Superfine panax pseudoginseng powder cellulose fiber, and preparation method and application of cellulose fiber

A technology of cellulose fiber and ultrafine notoginseng powder, which is applied in the field of its preparation, ultrafine notoginseng powder cellulose fiber, can solve the problem of difficult to prepare fabrics that directly contact human skin, low adhesion rate of functional components, natural Fiber comparison and other issues to achieve the effect of improving human microcirculation, promoting skin microcirculation, and reducing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

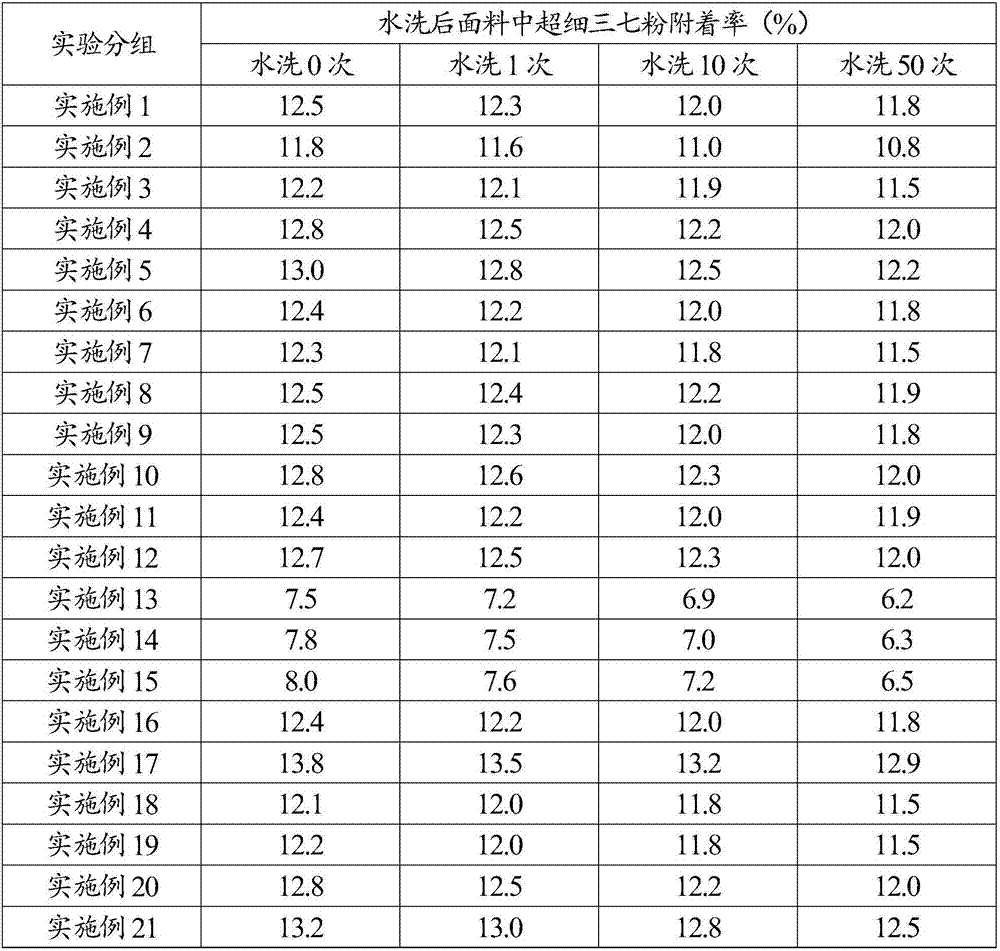

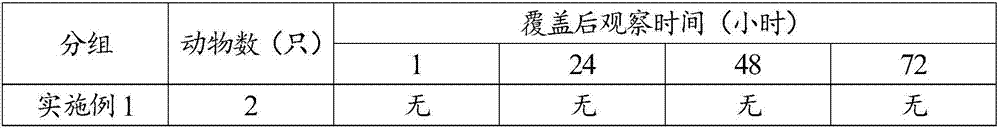

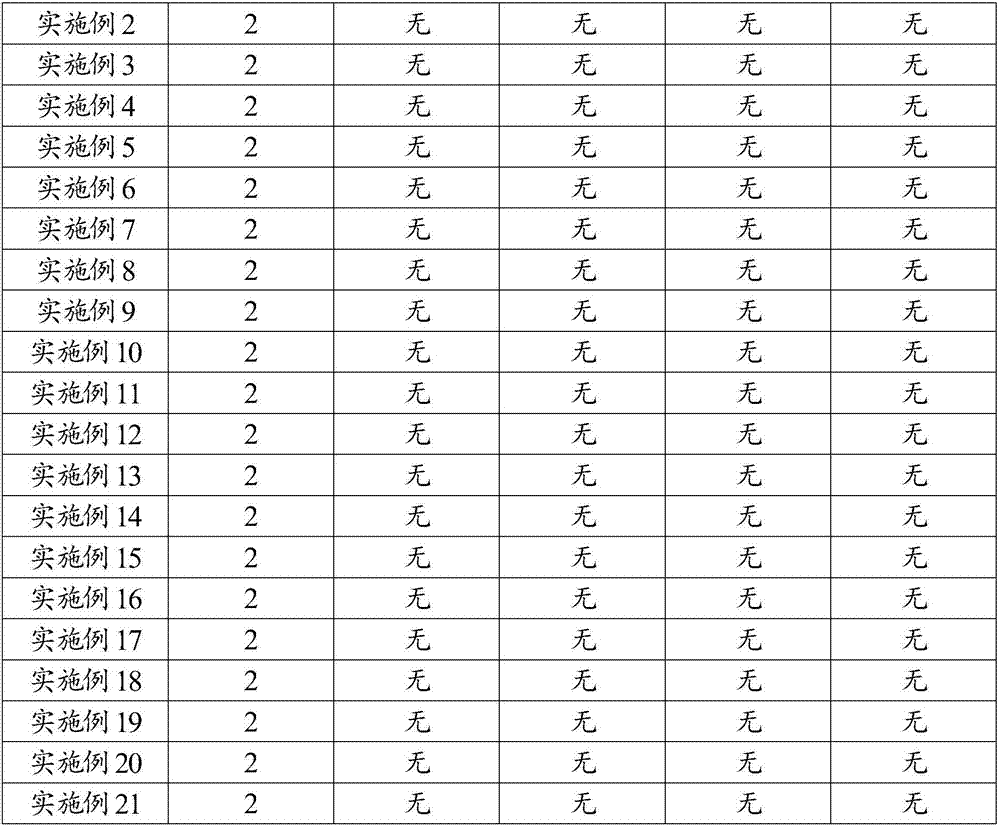

Examples

Embodiment 1

[0031] A kind of preparation method of superfine notoginseng powder cellulose fiber described in the present embodiment, comprises the following steps:

[0032] (1) In terms of weight percentage, take 20% of Panax notoginseng powder, add 10% of dispersant alkylbenzene sulfonate, add deionized water to 100%, after mixing evenly, grind the mixed system for 2.5h, stir , wherein the grinding and stirring temperature is controlled at 45° C. to obtain a Panax notoginseng powder dispersion; the particle size of the Panax notoginseng powder is 800-1200 mesh;

[0033] (2) the notoginseng powder dispersion liquid that step (1) obtains is injected by pre-spinning injection by wood fiber or cotton linter, after alkalization, aging, sulfonation, dissolves in lye again and makes viscose, described The volume percentage of the Panax notoginseng powder dispersion relative to the viscose is 10%, fully mixed by a static mixer, and then wet-spun and post-treated to obtain the ultra-fine Panax no...

