Preparation method of nanometer tin oxide fibre air-sensitive film

A nano-tin oxide and nano-fiber membrane technology, applied in the direction of material electrochemical variables, can solve problems such as difficult redissolving, difficult spinning solution configuration, and polyvinylpyrrolidone precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

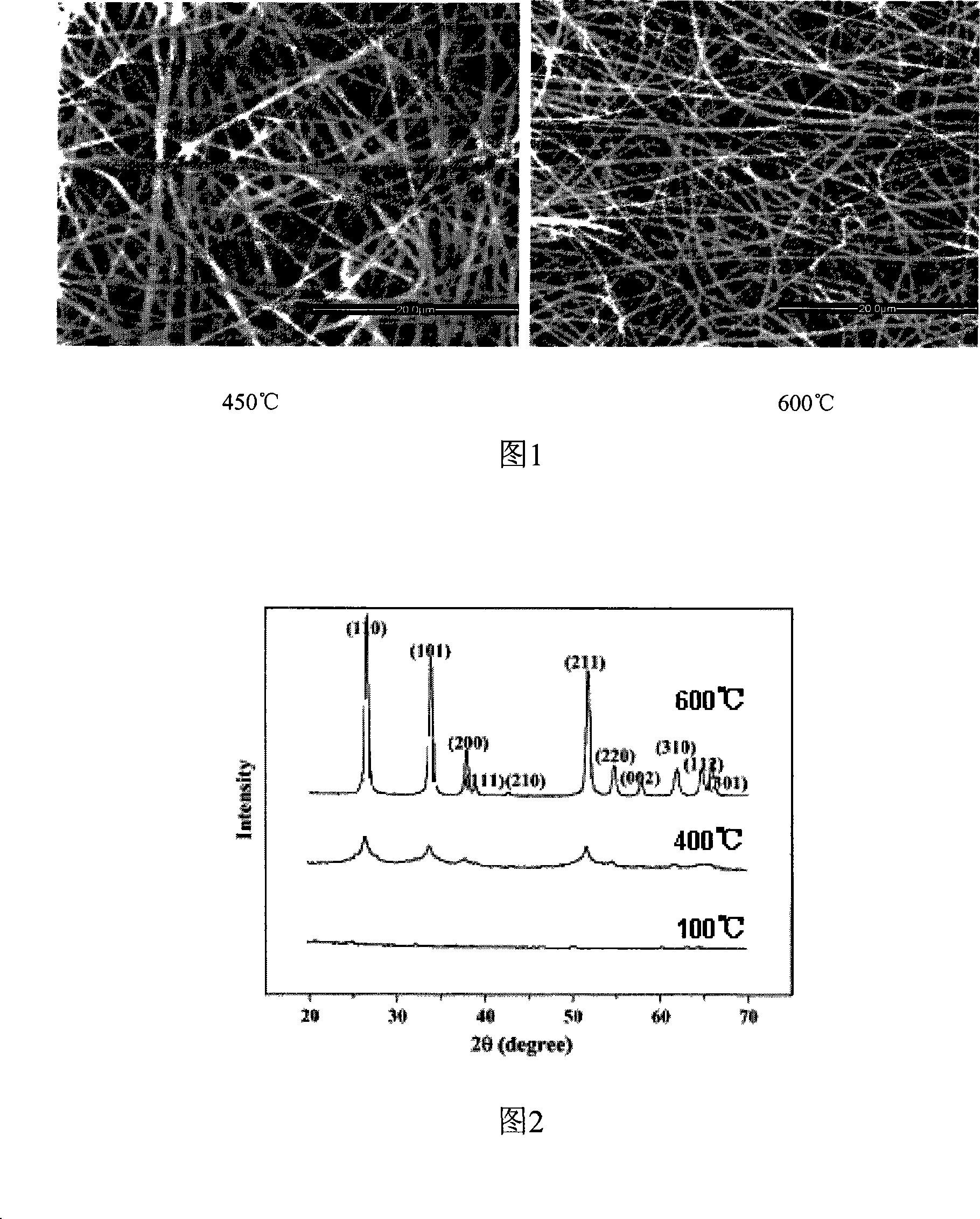

Embodiment 1

[0025] Take 3 g of polyvinylpyrrolidone with a viscosity-average molecular weight of 600,000 and pour it into 57 mL of N,N-dimethylformamide solvent, stir at high speed until completely dissolved, and prepare a 5% polyvinylpyrrolidone / DMF solution. Weigh 1g of tin chloride tetrahydrate and dissolve it in 9mL of ethanol, then mix the two solutions and stir at high speed for 1 hour to obtain a sol-gel electrospinning solution; inject the prepared sol-gel spinning solution into the electrospinning device In the process, the aluminum chloride / polyvinylpyrrolidone nanofiber membrane was electrospun under the conditions of a voltage of 25kV, an extrusion speed of 10mL / min, and a receiving distance of 10cm; finally, the prepared tin chloride / polyvinylpyrrolidone nanofiber membrane Place in a muffle furnace, raise the temperature to 450°C at a rate of 50°C / h, and dry for 5h to obtain a dry tin chloride nanofiber gas-sensitive membrane.

Embodiment 2

[0027] Take 3g of polyvinylpyrrolidone with a viscosity-average molecular weight of 900,000 and pour it into 47mL N, N-dimethylformamide solvent, stir at a high speed until completely dissolved, and prepare a 6% polyvinylpyrrolidone ethanol / DMF solution. Weigh 2g of tin chloride tetrahydrate and dissolve it in 8mL of ethanol, then mix the two solutions and stir at high speed for 1 hour to obtain a sol-gel electrospinning solution; inject the prepared sol-gel spinning solution into the electrospinning device In the process, the aluminum chloride / polyvinylpyrrolidone nanofiber membrane was electrospun under the conditions of a voltage of 30kV, an extrusion speed of 5mL / min, and a receiving distance of 10cm; finally, the prepared tin chloride / polyvinylpyrrolidone nanofiber membrane Place it in a muffle furnace, raise the temperature to 450°C at a rate of 50°C / h, and calcinate for 5h to obtain a nano-tin oxide fiber gas-sensitive film.

Embodiment 3

[0029]Take 3g of polyvinylpyrrolidone with a viscosity-average molecular weight of 1.1 million and pour it into 40mL N, N-dimethylformamide solvent, stir at a high speed until completely dissolved, and prepare a 7% polyvinylpyrrolidone / DMF solution, weighing Dissolve 2 g of tin chloride tetrahydrate in 10 mL of ethanol, then mix the two solutions and stir at high speed for 1 hour to obtain a sol-gel electrospinning solution; inject the prepared sol-gel spinning solution into the electrospinning device , at a voltage of 30kV, an extrusion speed of 8mL / min, and a receiving distance of 15cm, electrospun into an aluminum chloride / polyvinylpyrrolidone nanofiber membrane; finally, the prepared tin chloride / polyvinylpyrrolidone nanofiber membrane was placed In a muffle furnace, the temperature was raised to 600° C. at a rate of 50° C. / h, and calcined for 5 hours to obtain a nano-tin oxide fiber gas-sensing membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com