Patents

Literature

48results about How to "Yield and" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

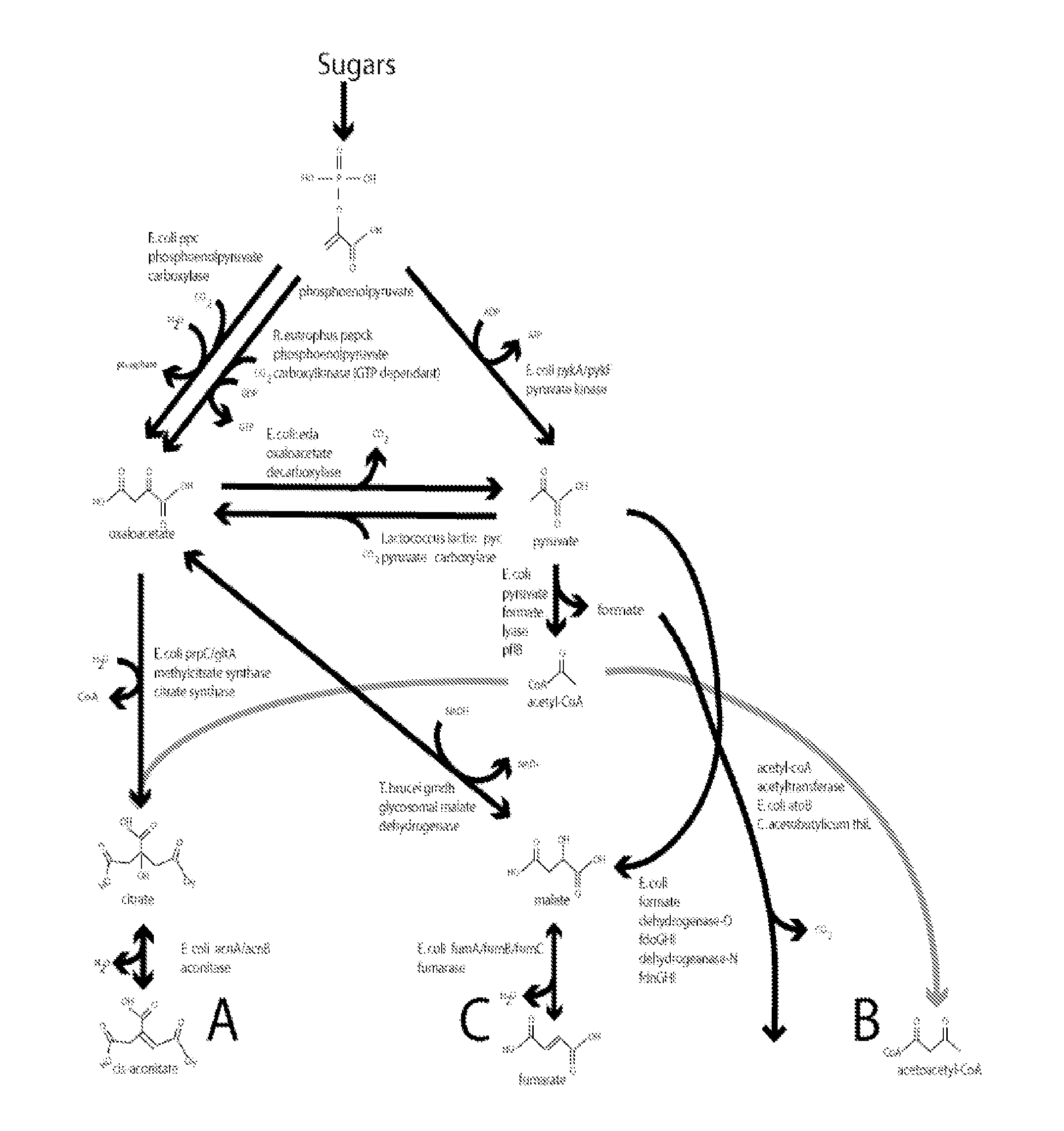

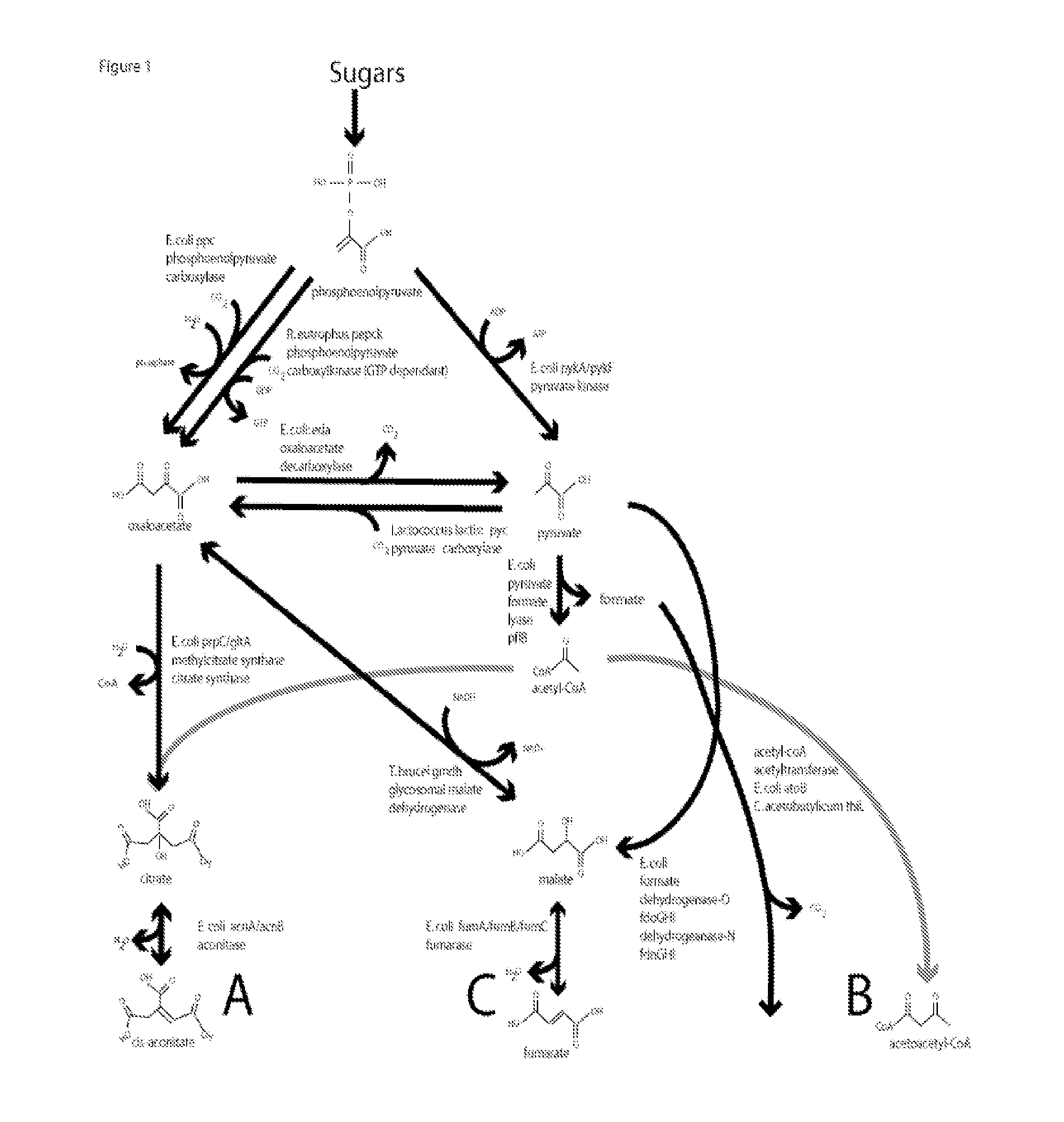

Methods, compositions and systems for biosynthetic bio-production of 1,4-butanediol

InactiveUS20110190513A1Improve toleranceYield andBioreactor/fermenter combinationsBiological substance pretreatments1,4-ButanediolMicroorganism

