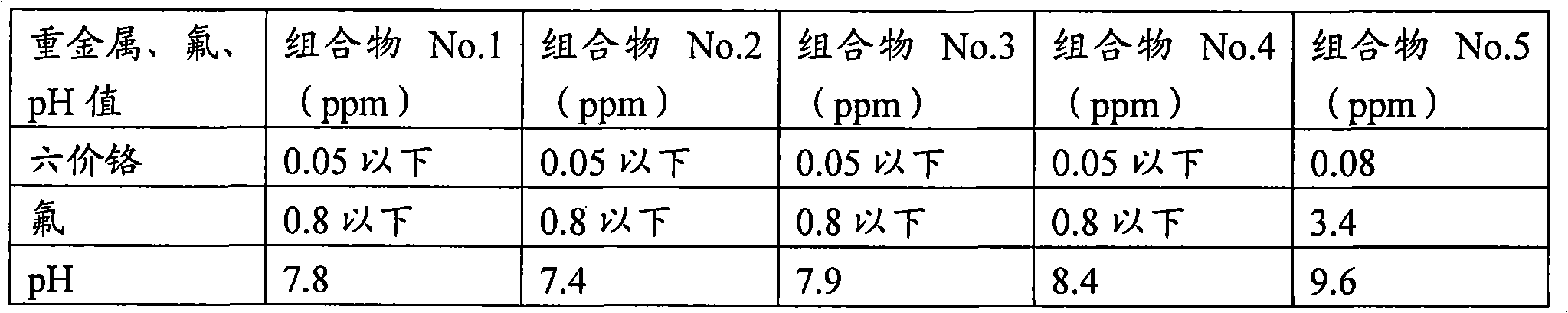

The invention provides a flocculation curing composition of silt type soil and a stabilization improvement method of the silt type soil. The flocculation curing composition comprises flocculation curing agents as active ingredients. The flocculation curing agents are obtained through mixing the following substances as active ingredients: one kind of material or a mixture of fly ash, bottom ash and fly ash of paper making sludge, bottom ash and fly ash of cane trash and bottom ash and fly ash of various kinds of organic sludge, one kind of material or a mixture of powdery oxides, hydrates and hydrosulfates of calcium or magnesium are used as curing auxiliary agents, and one kind of material or a mixture of aluminium sulphate or aluminum chloride as powdery inorganic flocculation agents. The method comprises the following steps: adding the powdery inorganic flocculation curing agents or the composition thereof into the silt type soil with the water content percent of 600 to 5000 weight percent; separating the materials into supernatant fluid and pellet type solid materials after mixing and stirring; and making the pellet type solid materials reach the specified curing intensity to carry out stabilization improvement on the silt type soil.

Description

technical field [0001] The invention relates to the solidification of a flocculation solidification agent and its composition and an improved method for stabilizing muddy soil. Background technique [0002] In recent years, along with the rapid development of the economy, organic substances exceeding the purification capacity of the natural ecosystem have flowed into rivers, lakes, harbors, etc., and the accumulation of organic humus substances and fine particle soil has caused environmental damage to the natural ecosystem. Especially in closed waters, due to the accumulation of these substances in the bottom mud, the bottom of the water falls into an oxygen-poor state, resulting in a state where microorganisms, fish, plants, etc. cannot grow and reproduce, and various problems that have a bad impact on agriculture and fishery are becoming more and more serious. significantly. In order to solve the problem of such organic humic sludge deposits, it is proposed to use inorgan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F11/00C04B28/04C04B18/30

CPCY02W30/91

Inventor 加藤忠哉高野穰江草清行

Owner 株式会社安农津技研

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com