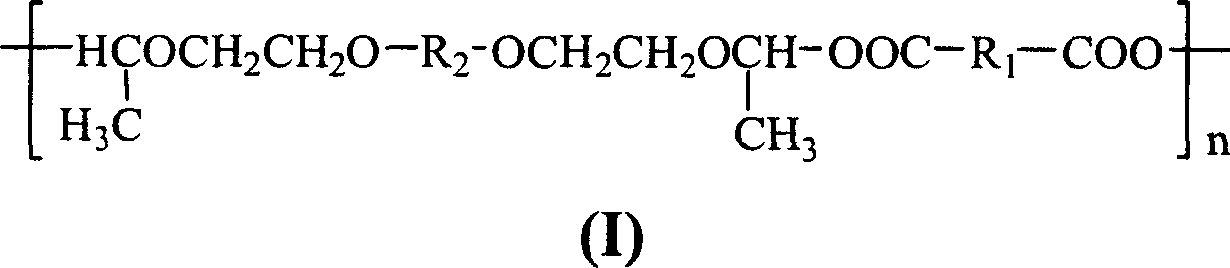

Colophony diacid ester aldehyde acetal polyalcohol, synthesis method and uses of the same

A technology of rosin dibasic acid ester and acetal polymer, which is applied in the fields of instruments, optics, and optomechanical equipment, and can solve problems such as increasing the difficulty of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The present invention is illustrated by the following examples, but these examples do not limit the scope of the invention.

