Laundering-durable flame-retarding finishing agent for fabrics

A flame-retardant finishing agent and washing-resistant technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problem of high cost of flame-retardant fibers, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

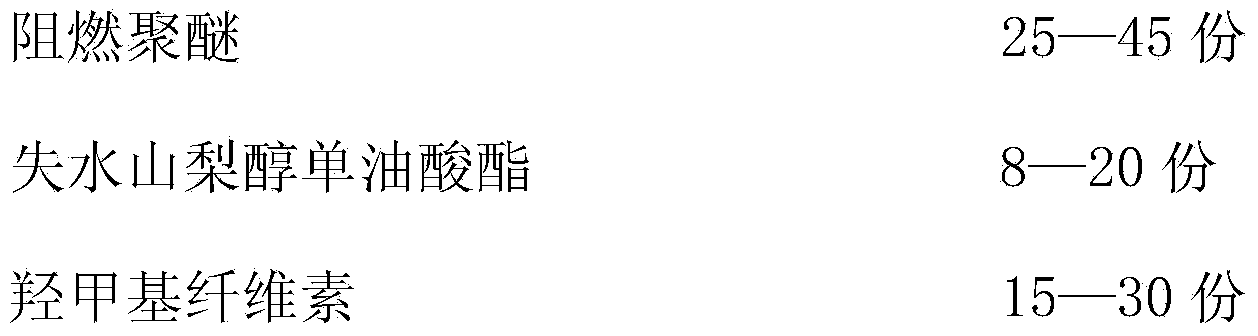

[0015] In this embodiment, the flame retardant finishing agent consists of the following components by weight percentage:

[0016]

[0017]

[0018] Among them, the flame-retardant polyether is a hydroxyl-terminated polyether with an average molecular weight of 3000g / mol

[0019] The preparation method of the above-mentioned flame retardant finishing agent is as follows: first, sorbitan monooleate and maleopimaric acid are added to deionized water, after stirring at a low speed (100r / min), adding flame retardant polyether, Hydroxymethyl cellulose, tris(2,3-dibromo)propyl borate, ammonium dihydrogen phosphate, stir evenly at low speed (120r / min), and finally add guar gum and stir evenly at high speed (1000r / min) to obtain resistance Burning agent.

Embodiment 2

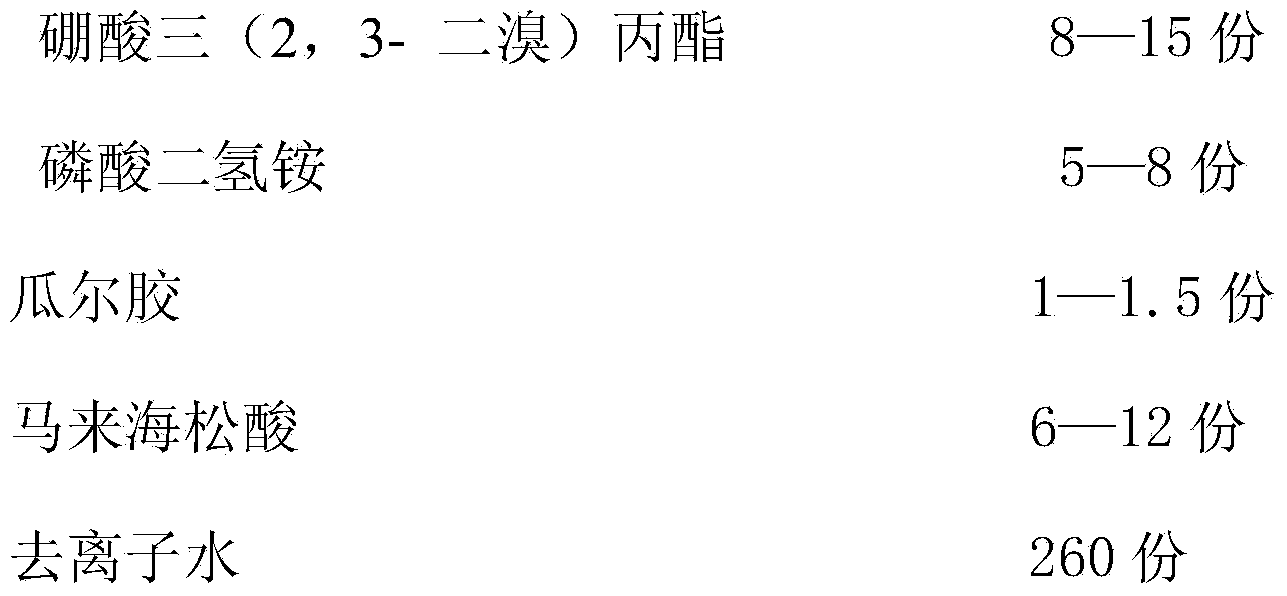

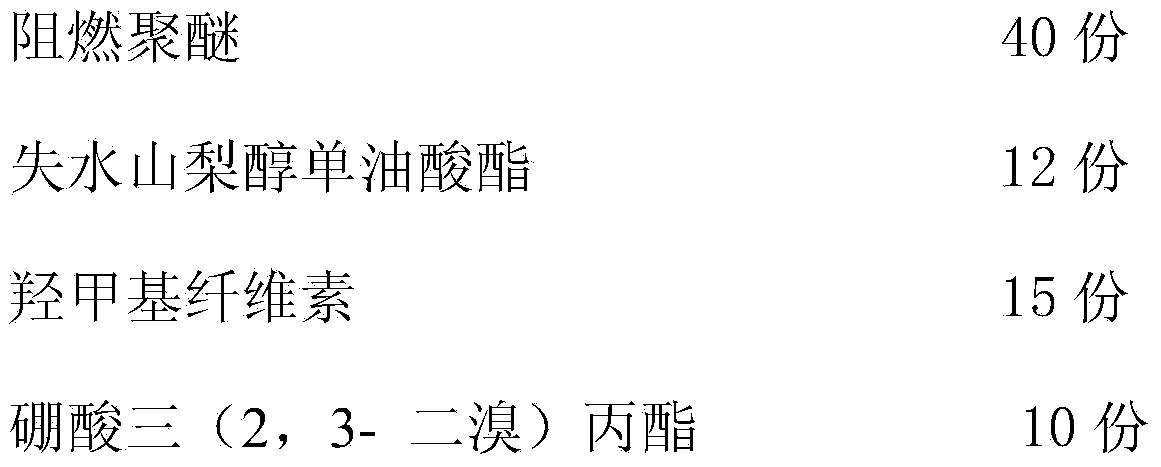

[0021] In this embodiment, the flame retardant finishing agent consists of the following components by weight percentage:

[0022]

[0023] Among them, the flame-retardant polyether is a hydroxyl-terminated polyether with an average molecular weight of 1500g / mol

[0024] The preparation method of the above-mentioned flame retardant finishing agent is as follows: first, sorbitan monooleate and maleopimaric acid are added to deionized water, after stirring at a low speed (130r / min), adding flame retardant polyether, Hydroxymethyl cellulose, tris(2,3-dibromo)propyl borate, ammonium dihydrogen phosphate, stir evenly at low speed (150r / min), finally add guar gum and stir evenly at high speed (1050r / min) to obtain resistance Burning agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com