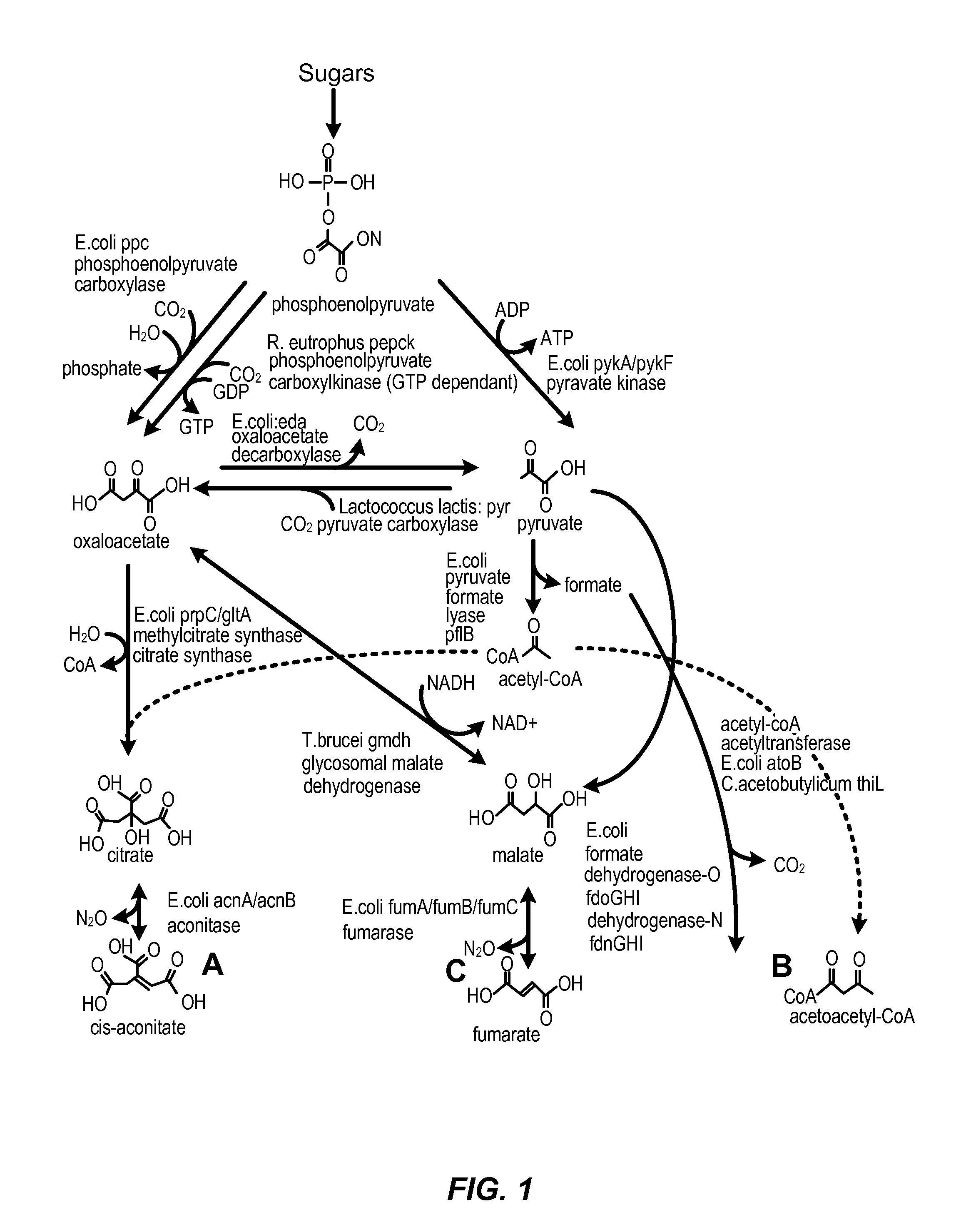

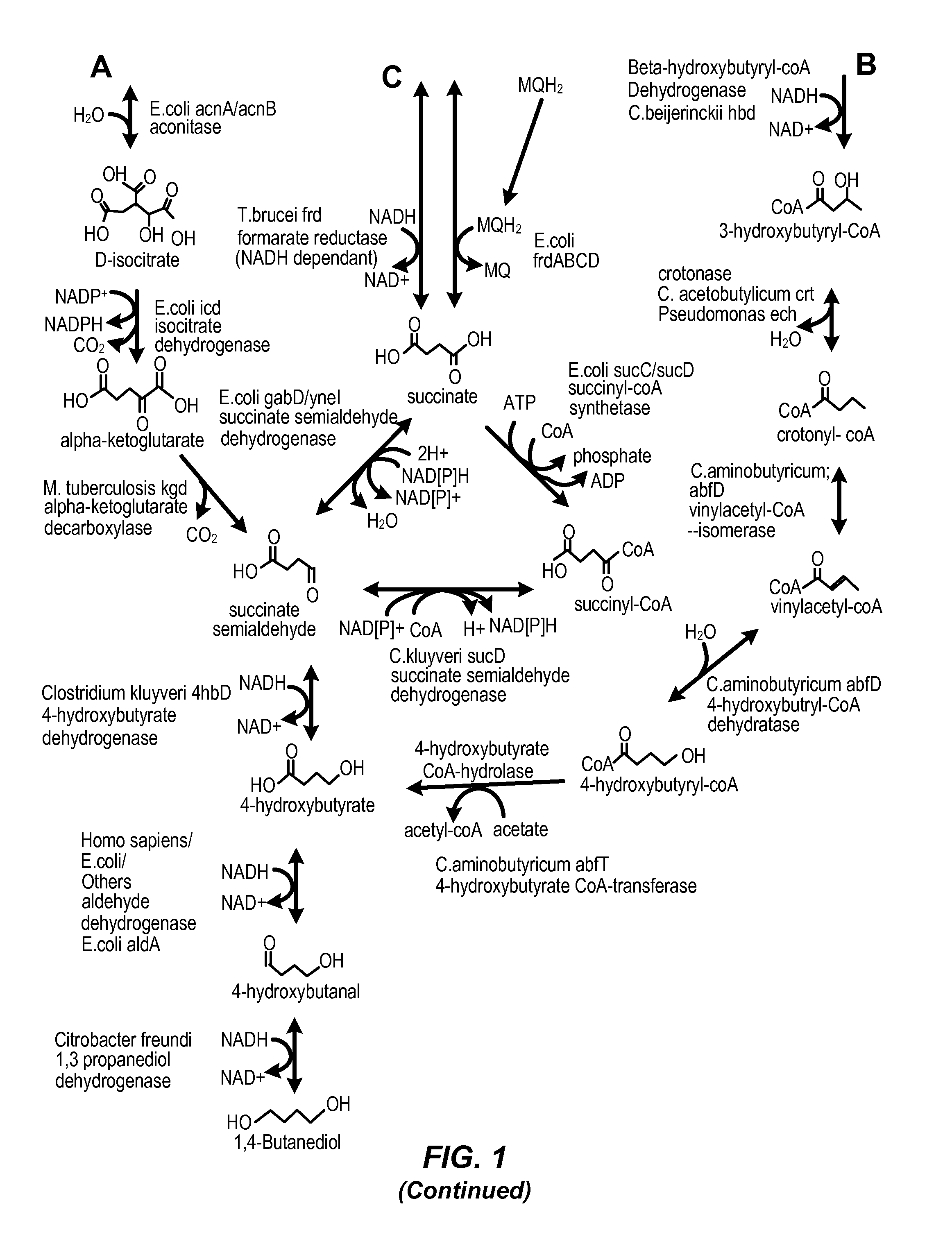

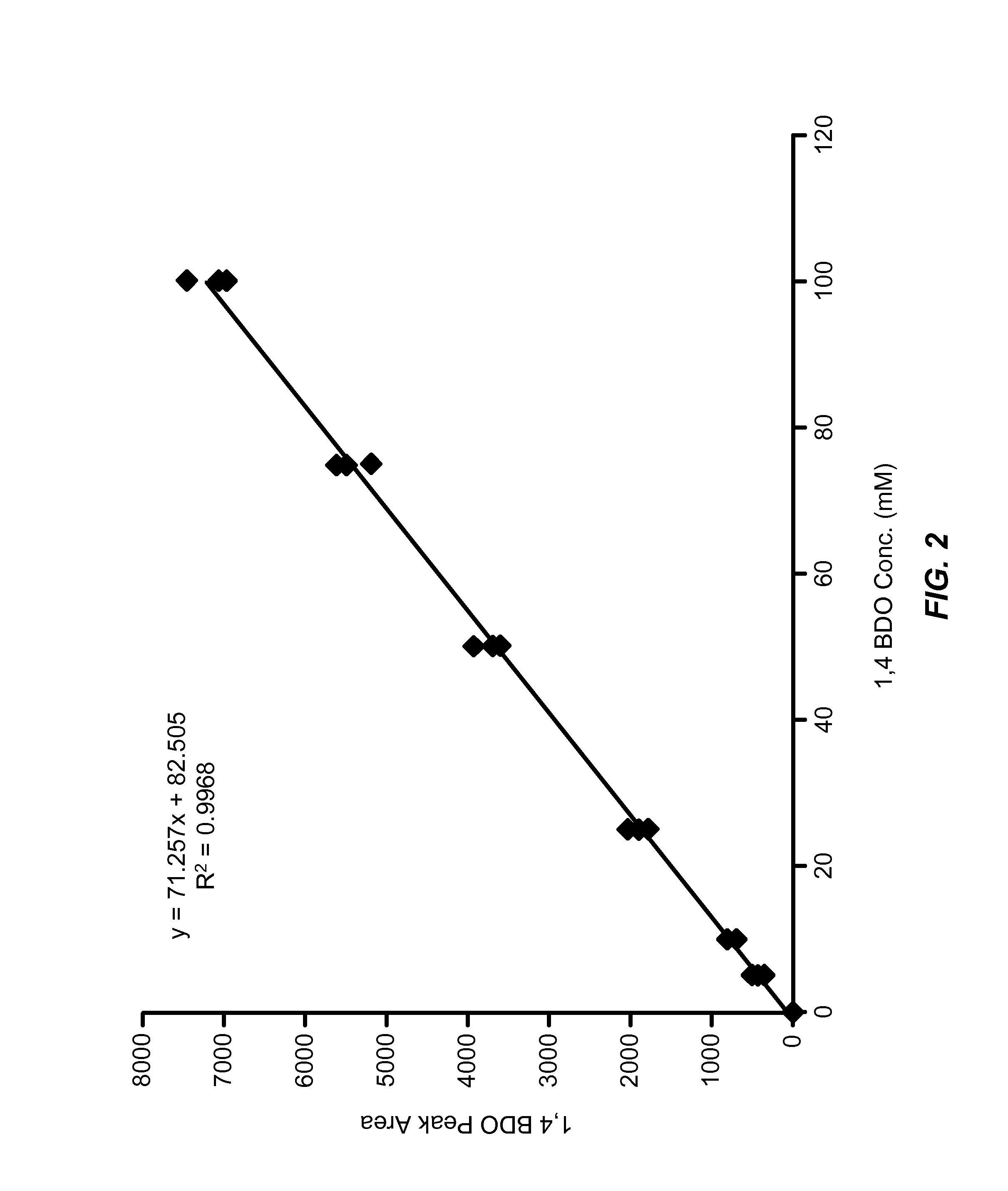

Three biosynthetic pathways are disclosed for microorganism bio-production of 1,4-Butanediol from various carbon sources. Exemplary methods are provided. The recombinant microorganisms comprising any of these 1,4-Butanediol biosynthesis pathways may also comprise genetic modifications directed to improved tolerance for 1,4-Butanediol.

