Pimaric acid modified phenolic aldehyde foaming resin

A foamed resin and phenolic resin technology, which is applied in the field of pimaric acid-modified phenolic foamed resin, can solve the problem of no pimaric acid-type resin acid considering industrial utilization alone, and achieves improved toughness, improved carbon residue rate and water absorption, The effect of reducing the proportion of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

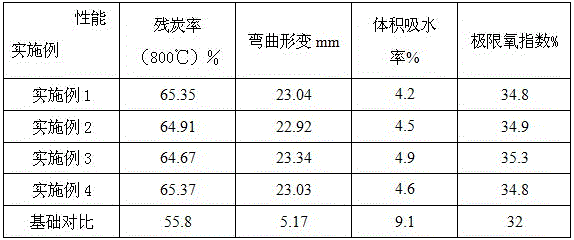

Examples

Embodiment 1

[0026] Add phenol to paraformaldehyde in a mass ratio of 100:55 into the reactor, mix well, add 1 mass part of sodium hydroxide, and react in a constant temperature water bath at 90°C for 90 minutes to obtain a expandable phenolic resin. Add phenolic resin, pimaric acid, and aluminum oxide into a three-necked flask at a mass ratio of 100:80:3, stir well and heat up to 140°C, continue stirring for three hours, then add 3 mass parts of Tween -80 and 8 parts by mass of n-pentane, after uniform mechanical stirring, to obtain the phenolic resin modified by pimaric acid. Preheat the oven at 60°C for 30 minutes, add 12 parts by mass of toluenesulfonic acid to the prepared modified phenolic resin and stir evenly, then put the prepared modified phenolic resin into the oven for foaming 45min~60min. After cooling, demould to obtain pimaric acid modified phenolic foam.

Embodiment 2

[0028] Add phenol to paraformaldehyde in a mass ratio of 100:55 into the reactor, mix well, add 1 mass part of sodium hydroxide, and react in a constant temperature water bath at 90°C for 90 minutes to obtain a expandable phenolic resin. Add phenolic resin, pimaric acid, and aluminum oxide into a three-necked flask at a mass ratio of 100:85:3, stir well and heat up to 140°C, continue stirring for three hours, then add 3 mass parts of Tween -80 and 8 parts by mass of n-pentane, after uniform mechanical stirring, to obtain the phenolic resin modified by pimaric acid. Preheat the oven at 60°C for 30 minutes, add 12 parts by mass of toluenesulfonic acid to the prepared modified phenolic resin and stir evenly, then put the prepared modified phenolic resin into the oven for foaming 45min~60min. After cooling, demould to obtain pimaric acid modified phenolic foam.

Embodiment 3

[0030] Add phenol to paraformaldehyde in a mass ratio of 100:55 into the reactor, mix well, add 1 mass part of sodium hydroxide, and react in a constant temperature water bath at 90°C for 90 minutes to obtain a expandable phenolic resin. Add phenolic resin, pimaric acid, and aluminum oxide into a three-necked flask at a mass ratio of 100:90:4, stir well and heat up to 140°C, continue stirring for three hours, then add 3 mass parts of Tween -80 and 8 parts by mass of n-pentane, after uniform mechanical stirring, to obtain the phenolic resin modified by pimaric acid. Preheat the oven at 60°C for 30 minutes, add 12 parts by mass of toluenesulfonic acid to the prepared modified phenolic resin and stir evenly, then put the prepared modified phenolic resin into the oven for foaming 45min~60min. After cooling, demould to obtain pimaric acid modified phenolic foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com