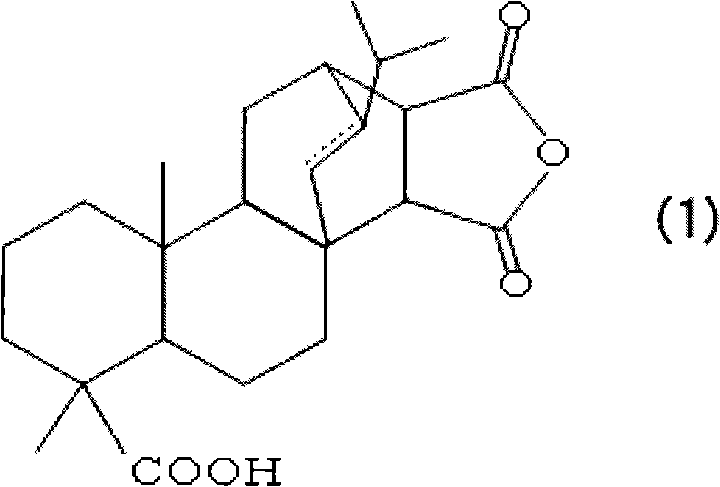

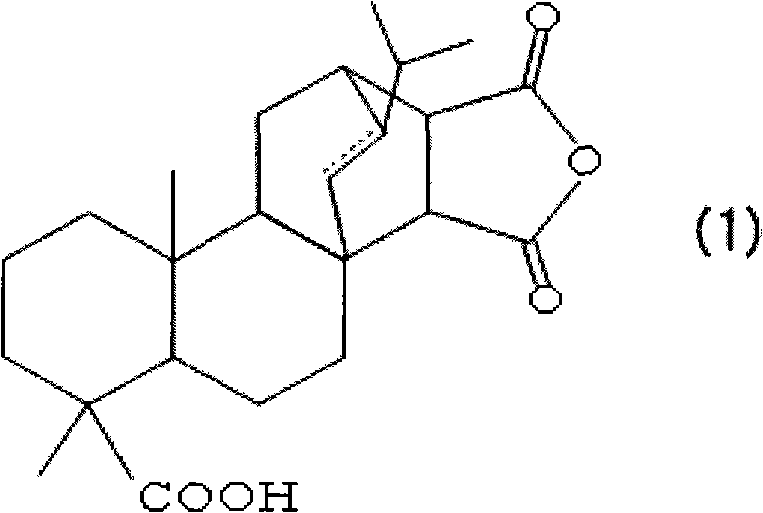

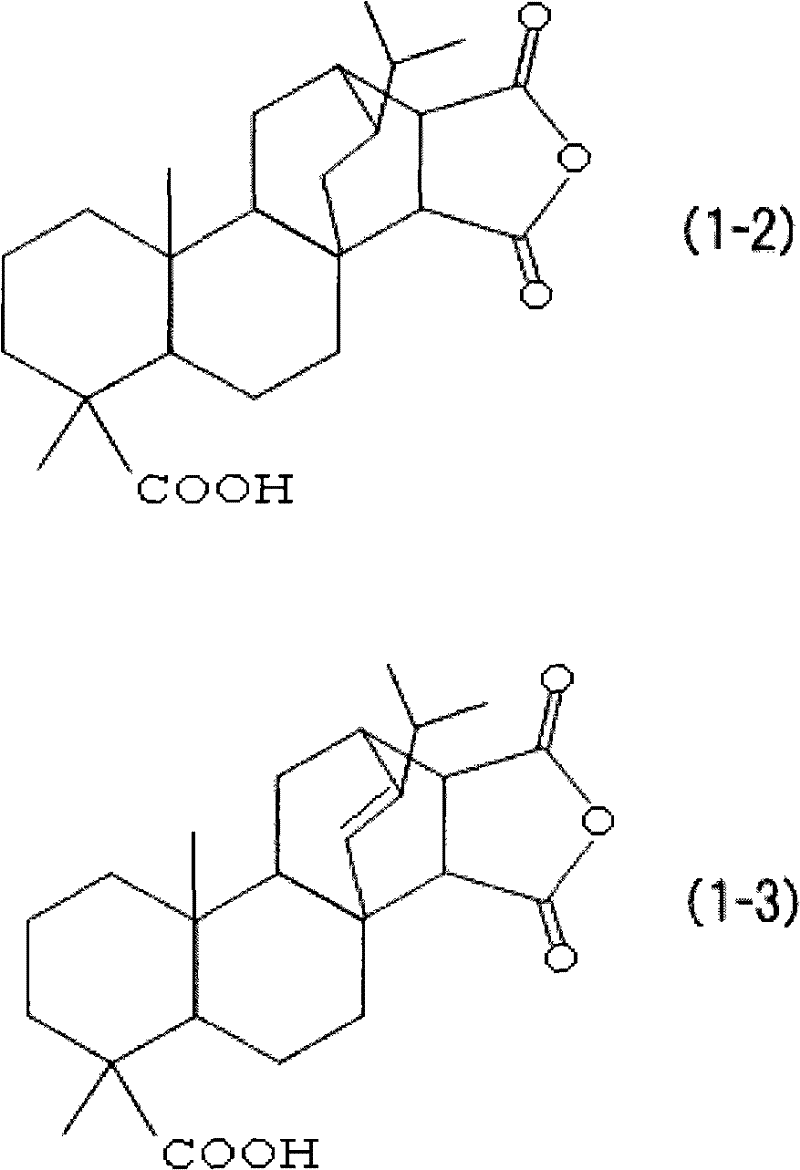

Rosin-based flux for soldering and solder paste

A rosin and flux technology, applied in rosin coatings, welding/cutting media/materials, welding media, etc., can solve the problems of complicated manufacturing process, contamination of the surface of the mounting substrate, and large generation, and achieves good visibility and color tone. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated more concretely, this invention is not limited to these Examples.

[0056] In addition, in each preparation example, "melt viscosity" represents the value obtained by a commercially available B8M type viscometer (product name "VISCOMETER", manufactured by TOKIMEC Co., Ltd., Robot No. HM-1), "Content of maleopimaric acid anhydrides" and "content of low molecular weight components" indicate a commercially available gel permeation chromatography measuring device (product name "High Speed GPC System HLC-8220", manufactured by Tosoh Corporation, column name " TSK-GEL G1000HXL", manufactured by Tosoh Corporation, developing agent tetrahydrofuran), and "Content of dehydroabietic acid" indicates values obtained from a commercially available gas chromatograph (product name "GC7890", manufactured by Agilent Corporation) The calculated value of .