Owner:OPX BIOTECH

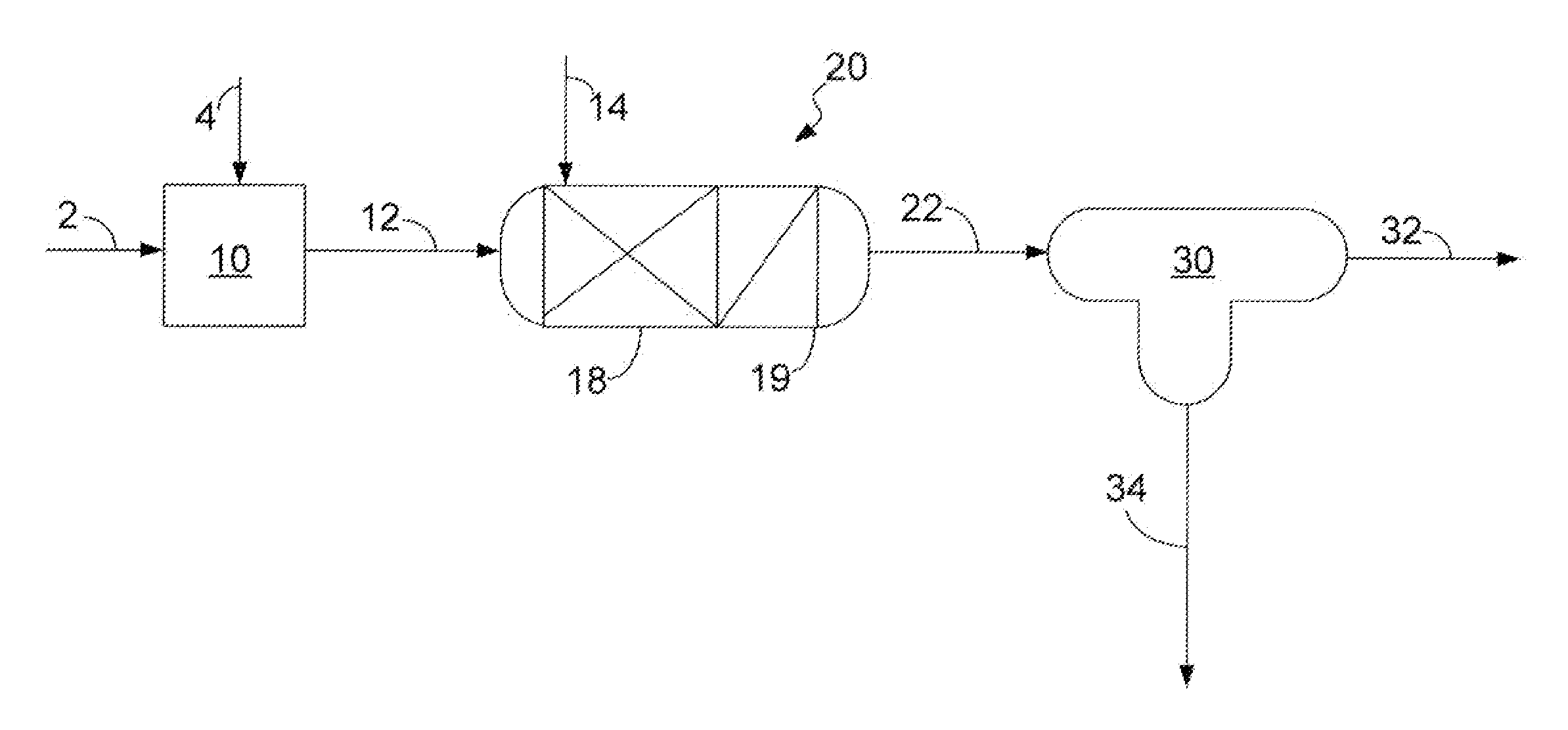

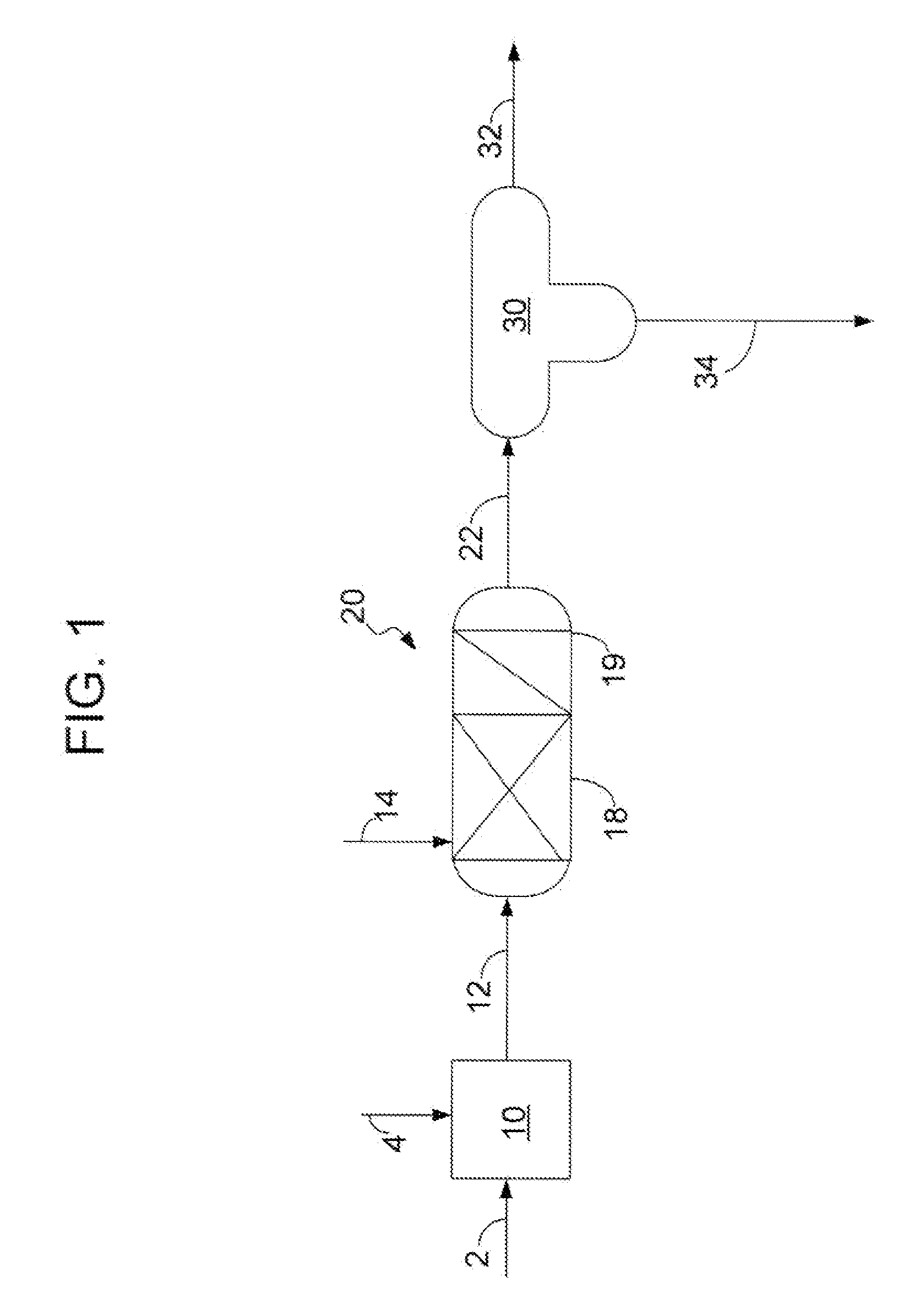

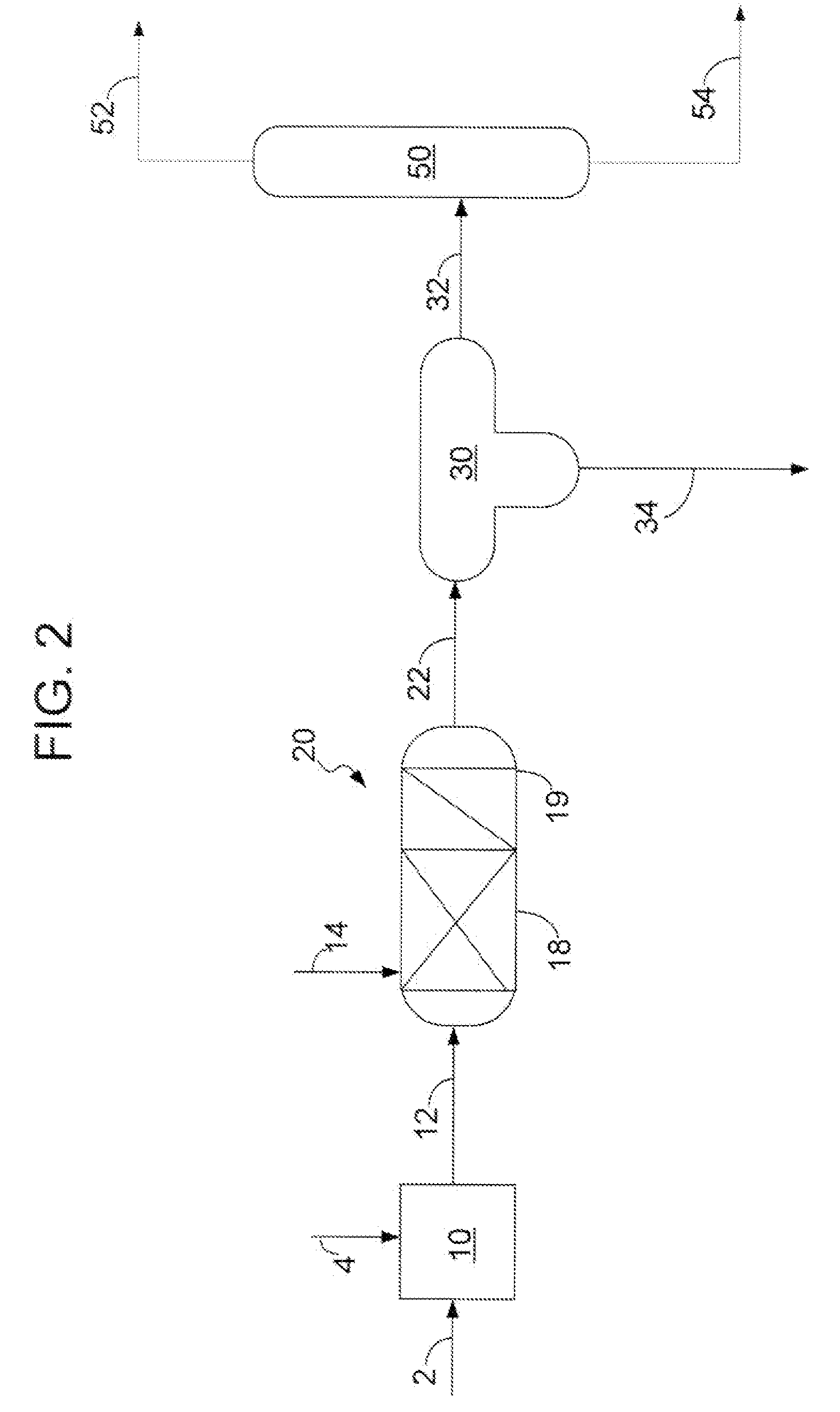

Converting Heavy Sour Crude Oil/Emulsion to Lighter Crude Oil Using Cavitations and Filtration Based Systems

ActiveUS20100122933A1Reduce sulfur contentSatisfies needTreatment with plural serial cracking stages onlyCoke ovensEmulsionChemistry

A process for converting heavy sulfur-containing crude oil into lighter crude oil with lower sulfur content and lower molecular weight is provided. The process is a low-temperature process using controlled cavitation.