Embodiment 2~ Embodiment 5

[0035] A kind of preparation method of superfine notoginseng powder cellulose fiber described in embodiment 2~embodiment 5, and the difference of embodiment 1 is respectively:

[0036] In step (1), by weight percentage, take 5% of notoginseng powder, add 2% of dispersant alkylbenzene sulfonate, add deionized water to 100%, and mix evenly.

[0037] In step (1), by weight percentage, take 10% of notoginseng powder, add 5% of dispersant alkylbenzene sulfonate, add deionized water to 100%, and mix evenly.

[0038] In step (1), by weight percentage, take 30% of notoginseng powder, add 15% of dispersant alkylbenzene sulfonate, add deionized water to 100%, and mix evenly.

[0039]In step (1), by weight percentage, take 40% notoginseng powder, add 20% dispersant alkylbenzene sulfonate, add deionized water to 100%, and mix evenly.

Embodiment 6~ Embodiment 8

[0041] A kind of preparation method of superfine notoginseng powder cellulose fiber described in embodiment 6~embodiment 10, and the difference of embodiment 1 is respectively:

[0042] In step (1), the dispersant added is polyoxyethylene alkylphenol ether.

[0043] In step (1), the dispersant added is alkyl pyridine chloride.

[0044] In step (1), the added dispersant is alkylbenzene sulfonate and polyoxyethylene alkylphenol ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com