Nanofiber dispersion, method for producing nanofiber dispersion, powdery nanofibers obtained from dispersion, resin composition including said powdery nanofibers, and molding material for 3D printer in which said resin composition is used

A technology of nanofibers and manufacturing methods, which is applied in the field of modeling materials for 3D printers, can solve the problems of insufficient dispersion of nanofillers and inability to fully exert the functions of nanofillers, and achieve excellent surface smoothness, improved elastic modulus, and improved uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0177]

[0178] The molding material of the present invention is prepared using the dispersion obtained as described above and the (C) resin component.

[0179] In this case, the method for producing the resin composition of the present invention is to knead with (C) the resin component after drying the dispersion mainly composed of (A) nanofibers and (B) dispersant. As a specific example at this time, after freeze-drying, drying under reduced pressure, heat drying or spray drying the dispersion (emulsion or slurry) mainly composed of (A) nanofibers and (B) dispersant, Knead with (C) resin component.

[0180] The drying method of the dispersion, the kneading method of the powdery nanofibers and the (C) resin component, and the blending of other additives are as described above.

[0181]

[0182] The compounding ratio of each component in the molding material of the present invention is in terms of solid content. Usually, (A) nanofibers such as cellulose nanofibers are 0.5...

Embodiment 1~3、 comparative example 1~3

[0201] Using K-2 manufactured by HIROSHIMA METAL & MACHINERY Co., Ltd. as a medialess disperser, the slurry that was dispersed with purified water, cellulose nanofibers, and a dispersant as a dispersion medium was put into the medialess disperser, and was rotated at a peripheral speed of 30 m / s to circulate, promote the dispersion and defibration of cellulose by shearing, and obtain a dispersed and stable cellulose nanofiber dispersion.

[0202] That is, using the above-mentioned apparatus, cellulose nanofibers (BiNFi-s, manufactured by SUGINOMACHINE Co., Ltd.) containing 0.1% by weight and polymethacryloyl oxide at different concentrations (0.004% by weight to 0.01% by weight) as a dispersant The aqueous dispersion of ethyl ethyl phosphorylcholine (LIPIDURE HM, manufactured by NOF Corporation) was repeatedly subjected to 5 times of mediumless dispersion treatment to prepare cellulose nanofiber dispersion, and the ζ-potential and dispersibility were measured, and the sedimenta...

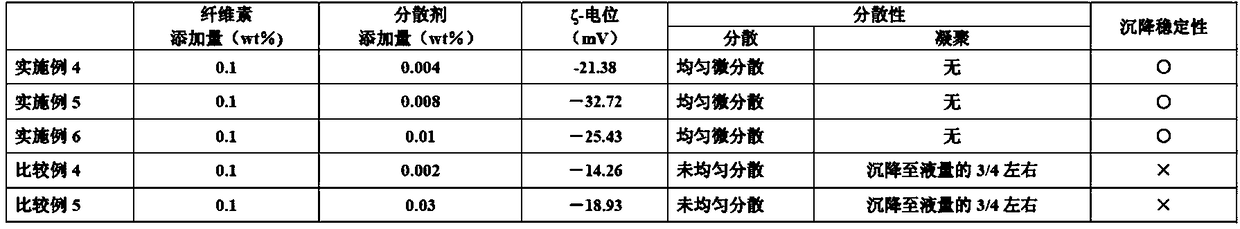

Embodiment 4~6、 comparative example 4~5

[0206] The type of dispersant was changed to polybutyl methacrylate-methacryloyloxyethyl phosphorylcholine (LIPIDURE PMB, manufactured by NOF Corporation), except that it was performed in the same manner as in Example 1 to prepare Cellulose Nanofiber Dispersion. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com