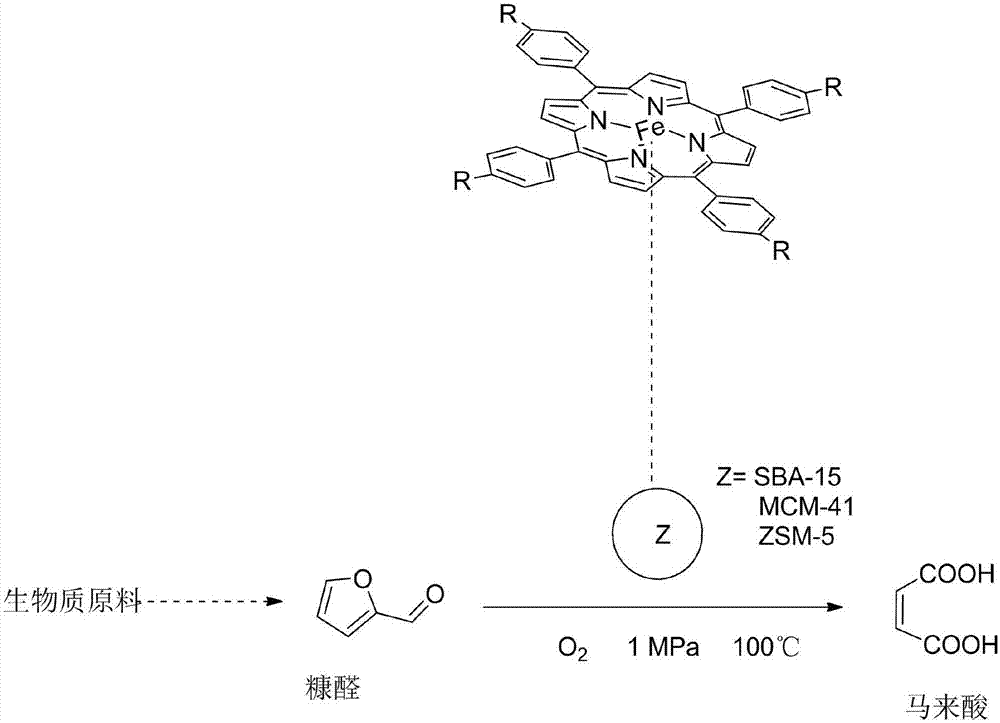

Solid-supported metalloporphyrin catalyst and application thereof in preparation of maleic acid

A technology of metalloporphyrins and catalysts, applied in the field of immobilized metalloporphyrin catalysts and its preparation of maleic acid, can solve the problem of insufficient yield and selectivity of maleic acid, insufficient mild reaction conditions, and long reaction time and other problems, to achieve good catalytic effect, mild reaction conditions, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

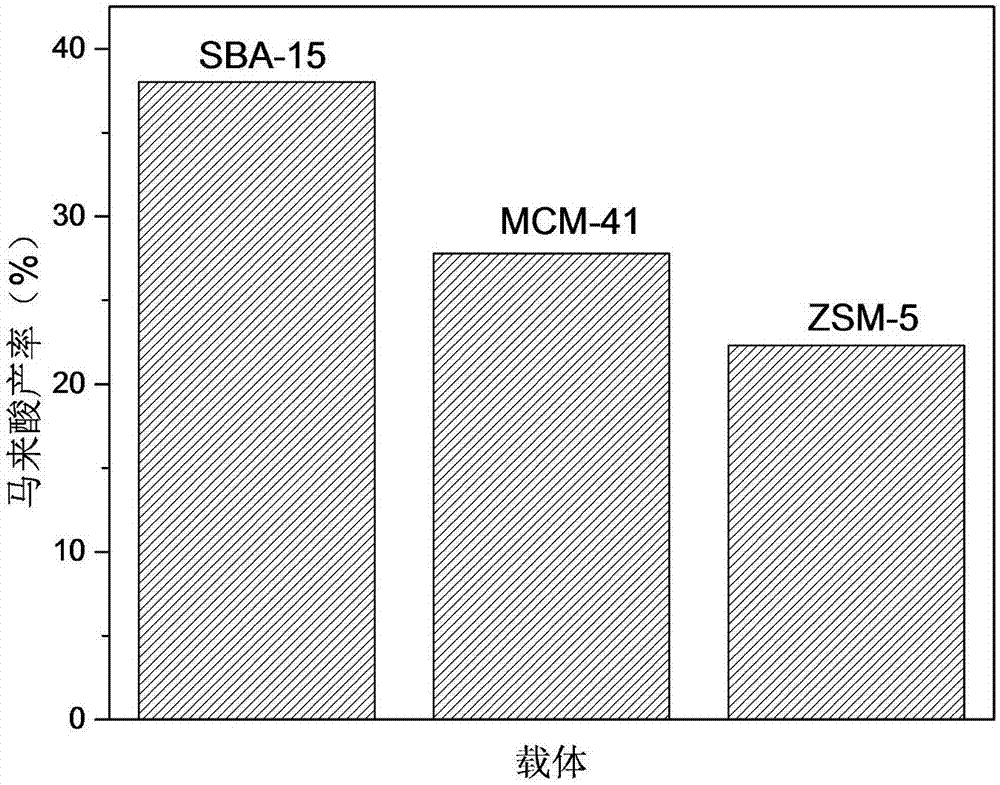

[0046] (1) Weigh 50 mg of the solid-supported metalloporphyrin catalyst FeT(p-R)PP / SBA-15 (wherein R is -Br) in a polytetrafluoroethylene lining, and add 4 mL of deionized water;

[0047] (2) The carrier SBA-15 in step (1) is replaced by MCM-41, ZSM-5;

[0048] (3) Weigh 0.282g furfural into the reaction system of step (1) and step (2), put the polytetrafluoroethylene lining into the stainless steel reaction kettle, heat to 90°C under magnetic stirring, feed oxygen, apply React with a reaction pressure of 1MPa for 6 hours. After the reaction, close the valve of the oxygen cylinder. After the reaction kettle is cooled to room temperature, slowly release the gas in it;

[0049] (4) Pipette 50 μL of the reaction solution in step (3) with a pipette gun, make the volume to 5 mL with deionized water, and measure the yield of maleic acid with a high-performance liquid chromatograph.

