Polyvinyl alcohol fiber and preparation method as well as application thereof

A polyvinyl alcohol fiber and wet spinning technology, which is applied in the fields of fiber chemical characteristics, spinning solution preparation, wet spinning method, etc., can solve problems such as unsatisfactory applications, and achieve good uniformity, simple process, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]Put 1000kg of polyvinyl alcohol with a degree of polymerization of 1820 and a degree of alcoholysis of 99.6mol%, and 5700kg of water, into a stainless steel dissolution kettle, add 1.0-1.2kg of boric acid, and dissolve for 4 hours at a temperature of 98-100°C and a pressure of 0.1pa under stirring Afterwards, it is pumped and filtered, degassed under normal pressure for 480 minutes, and the degassing temperature is 97°C, and the temperature of the spinning stock solution is 97°C; through a metering pump, it is sprayed out through a spinneret with an aperture of 0.2mm and 3000 holes. The ingot is 1000~1100ml / min., directly enters the coagulation bath of sodium hydroxide aqueous solution at 45±2℃, the spinneret is stretched -35 times, and then the fiber is stretched by the godet to a certain extent, then acid bath neutralization, damp heat Stretch 2.0 times, then wash with water to remove Glauber’s salt, sulfuric acid and excess boric acid in the tow, and then oil it, so th...

