Method for producing cellulose ether derivative

A technology of cellulose ether and manufacturing method, applied in the field of manufacture of cellulose ether derivatives, can solve the problems of insufficient solubility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

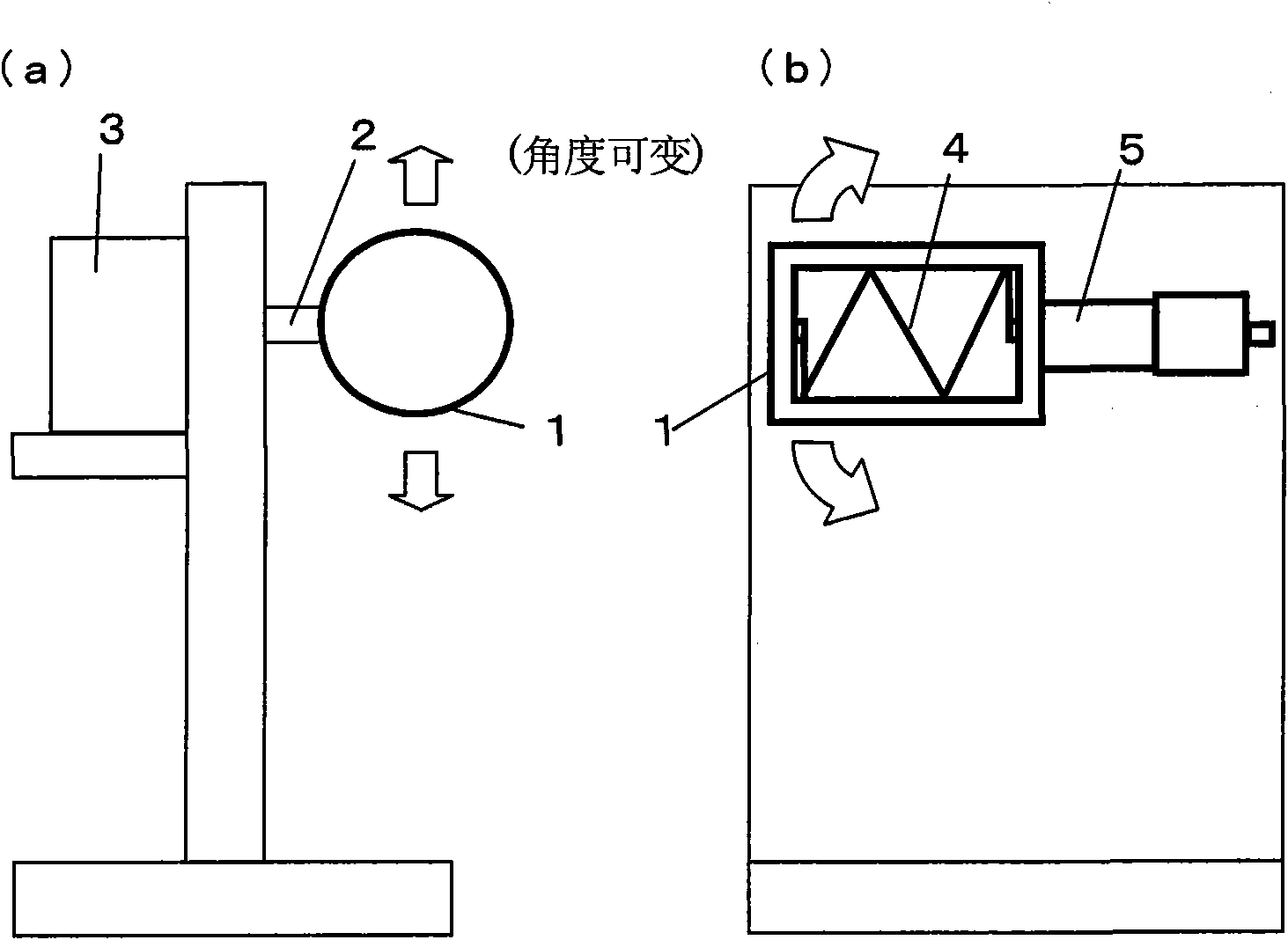

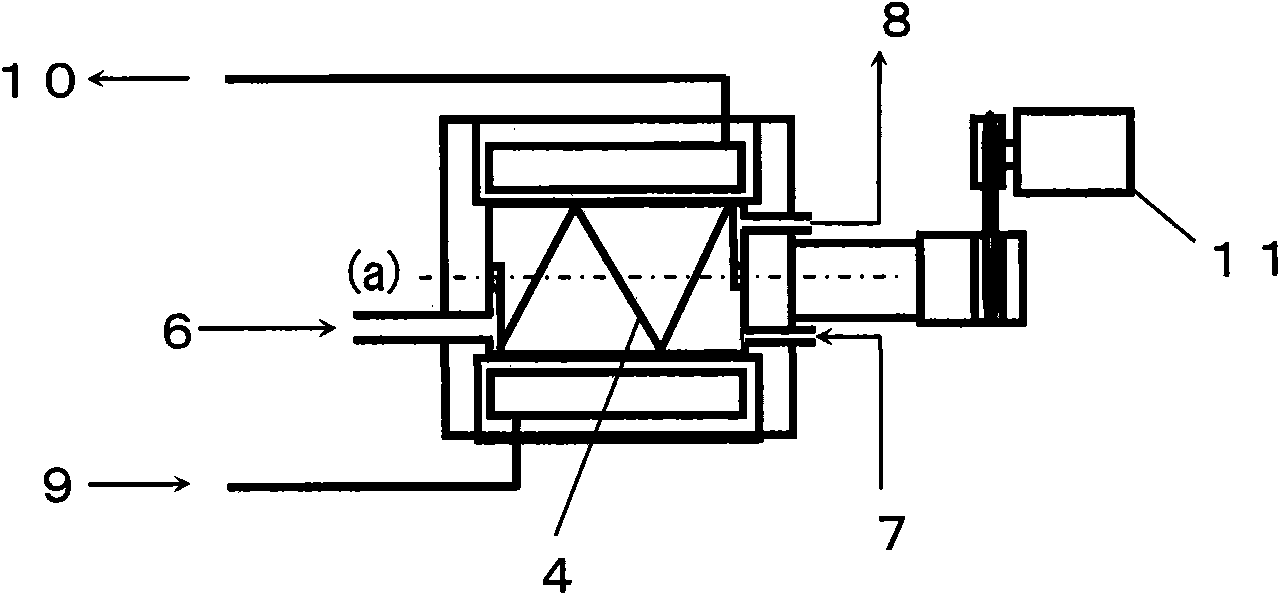

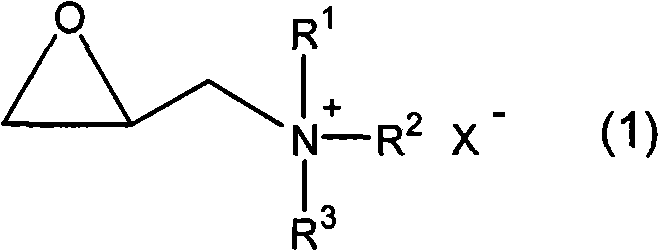

Method used

Image

Examples

preparation example Construction

[0041] [Preparation of low-crystalline powdered cellulose]

[0042] It is known that cellulose generally has several crystal structures, and the degree of crystallinity is defined from the ratio of partially existing amorphous parts and crystalline parts, however, the "crystallinity" in the present invention means the degree of crystallinity derived from the crystal structure of natural cellulose. The type I crystallinity is defined by the crystallinity expressed by the following calculation formula (1) obtained from the powder X-ray diffraction spectrum.

[0043] Crystallinity (%)=[(I 22.6 -I 18.5 ) / I 22.6 〕×100 (1)

[0044] 〔I 22.6 Indicates the diffraction intensity of the lattice plane (002 plane) (diffraction angle 2θ=22.6°) in X-ray diffraction, and I 18.5 Represents the diffraction intensity of the amorphous portion (diffraction angle 2θ=18.5°). 〕

[0045] The "low crystallinity" of the low crystallinity powdery cellulose in the present invention means the state ...

Embodiment

[0146] (1) Moisture content relative to cellulose

[0147] The moisture content relative to cellulose was measured at 150° C. using an infrared moisture meter “FD-610” manufactured by Kett Scientific Research Institute.