[0050] After measurement, the result is as figure 2 As shown, the catalysts prepared with SBA-15,...

Embodiment 2

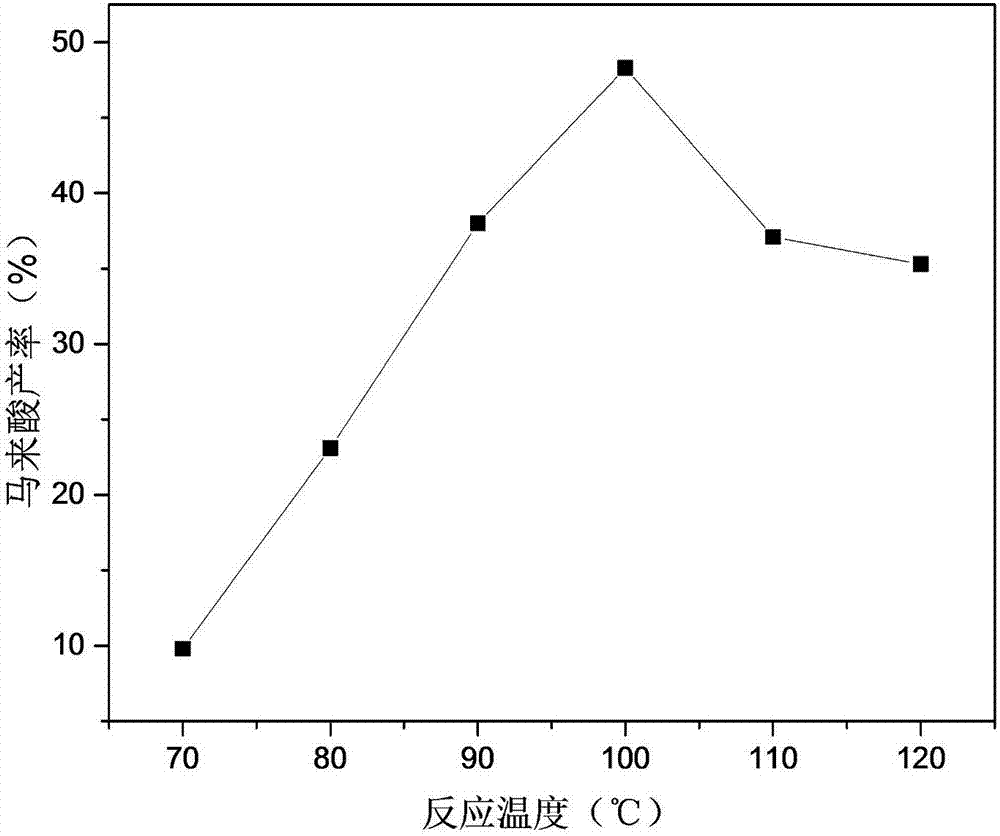

[0061] (1) Weigh 50 mg of the solid-supported metalloporphyrin catalyst FeT(p-R)PP / SBA-15 (wherein R is -Br) in a polytetrafluoroethylene lining, and add 4 mL of deionized water;

[0062] (2) Weigh 0.282g furfural into the reaction system of step (1), put the polytetrafluoroethylene lining into the stainless steel reaction kettle, heat to 70-120°C under magnetic stirring, feed oxygen, and apply 1MPa reaction Pressure reaction for 6 hours, close the valve of the oxygen cylinder after the reaction, and slowly release the gas in the reaction kettle after it is cooled to room temperature;

[0063] (3) Take out 50 μL of the reaction solution in step (2) with a pipette gun, make the volume to 5 mL with deionized water, and measure the yield of maleic acid with a high-performance liquid chromatograph.

[0064] After measurement, the result is as image 3 Shown, when reaction temperature is 70 ℃, 80 ℃, 90 ℃, 100 ℃, 110 ℃, when 120 ℃, the productive rate of maleic acid is respectively...

Embodiment 3

[0066] (1) Weigh 50 mg of the solid-supported metalloporphyrin catalyst FeT(p-R)PP / SBA-15 (wherein R is -Br) in a polytetrafluoroethylene lining, and add 4 mL of deionized water;

[0067] (2) Weigh 0.282g of furfural into the reaction system of step (1), put the polytetrafluoroethylene lining into the stainless steel reaction kettle, heat to 100°C under magnetic stirring, feed oxygen, and apply a reaction pressure of 1MPa to react 3-8h, close the valve of the oxygen cylinder after the reaction is over, and slowly release the gas in the reactor after it cools down to room temperature;

[0068] (3) Take out 50 μL of the reaction solution in step (2) with a pipette gun, make the volume to 5 mL with deionized water, and measure the yield of maleic acid with a high-performance liquid chromatograph.

[0069] After measurement, the result is as Figure 4 As shown, when the reaction time is respectively 3h, 4h, 5h, 6h, 7h, 8h, the yield of maleic acid is respectively 35.7%, 41.6%, 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com