Embodiment 2~8

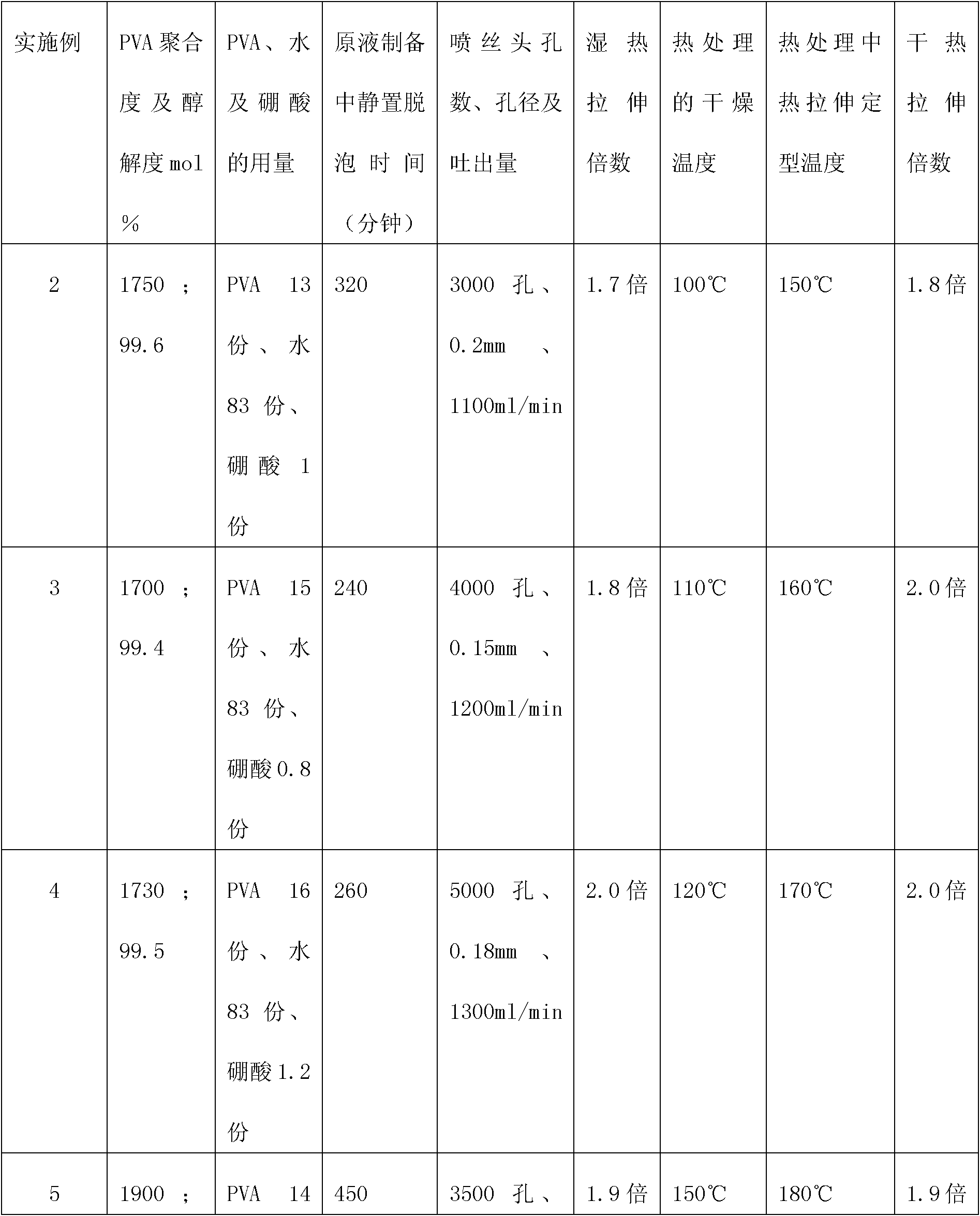

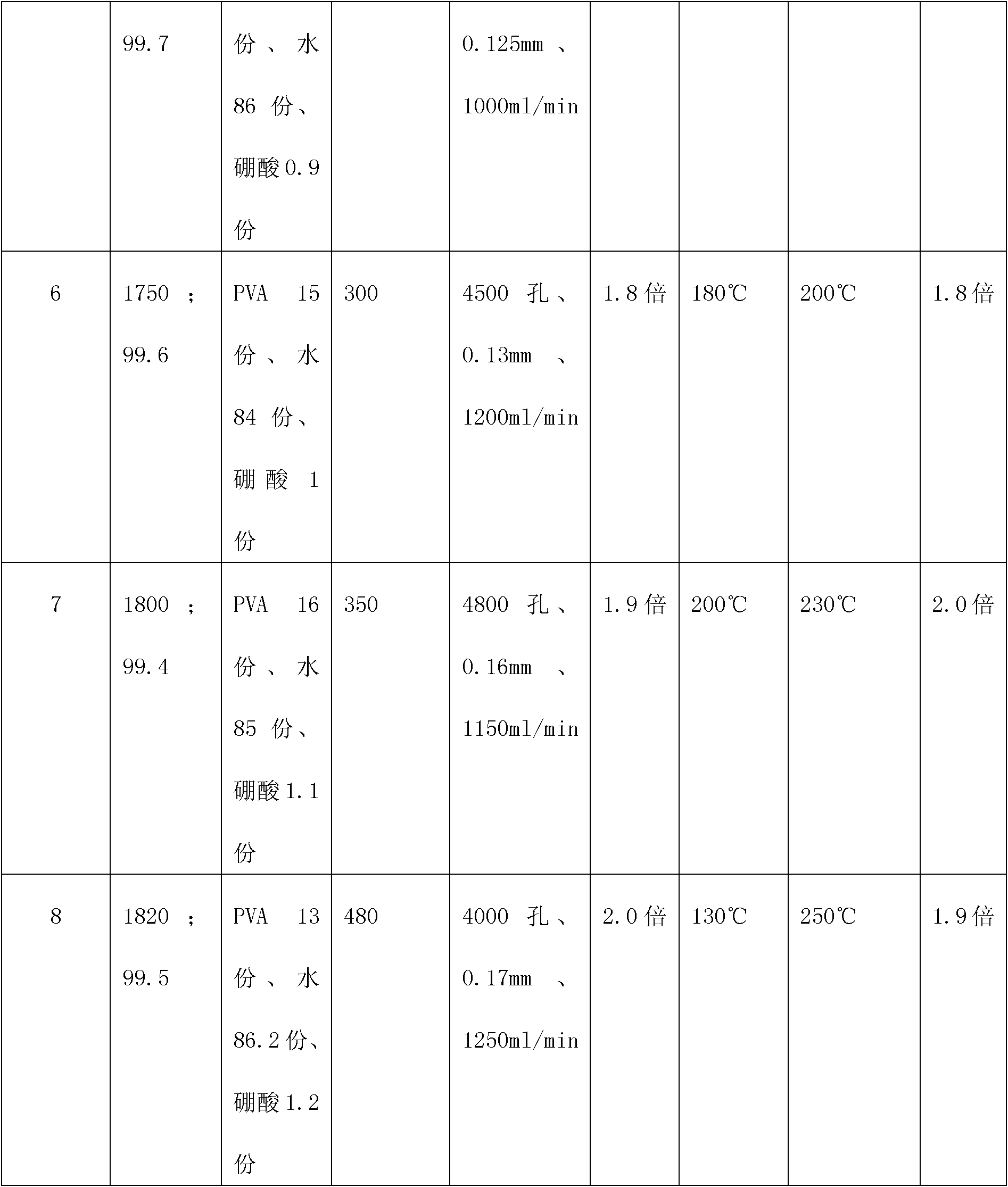

[0034] Embodiments 2-8: carried out according to the following process parameters, and others are the same as in Embodiment 1. The following PVA fiber has a linear density of 6.0-10.0dtex, a strength of 11.0-14.0cN / dtex, a modulus of 270-320cN / dtex, and an elongation of 7.0-9.0%. Its uniformity is very good by visual inspection, and it is very suitable for application in the field of bridge and tunnel construction.

[0035]

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com