Continuously annealed or hot galvanized cold rolled transformation induced plasticity steel plate and preparation method thereof

A phase change induced plasticity and hot-dip galvanizing technology, which is applied in heat treatment equipment, heat treatment furnaces, manufacturing tools, etc., can solve the problems of low strength of TRIP steel and increase the cost of steel plates, etc., and achieve the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

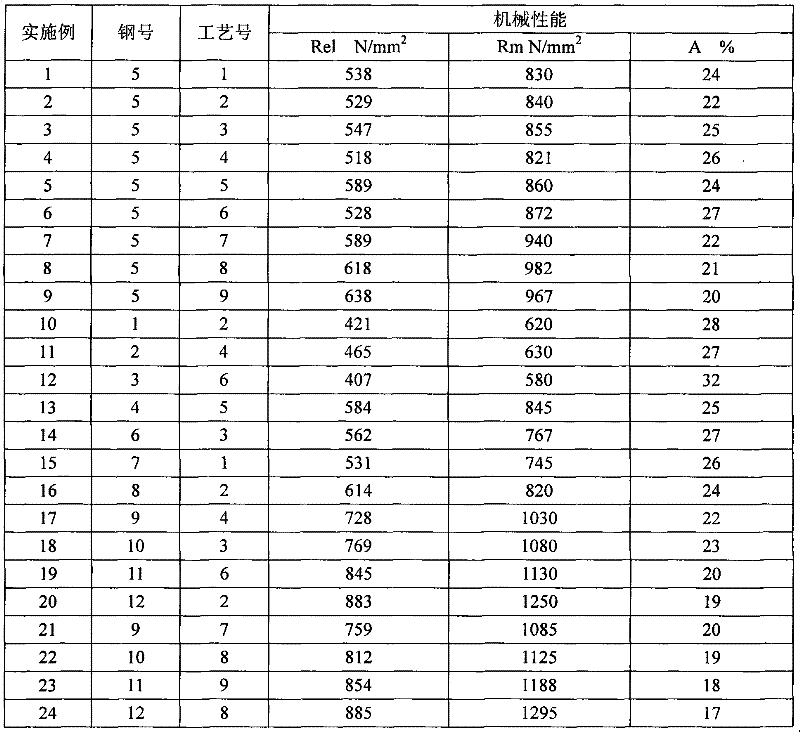

[0049] The present invention will be further described below by way of examples.

[0050] The following examples are given to illustrate the present invention more specifically. However, the present invention is not limited by the following examples, and can also be implemented with appropriate changes within the scope of the purpose described, all of which are included in the technical scope of the present invention.

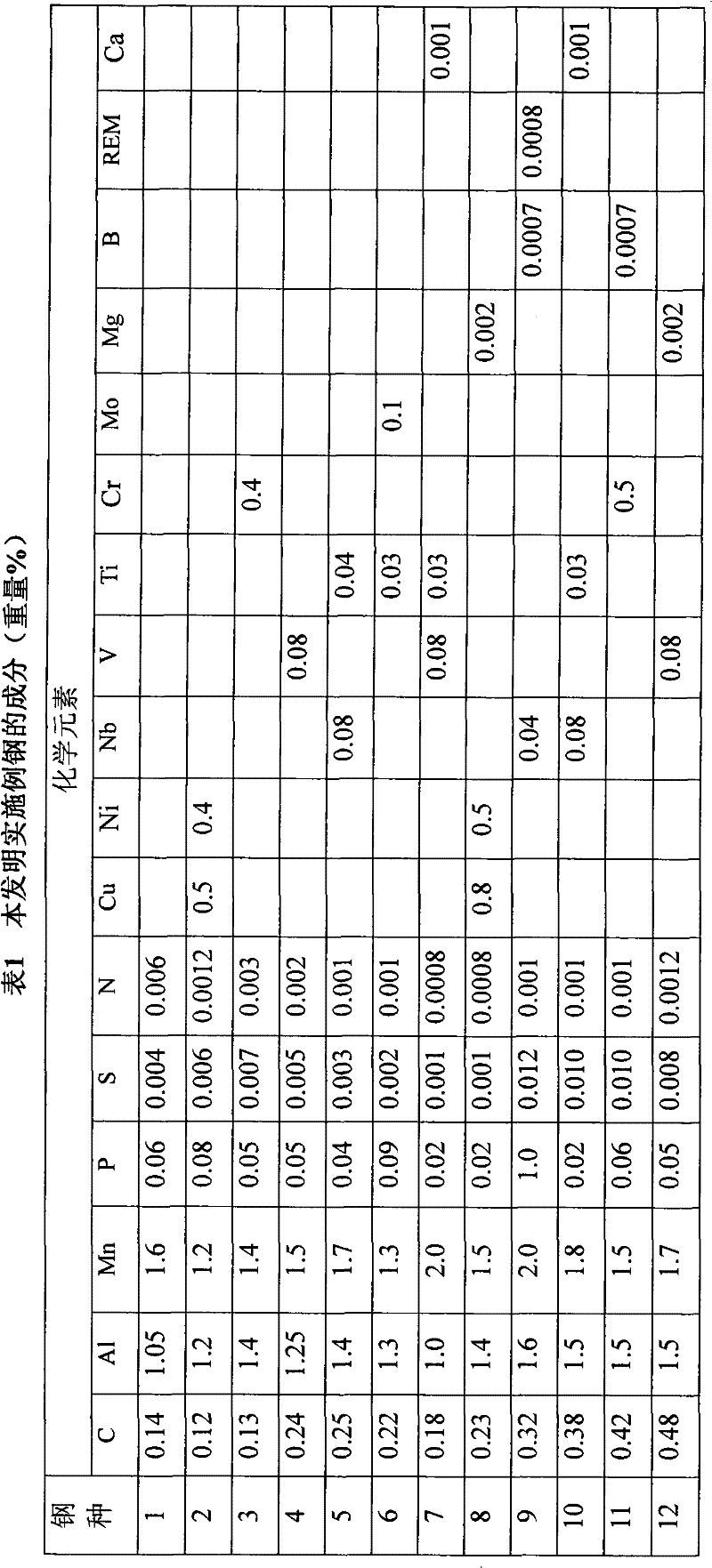

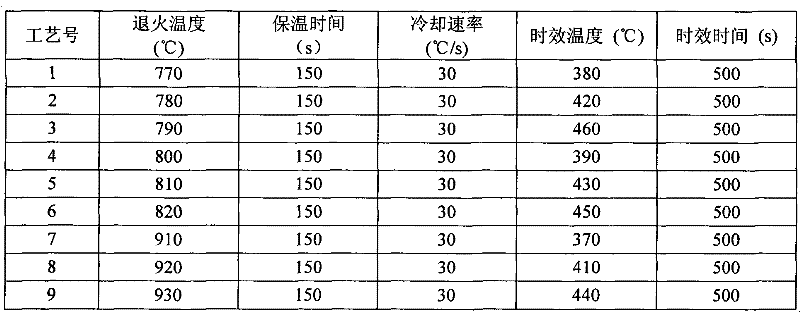

[0051] Table 1 is the chemical composition of the steel of the embodiment of the present invention (the balance is iron and unavoidable impurities). After obtaining the continuous casting slab, hot rolling is implemented. After heating at 1250° C. for 2 hours, hot rolling is carried out. The final rolling temperature is 880° C., the coiling temperature is 650° C., and then air-cooled to room temperature. The thickness of the hot-rolled sheet is 3.5 mm. Then cold rolling is carried out, and the thickness of the cold rolled plate is 1.5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com