Owner:SAUDI ARABIAN OIL CO

Liquid crystal composition, polymer/liquid crystal composite, liquid crystal element, and liquid crystal display device

ActiveUS20120138853A1Wider blue phase appearanceReduce the driving voltageLiquid crystal compositionsNon-linear opticsCarbonyl groupOxygen atom

A liquid crystal composition for forming a polymer / liquid crystal composite in which disorder of an orientation state is reduced is provided. The liquid crystal composition includes a liquid crystal material exhibiting a blue phase and a liquid crystalline monomer represented by the following general formula (G1). Note that the liquid crystal composition may include a non-liquid-crystalline monomer and a polymerization initiator. In the general formula (G1), X represents a mesogenic skeleton; and Y1 and Y2 individually represent an alkylene group having a sum of carbon atoms and / or oxygen atoms of 1 to 20. Also in the general formula (G1), the alkylene group and the alkyl group may include a carbonyl group and may have an ether bond. In addition, the carbonyl group and the ether bond may form an ester structure. In the general formula (G1), Z1 and Z2 individually represent an acryloyl group or a methacryloyl group.

Owner:SEMICON ENERGY LAB CO LTD

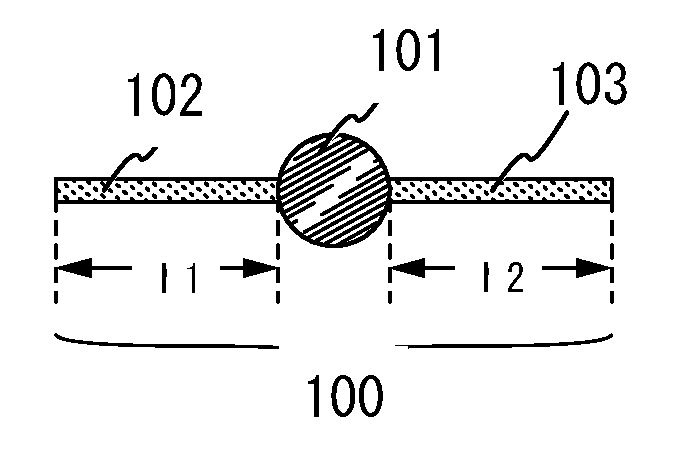

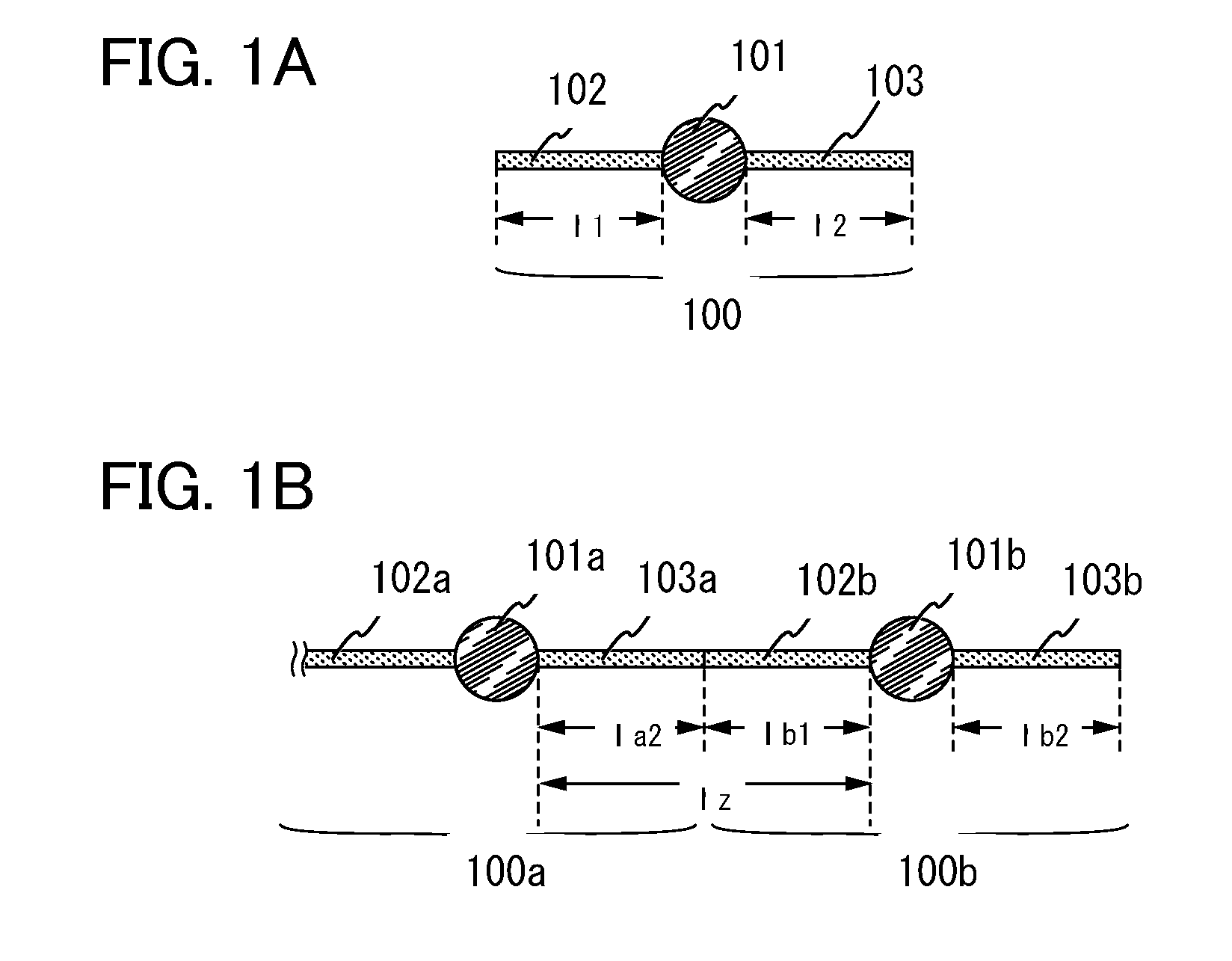

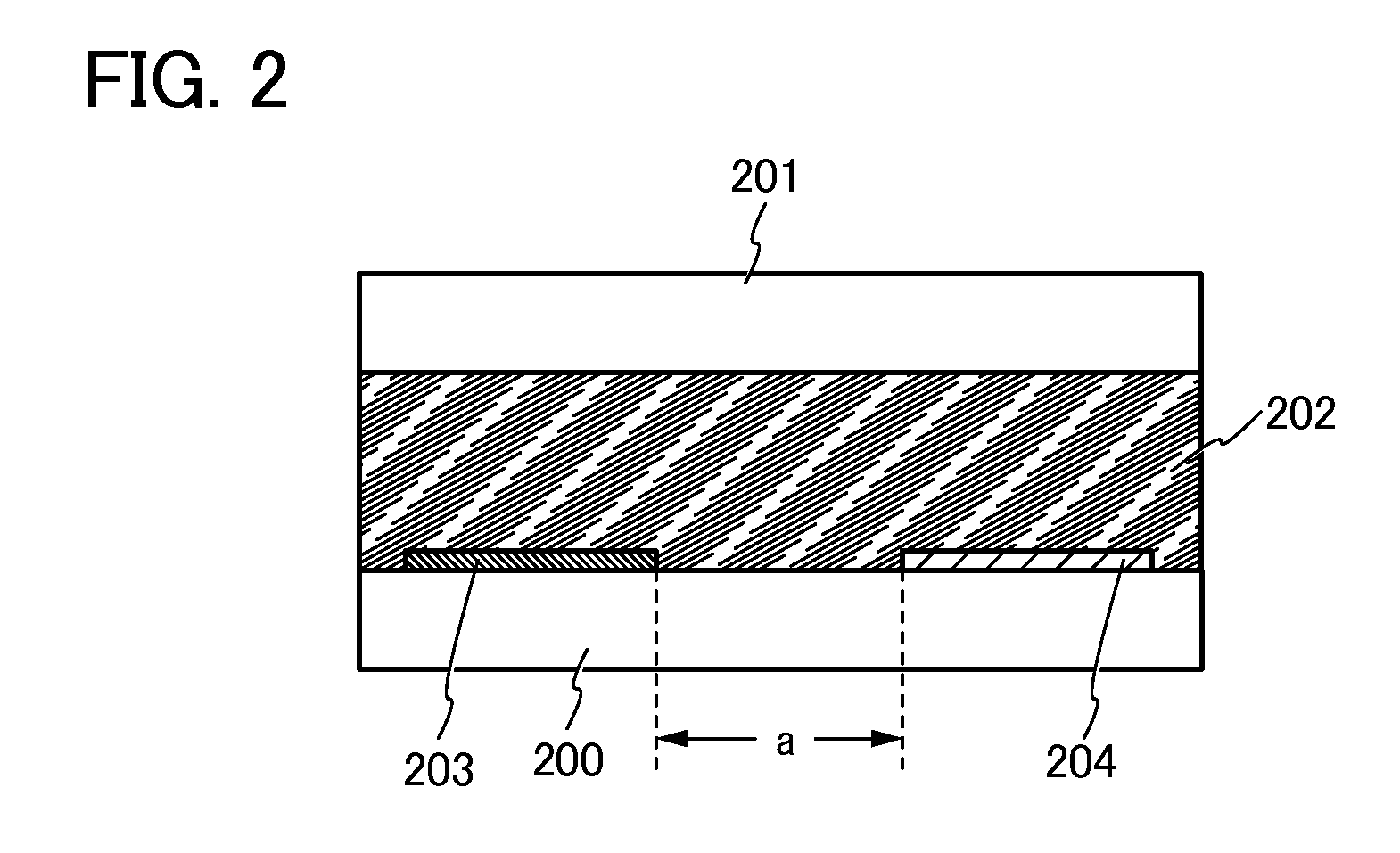

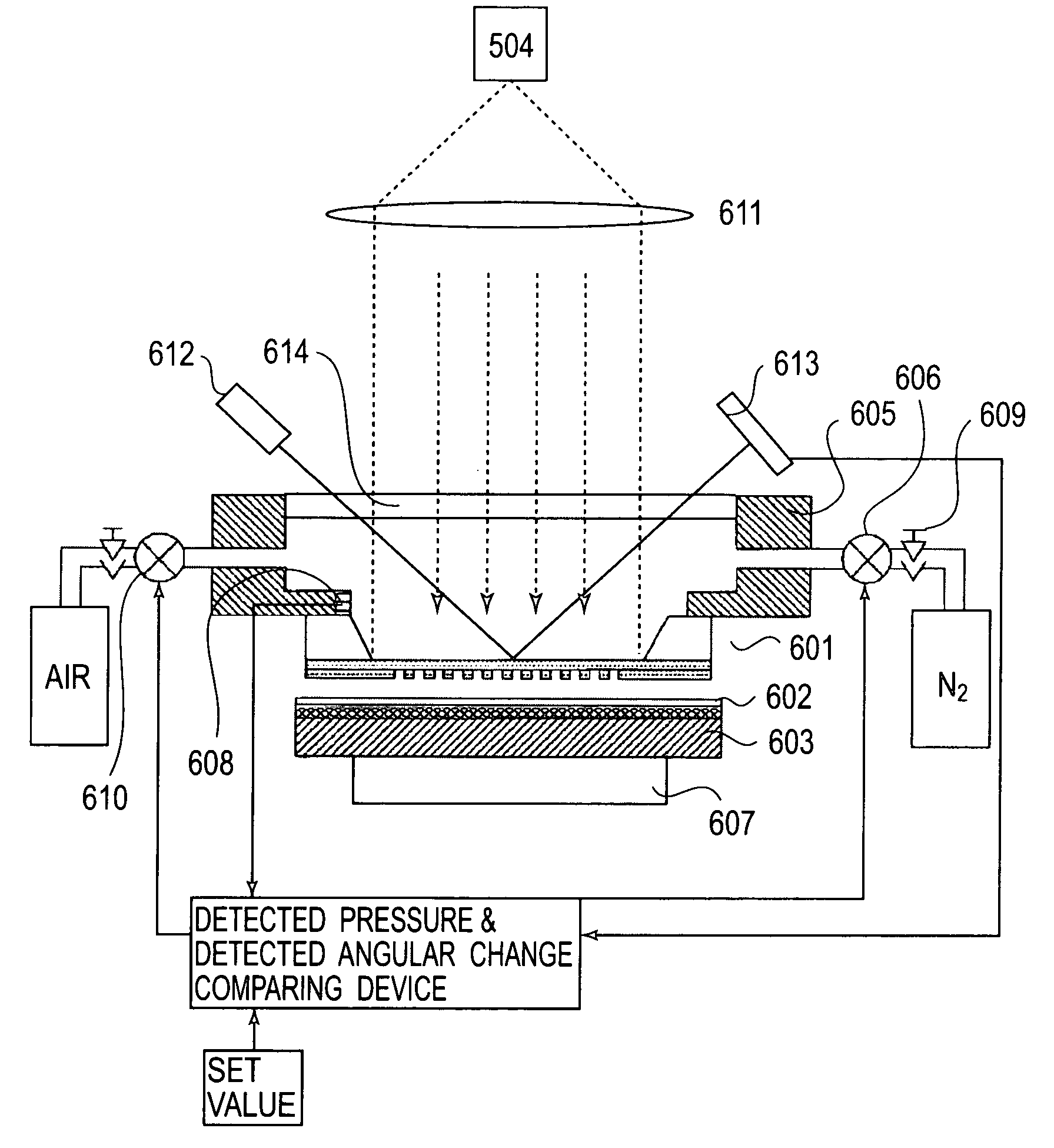