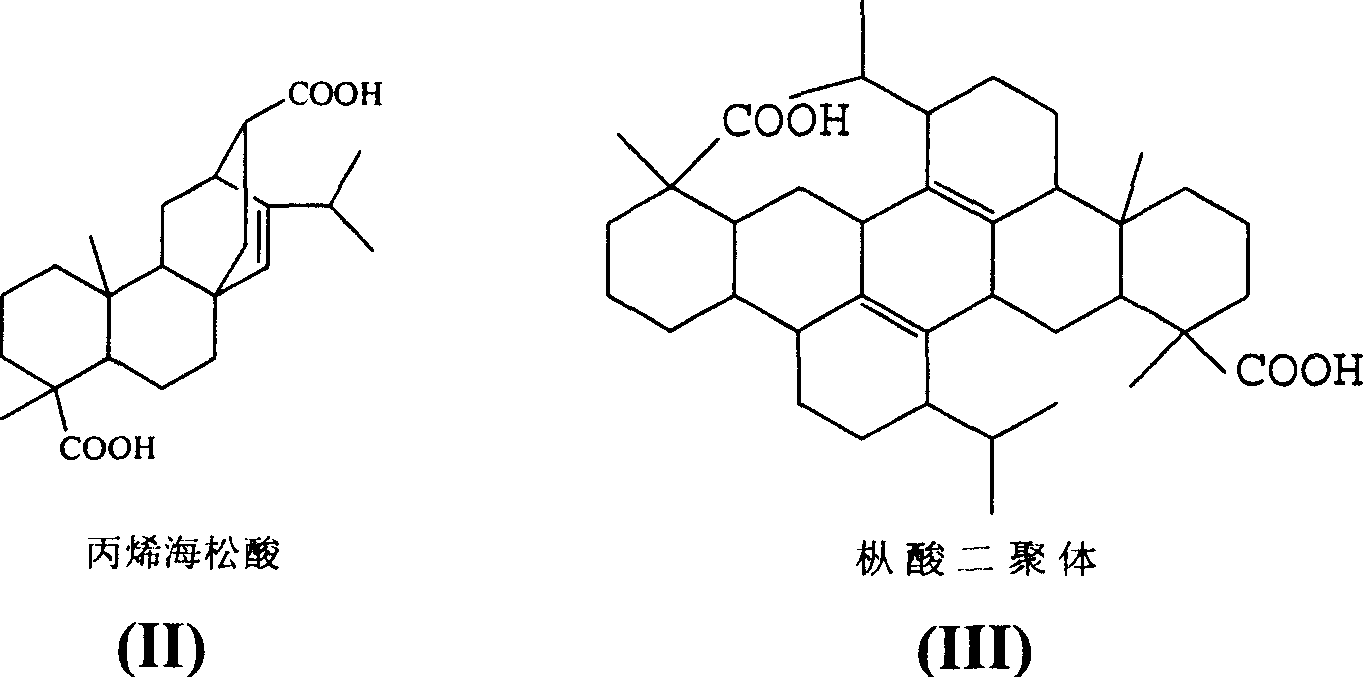

[0038] Reference Example 1 Preparation of Propylene Pimaric Acid

[0039] Take 100g of commercially available super-grade rosin and add it to a 500ml four-necked flask with a stirring and condensing device, add 1g of hydroquinone, heat to 230°C, introduce nitrogen gas (flow rate of 60ml / min), add dropwise 22g of acrylic acid, and keep warm for 3 hours , cooled to room temperature, dissolved in 200ml of acetone, and added dropwise to 600ml of hot water at 80°C, to precipitate solid powder with a yield of 85%. The solid powder was dissolved with 500ml of 4% by weight NaOH aqueous solution, and the resulting solution was added dropwise with 5M hydrochloric acid to pH 7-8 under stirring, and then added dropwise with 1M hydrochloric acid until the pH was 6.5. After the precipitate was filtered off, 1M hydrochloric acid was added dropwise until ther...

Embodiment 2

[0040] Reference Example 2 Preparation of abietic acid dimer

[0041] Add 150 g of commercially available extra-grade rosin, 250 ml of 95% ethanol and 10 ml of concentrated hydrochloric acid into a 500 ml single-necked flask. Heat to reflux for 3 hours, cool to 0°C, let stand for 4 to 5 hours, collect the precipitated solid, wash with distilled water until the washing liquid is neutral, and dry to obtain 75g of abietic acid, wherein the content of abietic acid is close to 95%.

[0042] Add 50g of the abietic acid prepared above into a 500ml three-neck flask, add 60ml of toluene, and stir to dissolve at room temperature. The temperature was controlled at about 40°C, and a mixture of 5ml of concentrated sulfuric acid and 1ml of glacial acetic acid was added dropwise over 1.5 hours, and the reaction was continued for 2.5 hours to complete. Add 200ml of toluene to dilute and let stand for 4 hours to separate the layers. Separate the organic phase, and wash it with 0.5% hot (60...

Embodiment 1

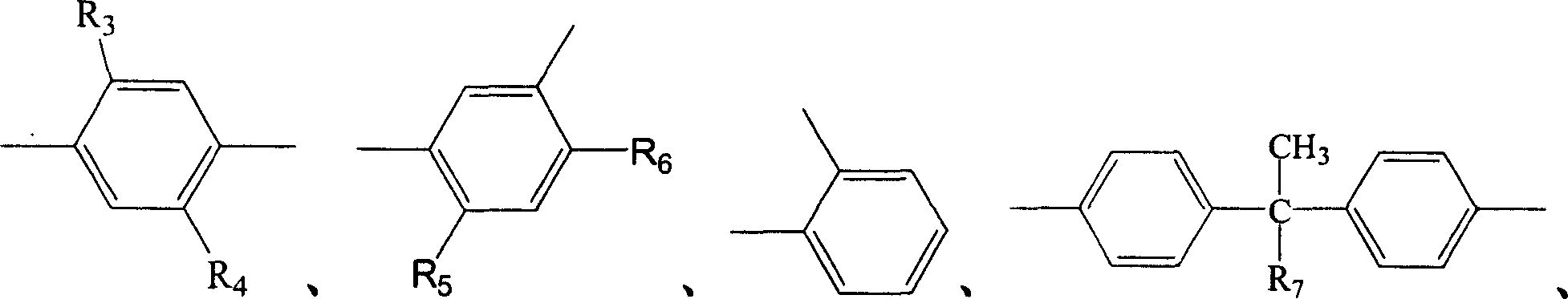

[0043] Example 1 Reaction of propylene pimaric acid with 1,4-divinyloxyethoxybenzene (hydroquinone divinyloxyethyl ether)

[0044] Add 37.4g (0.1mol) of propylene pimaric acid from reference example 1 and 25.1g (0.1mol) of 1,4-divinyloxyethoxy in the 500ml four-necked bottle equipped with mechanical stirring, thermometer and condenser Add 120ml of xylene to benzene (hydroquinone divinyloxyethyl ether), heat and stir to dissolve it, raise the temperature to 120°C, and complete the reaction with stirring for 3 hours.

[0045] Product Determination Infrared Spectrum Visible 3400cm -1 Absorption of nearby carboxylic acids basically disappears, 1690cm -1 Carbonyl absorption of nearby carboxylic acid disappears, 1720cm -1 The carbonyl absorption of the ester group occurs nearby. Indicates that the reaction is complete.

[0046] Example 2 Reaction of Propylene Pimaric Acid with 1,3-Divinyloxyethoxybenzene (Resorcinol Divinyloxyethyl Ether)

[0047] Add 37.4g (0.1mol) of prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com