Method for producing cellulose and polypeptide protein feed by fermenting with Aspergillus awamori

A technology of Aspergillus awamori and cellulase, which is applied in the field of preparation of cellulase and polypeptide protein feed produced by fermentation of Aspergillus awamori strains, and can solve problems such as anemia, death, and limitation of peanut meal feeding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

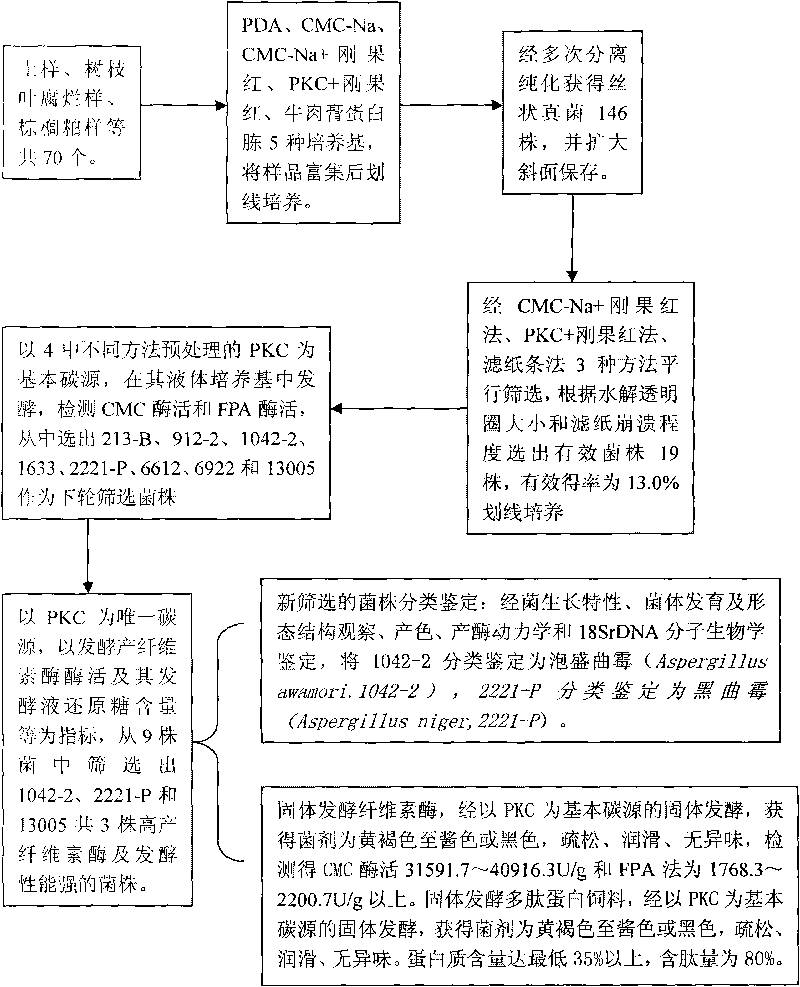

[0056] Example 1: Isolation, purification and screening of strains

[0057] A. Sampling and enrichment: The first is sampling. From the collection to 70 samples, the samples come from soil samples, dead branches and rotten leaves (cypress, pine, palm, etc.), PKC samples, and rotten plant stems and leaves (bamboo). Leaves, grass, etc.) etc. After sampling, use a sterile bag for packaging. Store in the refrigerator at 0~4℃. The second is enrichment. PKC pretreated by extrusion and gas explosion is used as the only carbon source, and the enrichment medium is configured with inorganic salt. Each test tube is filled with 4ml and sterilized. After sterility test, 1g sample was inserted, placed at 20~45℃, 220r / min shaking enrichment culture for 5~7 days. The inoculation of each medium was repeated once for a total of 280 culture tubes.

[0058] Isolation and purification of strain B: a. After separation, after enrichment and culture, each test tube is lined on three plates with 5 medi...

Embodiment 2

[0060] Example 2: Classification and identification of strains

[0061] In the process of separation and screening, we noticed the growth characteristics, morphological structure and color production of strain 1042-2. In addition to the above research, the use of culture medium, biomass and enzyme production kinetics research, electron microscopy and scanning electron microscopy observation, and 18SrDNA molecular biology identification have been added. The results are as follows.

[0062] 1042-2 On the PDA plate medium, the hyphae are initially white and fluffy, and grow sparsely radiating to the surroundings; they gradually become yellowish-gray, and the colonies are abnormally thick and dense, such as Pic 4-1 ; Subsequently, the colony turns brown to reddish brown or dark brown; the conidia are brown reddish brown or dark brown, and there are a lot of them. The conidial socket is head-shaped, with an opening and thorns outside. The diameter of the conidia is 3.5μm. Such as Figu...

Embodiment 3

[0064] Example 3: Enzyme production test by solid fermentation

[0065] Three strains of 1042-2, 2221-P and 13005 obtained by three-stage screening were subjected to a shallow plate solid fermentation test for enzyme production. The formula of the shallow plate solid medium is as described in the content of the invention. After testing, the CMC enzyme activity and FPA enzyme activity produced by the two strains 1042-2 and 2221-P were higher than those produced by 13005. The applicant selected the two strains 1042-2 and 2221-P for further shallow plate fermentation experiments. The test results averaged that the CMC enzyme activity of 1042-2 was 20331.3 U / g, the FPA enzyme activity was 1116.6 U / g; the CMC enzyme activity of 2221-P was 23431.0 U / g, and the FPA enzyme activity was 966.4 U / g; 13005 The CMC enzyme activity was 6299.4 U / g, and the FPA enzyme activity was 679.9 U / g. After comprehensive evaluation and analysis, the newly screened strains of 1042-2 and 2221-P were continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com