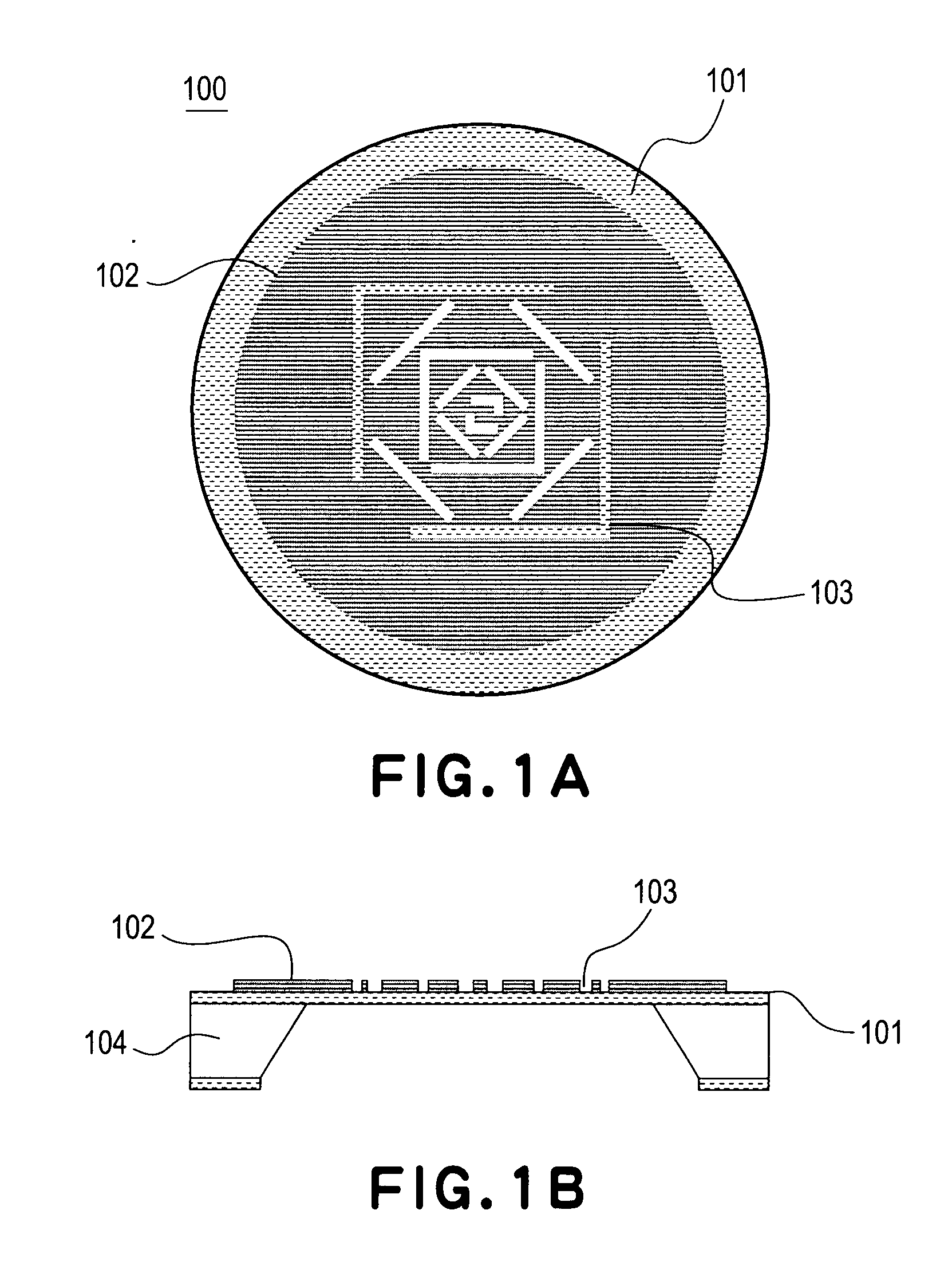

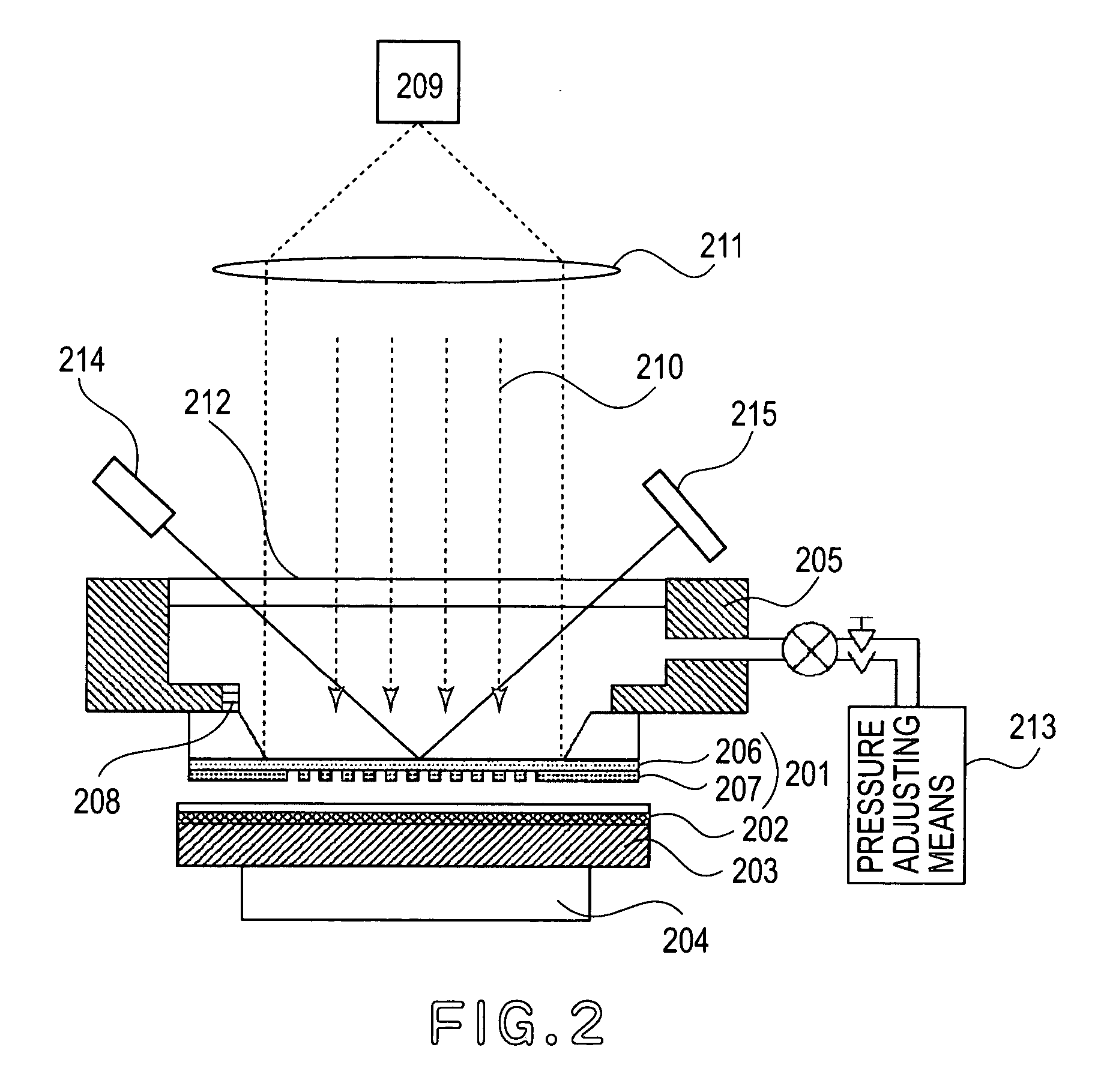

Method of detecting attracting force between substrates, and near-field exposure method and apparatus

InactiveUS20050057752A1Avoid breakingYield andNanoinformaticsSemiconductor/solid-state device manufacturingEngineeringField exposure

Disclosed is a method of detecting an attraction force between substrates, and a near-field exposure method and apparatus, wherein, in the attraction force detecting method, an elastically deformable first substrate is intimately contacted to a second substrate which is not elastically deformable as compared with the first substrate and, when the first and second substrates so contacted are separated from each other, an attraction force acting between the first and second substrates is detected. Specifically, the includes at least one of (i) a step for detecting an attraction force acting between the first and second substrates on the basis of a difference between (a) a physical quantity necessary for intimately contacting the first substrate to the second substrate and (b) a physical quantity necessary for separating the first substrate from the second substrate, and (ii) a step of detecting an attraction force acting between the first and second substrates on the basis of an amount of deformation of the first substrate relative to the second substrate.

