Method for directly extracting tea saponin from tea seeds

A technology of tea saponin and tea seeds, which is applied in the field of deep processing of agricultural and forestry by-products, can solve the problems that the quality of tea saponin products cannot meet the market requirements, affect the yield of tea saponin active products, complex processing, etc., and achieve shortened production The effect of cycle, good quality and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

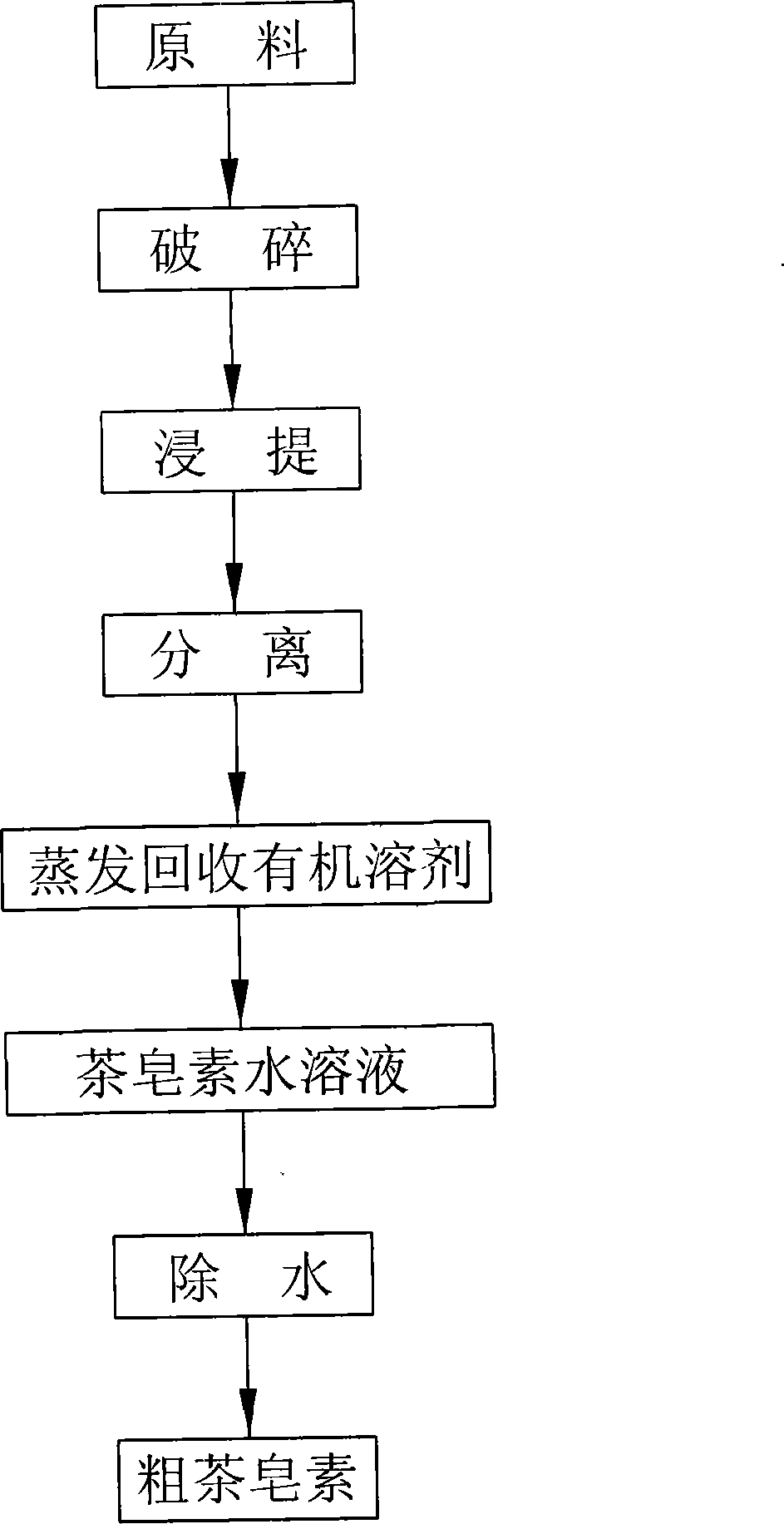

Image

Examples

Embodiment 1

[0014] Weigh 100 grams of Daguo safflower camellia seed kernel, crush it through 80 meshes by wet method, then add water and ethanol to make the ethanol concentration reach 80%, the volume of ethanol solution is 5 times of the weight of camellia oleifera seed, then stir evenly, and heat at 70°C Extract for 2 hours, centrifuge the ethanol solution, repeat the extraction twice and wash the residue, combine the extracts, recover the ethanol and dry the tea saponin aqueous solution to obtain crude tea saponin.

Embodiment 2

[0016] Weigh 100 grams of Daguo safflower camellia seed kernel, crush it through 80 meshes by wet method, then add water and ethanol to make the ethanol concentration reach 85%, the volume of ethanol solution is 7 times of the weight of camellia oleifera seed, then stir evenly, and heat at 70°C Extract for 2 hours, centrifuge the ethanol solution, repeat the extraction twice and wash the residue, combine the extracts, recover the ethanol and dry the tea saponin aqueous solution to obtain crude tea saponin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com