[0057]

preparation example 1

[0059] Step (1): Refining

[0060] Unrefined gum rosin (measured acid value 171mgKOH / g, unit carboxyl molar concentration 3.2×10 -3 mol / g, softening temperature 74°C, Gardner chroma 6, made in China) was added to a vacuum distillation vessel, and distilled under a reduced pressure of 0.4kPa under a nitrogen seal to obtain refined rosin (actually measured acid value 177, softened Temperature 80°C, Gardner color 3).

[0061] Step (2): Diels-Alder reaction

[0062] Next, 700 g of the purified rosin and 154 g of maleic anhydride were added to another vacuum distillation vessel, and reacted at 220° C. for 4 hours while stirring with a nitrogen stream, and then, the unreacted rosin was removed under a reduced pressure of 4 kPa. As a result, rosin derivatives (theoretical acid value 144mgKOH / g, unit carboxyl molar concentration 2.7×10 -3 mol / g, softening temperature 121°C, Gardner color 8).

[0063] Step (3): Hydrogenation reaction

[0064] Next, 500 g of the rosin derivative an...

preparation example 2

[0068] A hydrogenated rosin derivative (A-2) (hereinafter referred to as (A-2) component) was obtained in the same manner except that 154 g of maleic anhydride in the step (2) of Production Example 1 was changed to 77 g. Table 1 shows physical properties and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com