Owner:CANON KK

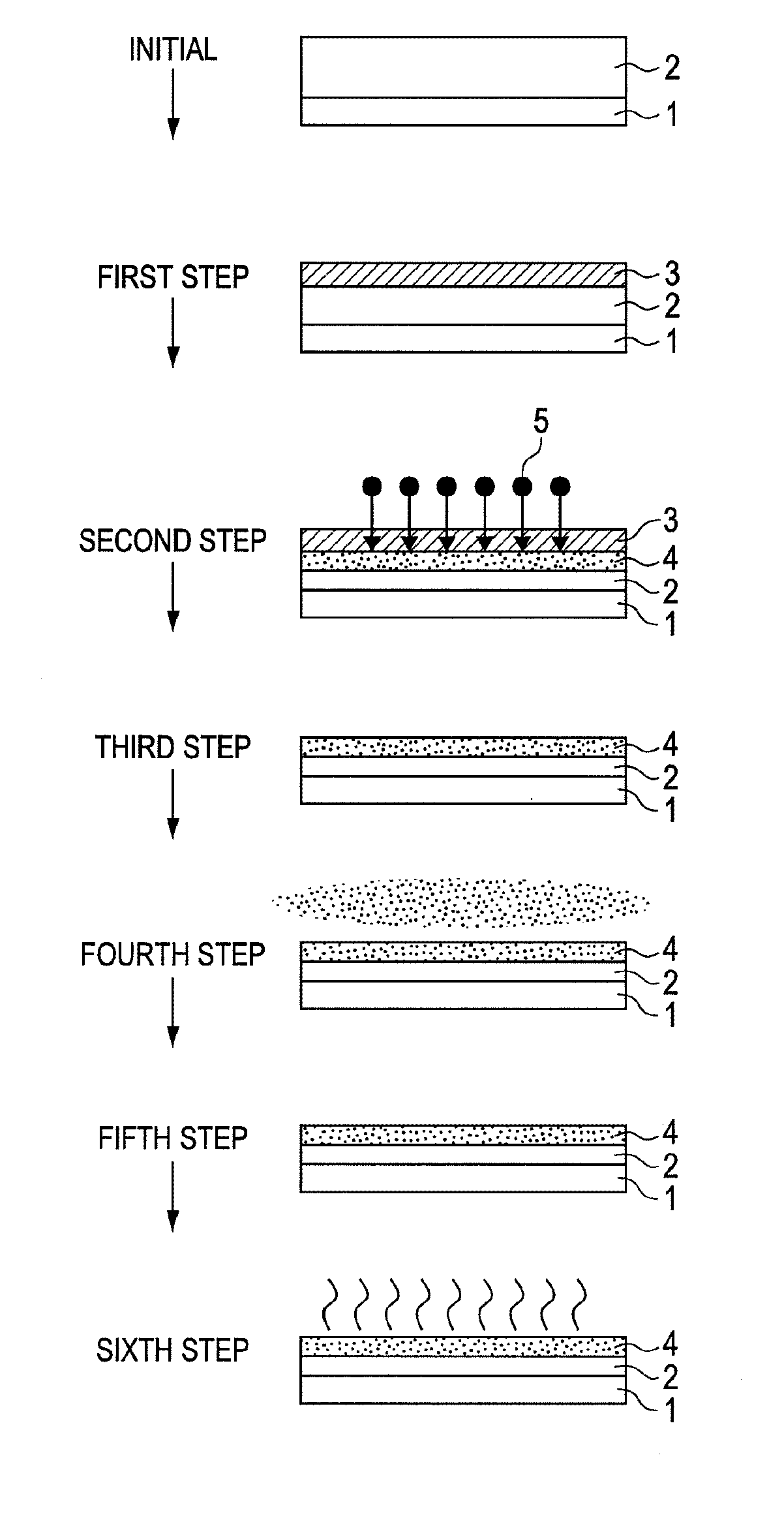

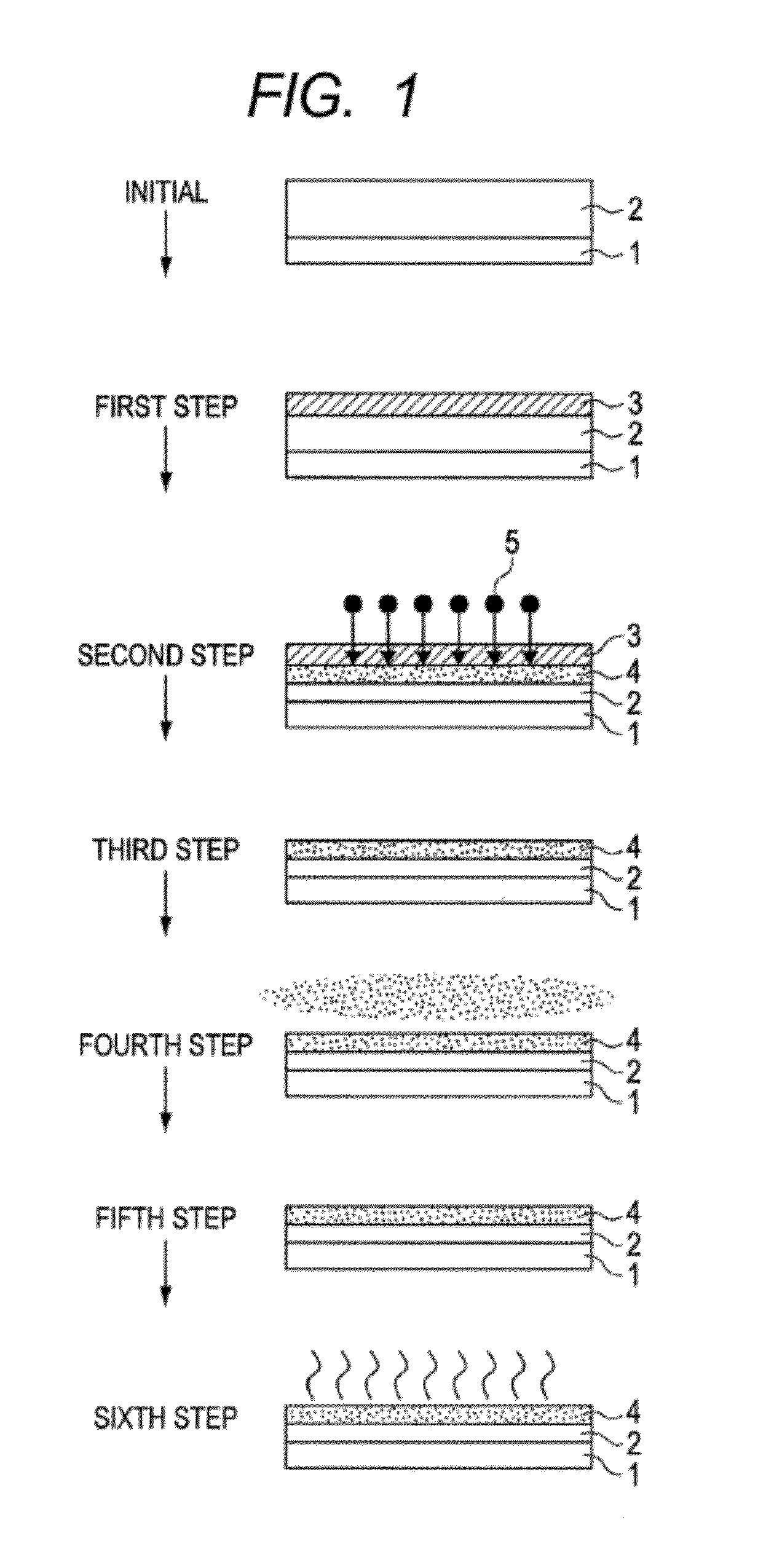

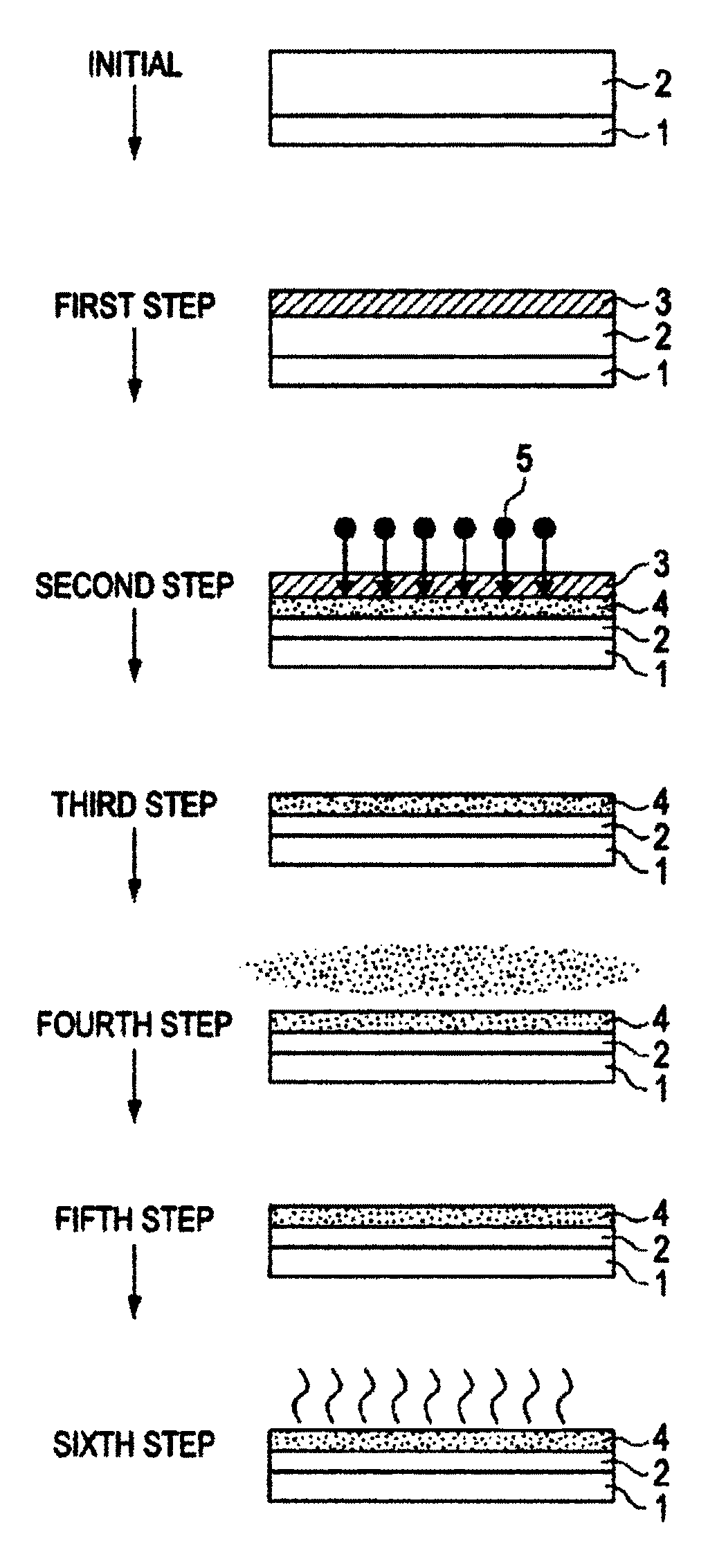

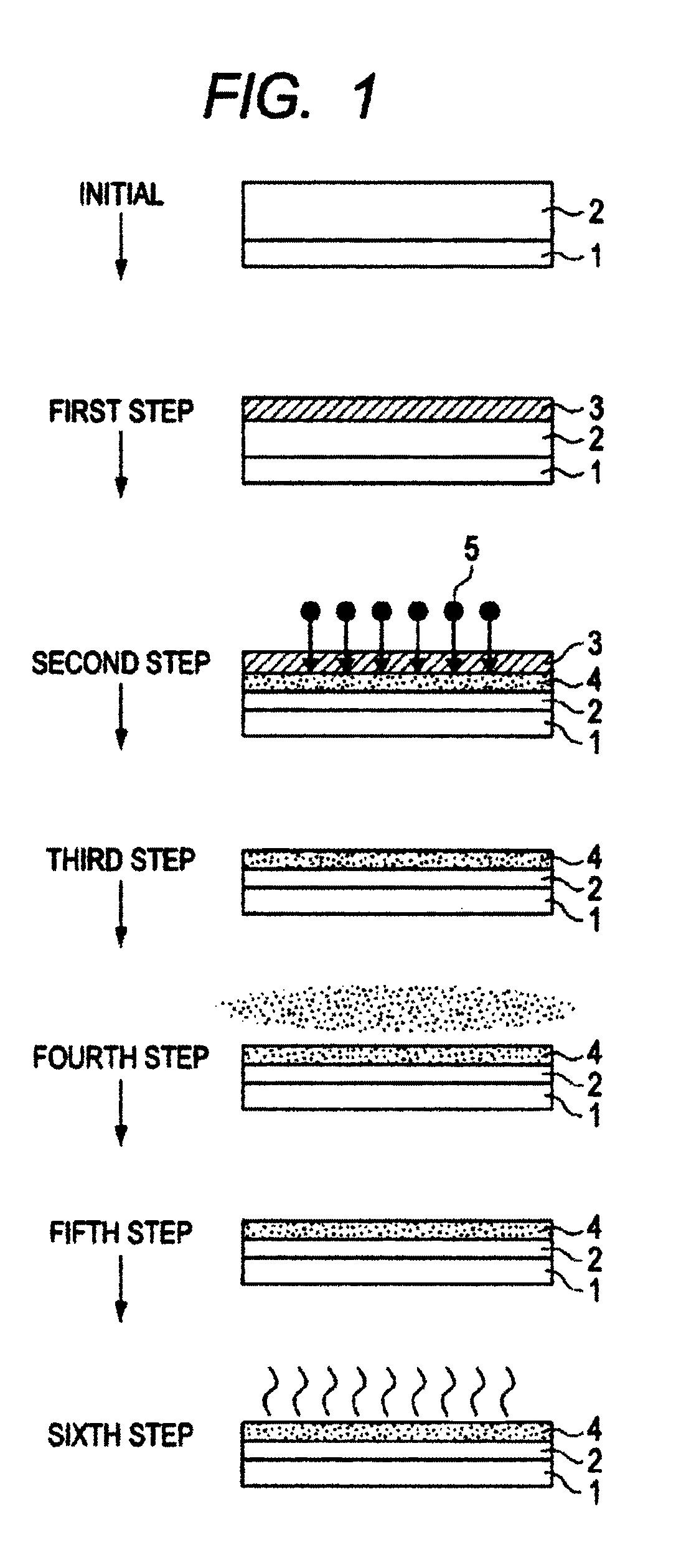

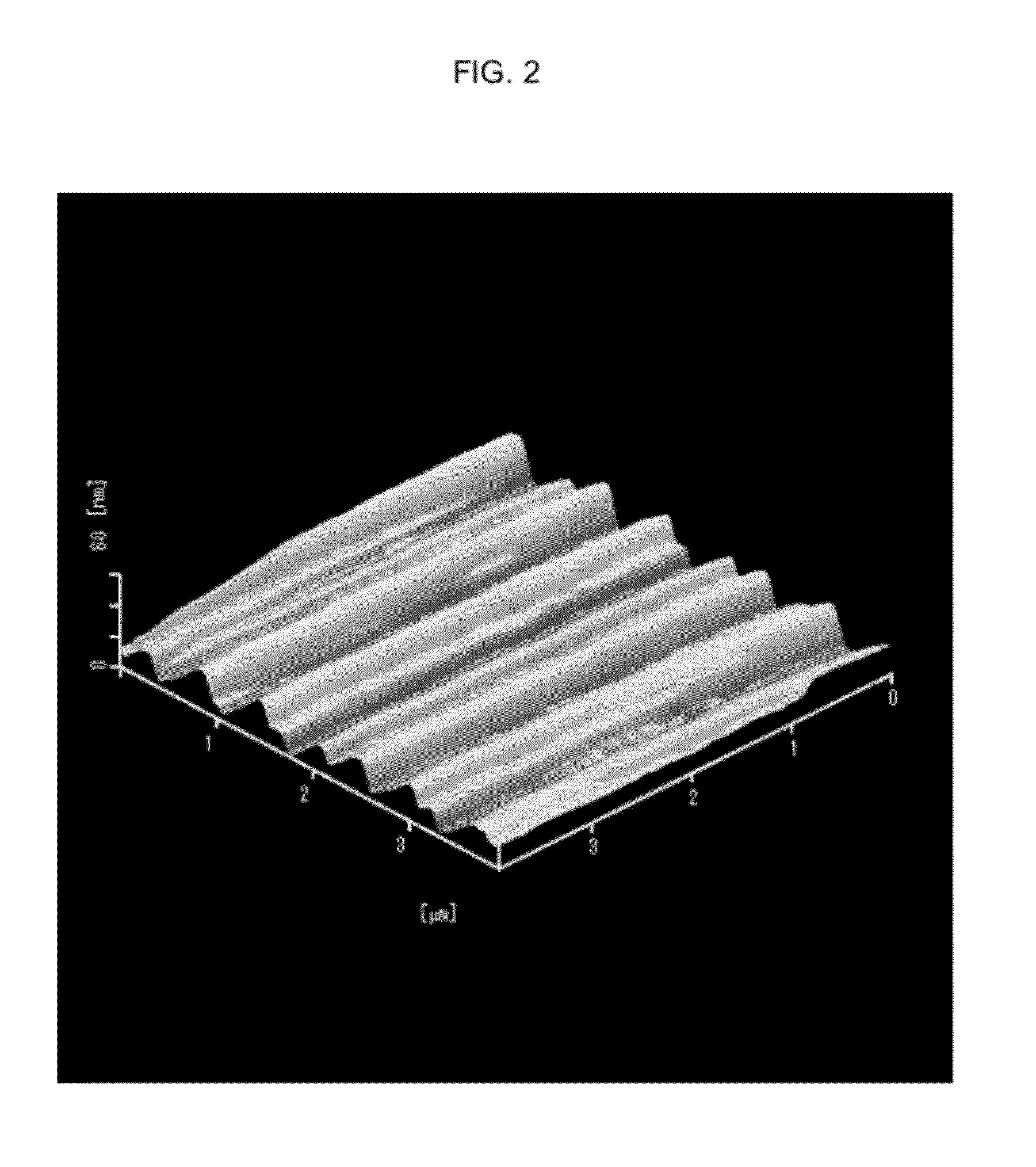

Substrate processing method and method of manufacturing crystalline silicon carbide (SIC) substrate

ActiveUS20120070968A1Reduce surface roughnessIncrease productionSemiconductor/solid-state