[0148] In order to determine the most suitable water content of the cellulose in the present invention when reacting with the epoxy compound of the present invention, after adding a predetermined amount of water to the amorphous powder cellulose obtained in Production Example 1 described later, the Stir and vibrate, and repeatedly observe the agglutination state according to visual inspection.

[0149] As a result, it was judged that although the produced amorphous powder cellulose contains at least 5% by mass of water, in order to make the cellulose react in a fluid powder state, the water content relative to the cellulose is preferably 100% by mass. % or less, more preferably 80 mass % or less, most preferably 50 mass % or less, particularly preferably 30 ...

manufacture example 1

[0173] Manufacturing Example 1 (Manufacturing of Amorphized Powdered Cellulose)

[0174] A wood pulp sheet (pulp sheet manufactured by Borregaard, crystallinity: 74%) was cut into pieces by a shredder (manufactured by Meiko Shokai Co., Ltd., "MSX2000-IVP440F").

[0175] Next, the resulting flake pulp was fed into a twin-screw extruder (manufactured by Suehiro EPM, "EA-20") at a speed of 2 kg / hr, and was cut at a shear rate of 660 sec. -1 , The screw speed is 300rpm, and cooling water is introduced from the outside for one-pass treatment to make it into powder.

[0176] Next, the obtained powdered cellulose was put into a batch-type medium agitation mill ("Sand mill" manufactured by Igarashi Machinery Co., Ltd.: container capacity 800mL, filled with 5mmφ zirconia beads 720g, filling rate 25%, stirring blade diameter 70mm). Cooling water was passed into the container jacket, and pulverization was carried out for 2.5 hours at a stirring speed of 2000 rpm and a temperature of 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com