ZSM-5 mesoporous molecular sieve catalyst for preparing propylene from methanol and preparation thereof

A mesoporous molecular sieve, methanol-to-propylene technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low propylene/ethylene mass ratio, low propylene selectivity, molecular sieve thermal stability and water poor thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0014] Molar ratio of silicon to aluminum to SiO 2 / Al 2 o 3 40 mesoporous ZSM-5 molecular sieve powder (wherein the mesopore / micropore pore volume ratio is 2.0) and 0%, 10%, 30%, 70% binder SiO in weight percentage 2 Mixed, extruded and calcined at 600°C for 8 hours. 0.1, 1.0, 3.0, 5.0 mol / L hydrochloric acid, nitric acid solution at a temperature of 20, 40, 70, 90°C with a volume liquid-solid ratio of 10 or at a temperature of 70°C with a volume liquid-solid ratio of 0.1, Exchange in 0.5, 2.0, 3.0 mol / L ammonium nitrate, ammonium sulfate or ammonium chloride solution for 1, 3, 5, 8 hours. Then at a temperature of 600°C and a space velocity of 0.2 hours -1 Treat with steam for 8 hours, soak with oxalic acid, citric acid or maleic acid solution at 70°C for 2, 3, and 5 hours at a volume liquid-solid ratio of 10, and roast at 600°C to obtain the desired modified molecular sieve catalyst.

Embodiment 9

[0016] The modified molecular sieve catalysts prepared in Examples 1 to 8 were used in the reaction of methanol conversion to propylene, using methanol as raw material, the pre-reaction temperature was 400°C, the reaction temperature was 500°C, the reaction pressure was 0.04MPa, and the space velocity of methanol was 4 Hour -1 , the reaction raw materials pass through the Al 2 o 3 The catalyst bed and the modified ZSM-5 molecular sieve bed react to generate propylene. The reaction results are listed in Table 1.

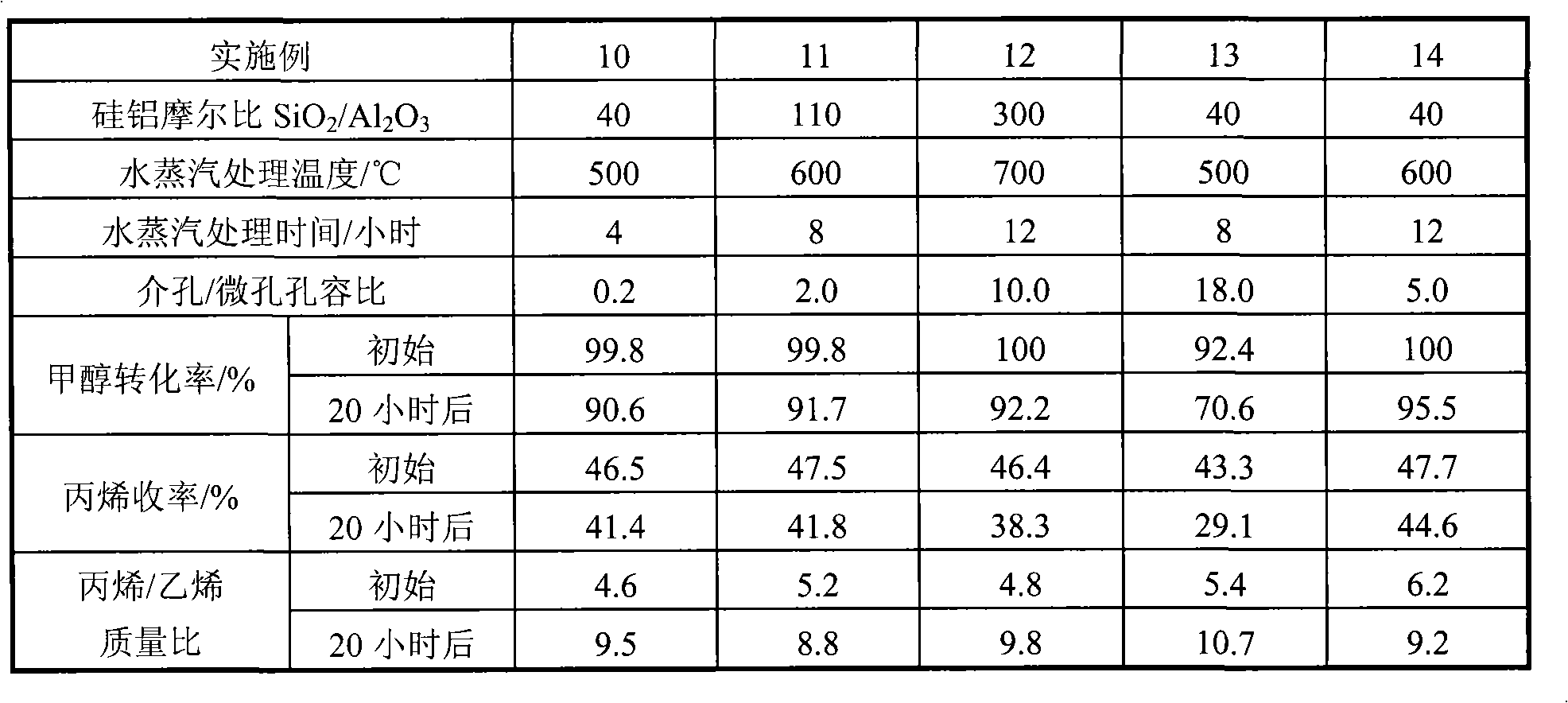

Embodiment 10~14

[0018] SiAl to SiO 2 / Al 2 o 3 40, 110, 300, ZSM-5 mesoporous molecular sieve raw powder with mesopore / micropore volume ratio of 0.2, 2.0, 5.0, 10.0, 18.0 and 30% binder SiO in weight percentage 2 Mixed, extruded and calcined at 600°C for 8 hours. Exchange in a 0.5 mol / L hydrochloric acid solution with a volume liquid-solid ratio of 10 at a temperature of 70° C. for 5 hours. Then at a temperature of 500, 600, 700°C and a space velocity of 0.2 hours -1 Under steam treatment for 4, 8, 12 hours. The desired modified molecular sieve catalyst was obtained by rinsing with oxalic acid at a volume-to-solid ratio of 10 at 90° C. for 5 hours, and roasting at 600° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com