Preparation method for bisphenol F

A phenol and cation exchange technology, which is applied in the preparation of organic compounds, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of many side reactions and influence on yield, and achieve convenient operation , easy separation and recovery, simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Catalyst Preparation

[0026] The cation exchange resin was successively soaked with saturated sodium chloride solution, dilute sodium hydroxide solution with a mass concentration of 2% to 10%, and dilute hydrochloric acid solution with a mass concentration of 2% to 10%, rinsed and dried, and then put 25g into a three-necked flask. Add AlCl 3 and TiCl 4 impregnated with anhydrous ethanol solution, the molar ratio of aluminum trichloride and titanium tetrachloride is Al / Ti=0.4, the temperature of the water bath in the three-necked flask is controlled at 78°C, stirred, and refluxed for 12 to 20 hours. After impregnation, cool down to room temperature naturally, add deionized water, and stir to make the excess AlCl 3 、TiCl 4 hydrolysis. The resin was filtered, washed with deionized water until there was no Cl ion (detected with silver nitrate), dried at 100°C to constant weight, and placed in a desiccator for later use.

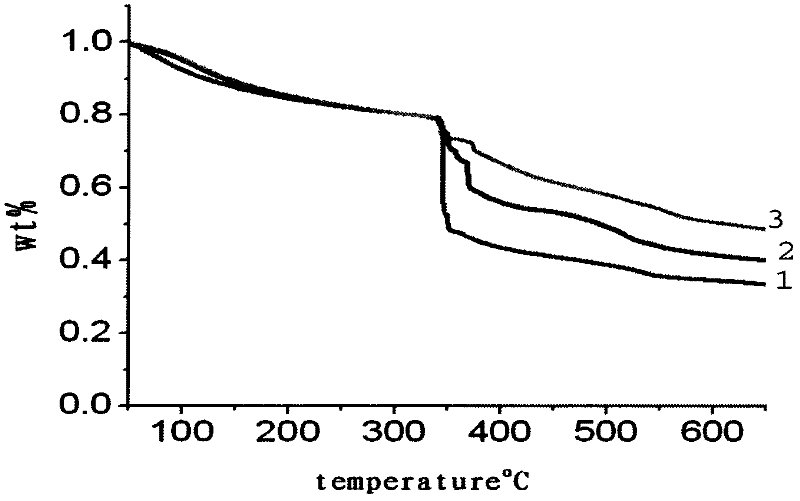

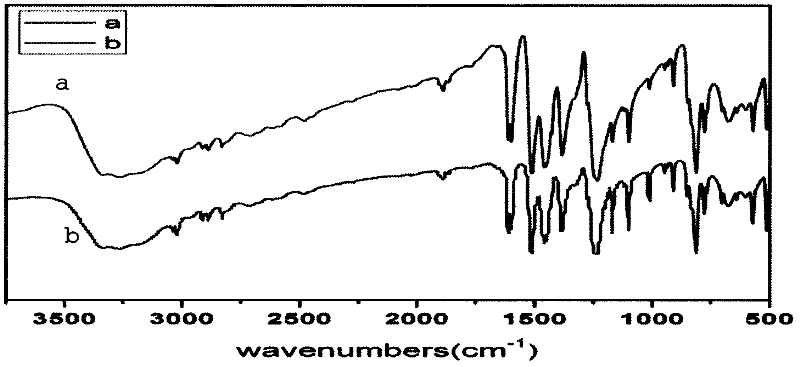

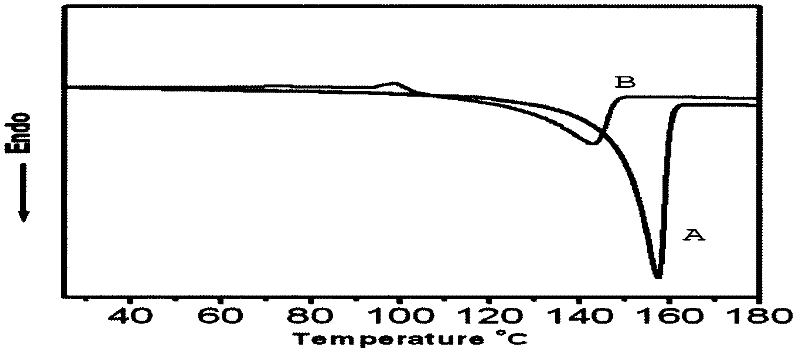

[0027] attached figure 1 DescriptionAlCl ...

Embodiment 2

[0032] Similar to Example 1, the difference is that the 0.5-fold xylene crystallization reaction concentrate is used, and the purity of 4,4'-BPF measured by gas chromatography internal standard method reaches 90.4%.

Embodiment 3

[0034] Similar to Example 1, the difference is that the temperature of the water bath in the preparation of the catalyst is controlled at 85° C., and the content of bisphenol F measured by the gas chromatography internal standard method reaches 81.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com