Preparation and separation method of high-purity p-acrylic pimaric acid

A technology of acrylopimaric acid and a separation method, which is applied in the separation/purification of carboxylic acid compounds, preparation of carboxylate, preparation of organic compounds, etc., can solve the problems of complicated operation, product separation and characterization, and high cost, and achieves good repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A method for separating and preparing p-propylenepimaric acid, using rosin and acrylic acid as raw materials, and preparing acrylic acid-modified rosin through Diels-Alder reaction under microwave-assisted conditions. Using acrylic acid-modified rosin or its purified product, acrylic pimaric acid, as raw materials, using benzene and ethyl acetate as developing agents, continuously adding developing agents to a cyclodextrin-modified silica gel chromatography column with a particle size of 0.044-0.075 mm, from Collect p-propylenepimaric acid from the fractionated eluate obtained. The specific column chromatography processing steps are as follows:

[0019] Cyclodextrin-modified silica gel: 1) Weigh 7g of TLC silica gel and put it into a 250mL flask, add 35mL of benzene, 40mL of thionyl chloride, reflux for 10h under stirring, filter after the reaction, and put the product at 90 ℃ into a vacuum drying oven to dry, after drying a white powder. 2) Weigh 9g of hydroxypropyl-...

Embodiment 1

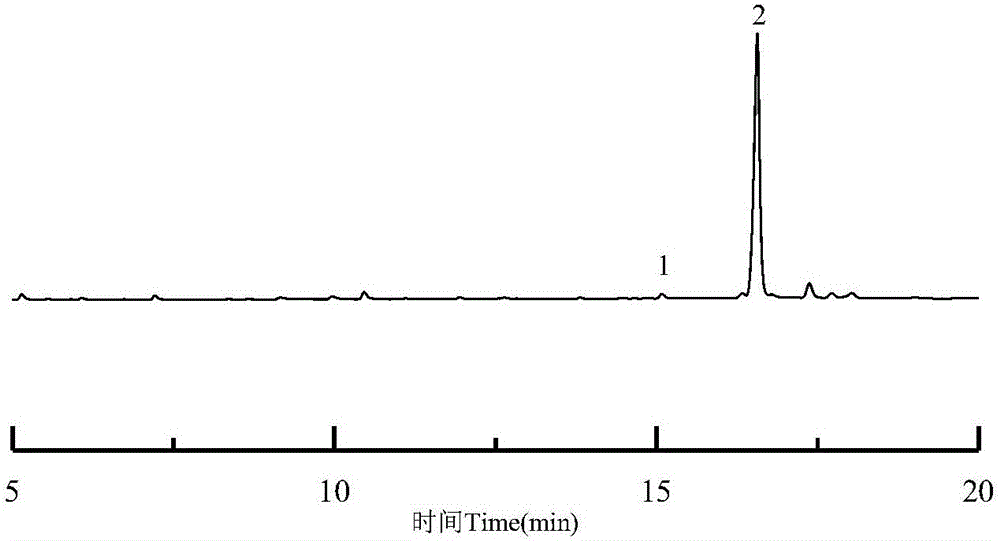

[0025] Add 10g of rosin and 2.4g of acrylic acid into the flask, place it in a microwave reaction workstation, and prepare acrylic acid-modified rosin under the conditions of microwave power 300W, reaction temperature 230°C, and reaction time 90min. Using this acrylic acid-modified rosin as a raw material, using benzene and ethyl acetate as a developer with a volume ratio of 5:1, passing through a 0.044-0.075mm cyclodextrin-modified silica gel column, and concentrating the extract to dryness to obtain p-propylene Pimaric acid. The yield of isolated p-propylenepimaric acid was 35.4%, and the GC content of p-propylenepimaric acid obtained by column chromatography was 85.6%.

Embodiment 2

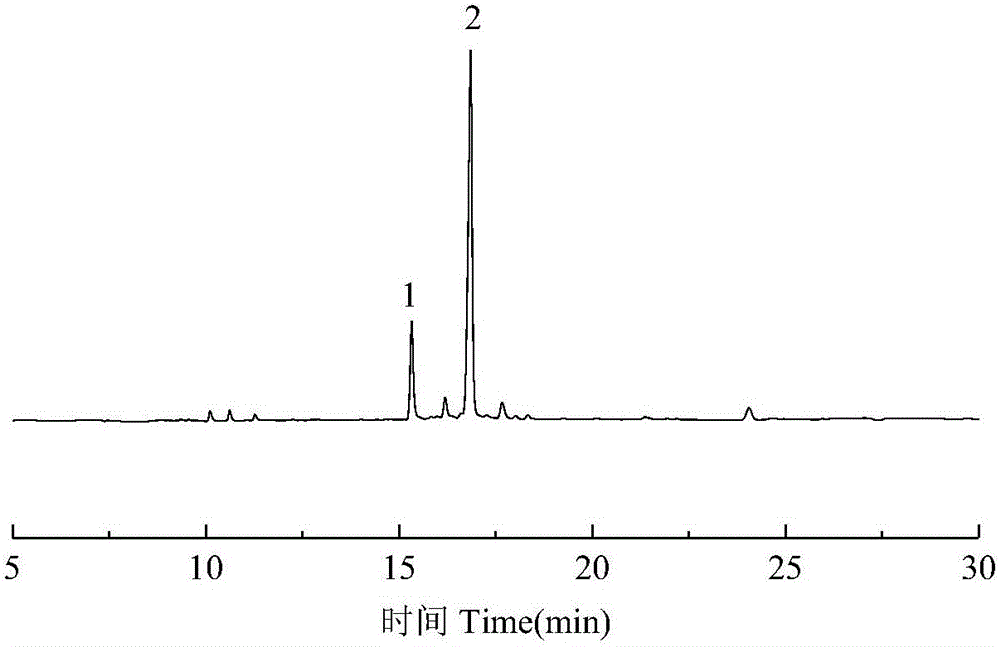

[0027] Add 10g of rosin and 4.8g of acrylic acid into the flask, place it in a microwave reaction workstation, and prepare acrylic acid-modified rosin under the conditions of microwave power 400W, reaction temperature 200°C, and reaction time 110min. Using this acrylic acid-modified rosin as raw material, using benzene and ethyl acetate volume ratio of 8:1 as the developer, passing through a 0.044-0.075mm cyclodextrin-modified silica gel column, and concentrating the extract to dryness to obtain p-propylene Pimaric acid. The yield of p-propylenepimaric acid obtained by separation was 29.7%, and the GC content of p-propylenepimaric acid obtained by column chromatography was 85.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com