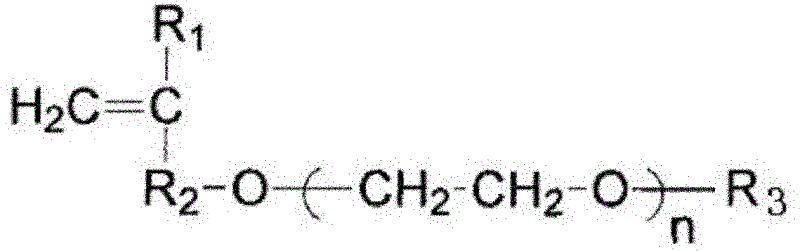

Allyl polyglycol ether polycarboxylic acid water reducer and synthetic method thereof

A technology based on polyethylene glycol ether and polycarboxylate, which is applied in the field of polycarboxylate water reducer for concrete and its synthesis, can solve the problems of low conversion rate of maleic anhydride and precipitation of maleate, and achieve the goal of maintaining Good slump performance, improved polymerization activity, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

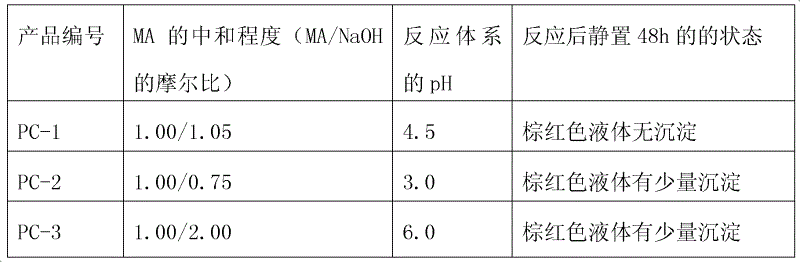

[0038] Add the maleic anhydride of 2000g allyl polyglycol ether (molecular weight is 2000), the maleic anhydride of 196g, the deionized water of 2000g in the reactor that is equipped with stirrer, thermometer, dropping device, reflux cooler, heat to complete Dissolve, adjust the pH of the reaction system to 4.5 with 210 g of 40% sodium hydroxide solution, then add 1.5 g of ferrous ammonium sulfate, and heat the system to 100°C. With the mixed solution of 36g acrylic acid, 20g 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 2000g deionized water, after adjusting the pH of the mixed solution to 4.5, and 108g concentration of 35% hydrogen peroxide were added dropwise at the same time Into the reactor, the dropwise addition time is 5h. After the dropwise addition, keep warm for 2h, then naturally cool to 30°C, adjust the pH to 6 with 30% sodium hydroxide solution, and adjust the solid content of the product to 40%. Record the sample as PC-1.

Embodiment 2

[0040] Add the maleic anhydride of 2000g allyl polyglycol ether (molecular weight is 2000), the maleic anhydride of 196g, the deionized water of 2000g in the reactor that is equipped with stirrer, thermometer, dropping device, reflux cooler, heat to complete Dissolve, adjust the pH value of the reaction system to 3.0 with 150 g of sodium hydroxide solution with a mass concentration of 40%, then add 1.5 g of ferrous ammonium sulfate, and heat the system to 100°C. With the mixed solution of 36g acrylic acid, 20g 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 2000g deionized water, after adjusting the pH of the mixed solution to be 3.0, it is 35% hydrogen peroxide with 108g concentration to be added dropwise to In the reactor, the dropwise addition time is 5h. After the dropwise addition, keep warm for 2h, then naturally cool to 30° C., adjust the pH to 6 with 30% sodium hydroxide solution, and adjust the solid content of the product to 40%. Record the sample as PC-2.

Embodiment 3

[0042] Add the maleic anhydride of 2000g allyl polyglycol ether (molecular weight is 2000), the maleic anhydride of 196g, the deionized water of 2000g in the reactor that is equipped with stirrer, thermometer, dropping device, reflux cooler, heat to complete Dissolve, adjust the pH of the reaction system to 6.0 with 400 g of 40% sodium hydroxide solution, then add 1.5 g of ferrous ammonium sulfate, and heat the system to 100°C. With the mixed solution of 36g acrylic acid, 20g 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 2000g deionized water, after adjusting the pH of the mixed solution to 6.0, and 108g concentration of 35% hydrogen peroxide were added dropwise at the same time Into the reactor, the dropwise addition time is 5h. After the dropwise addition, keep warm for 2h, then naturally cool to 30°C, adjust the pH to 6 with 30% sodium hydroxide solution, and adjust the solid content of the product to 40%. Record the sample as PC-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com