device manufacturingSemiconductor devicesSurface roughnessCarbide

The present invention provides a method of processing a substrate and a method of manufacturing a silicon carbide (SiC) substrate in which, when annealing processing is performed on a crystalline silicon carbide (SiC) substrate, the occurrence of surface roughness is suppressed. A substrate processing method according to an embodiment of the present invention includes a step of performing plasma irradiation on a single crystal silicon carbide (SiC) substrate (1) and a step of performing high temperature heating processing on the single crystal silicon carbide (SiC) substrate (1) in which the plasma irradiation is performed.

Owner:CANON ANELVA CORP

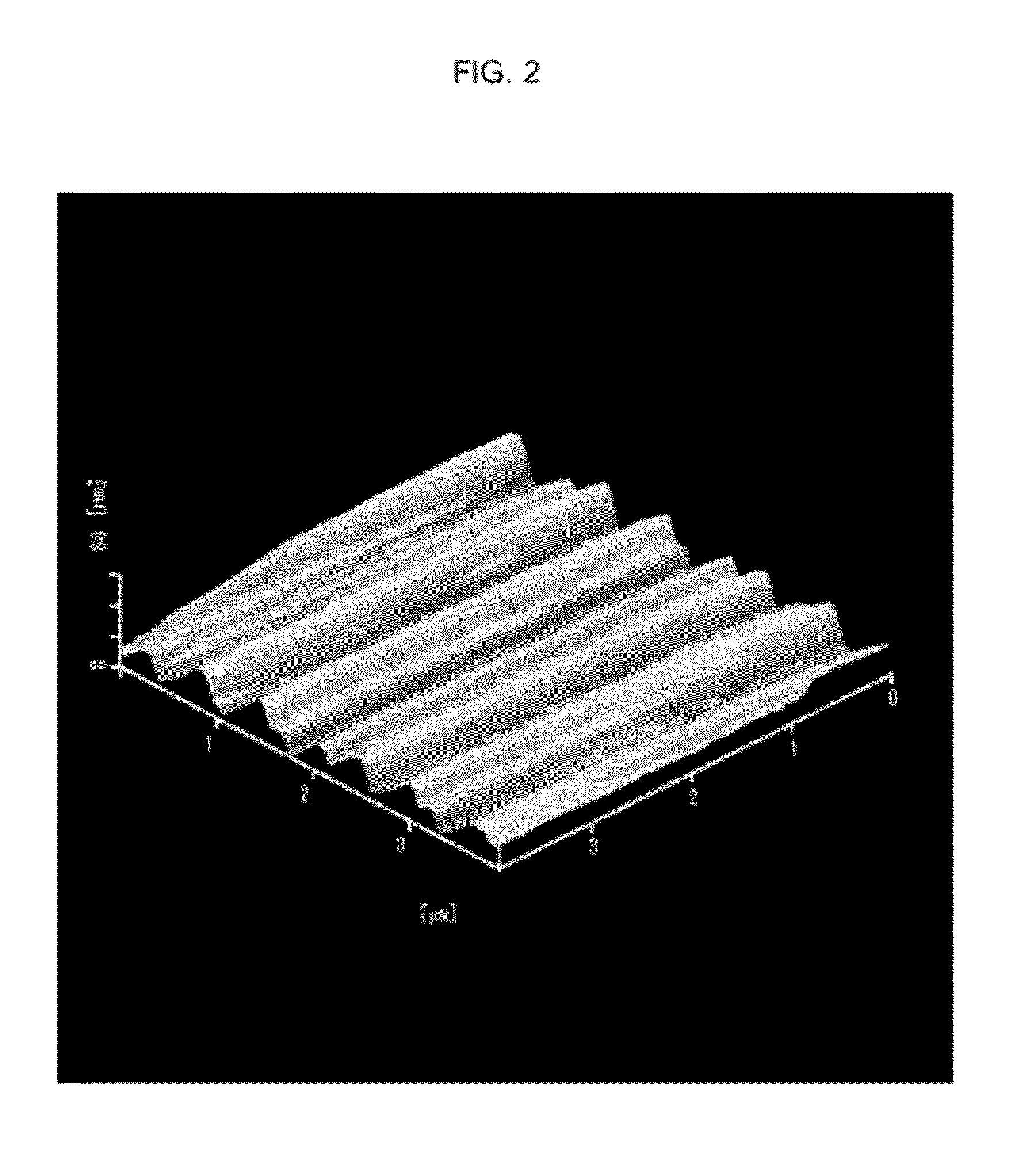

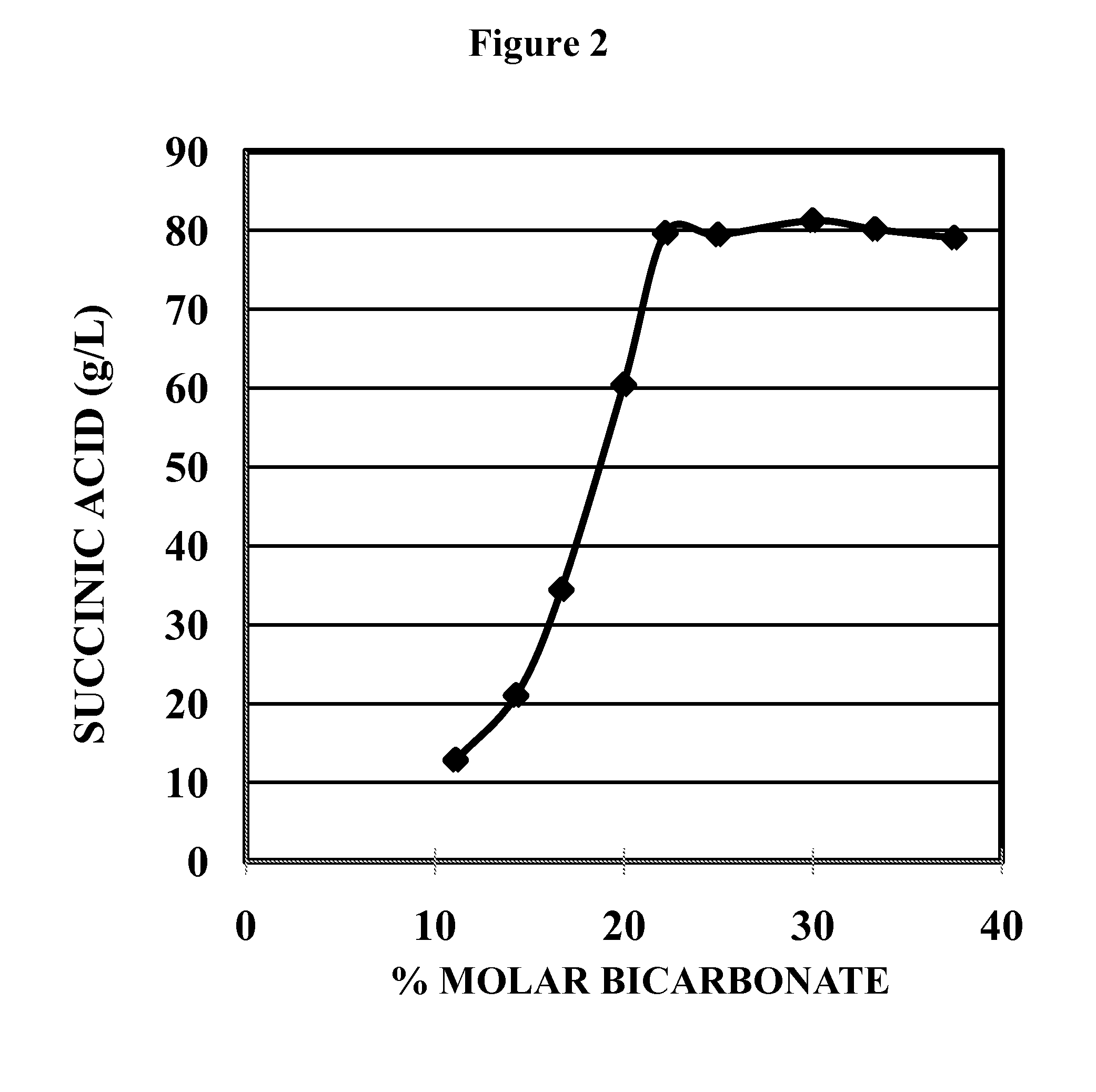

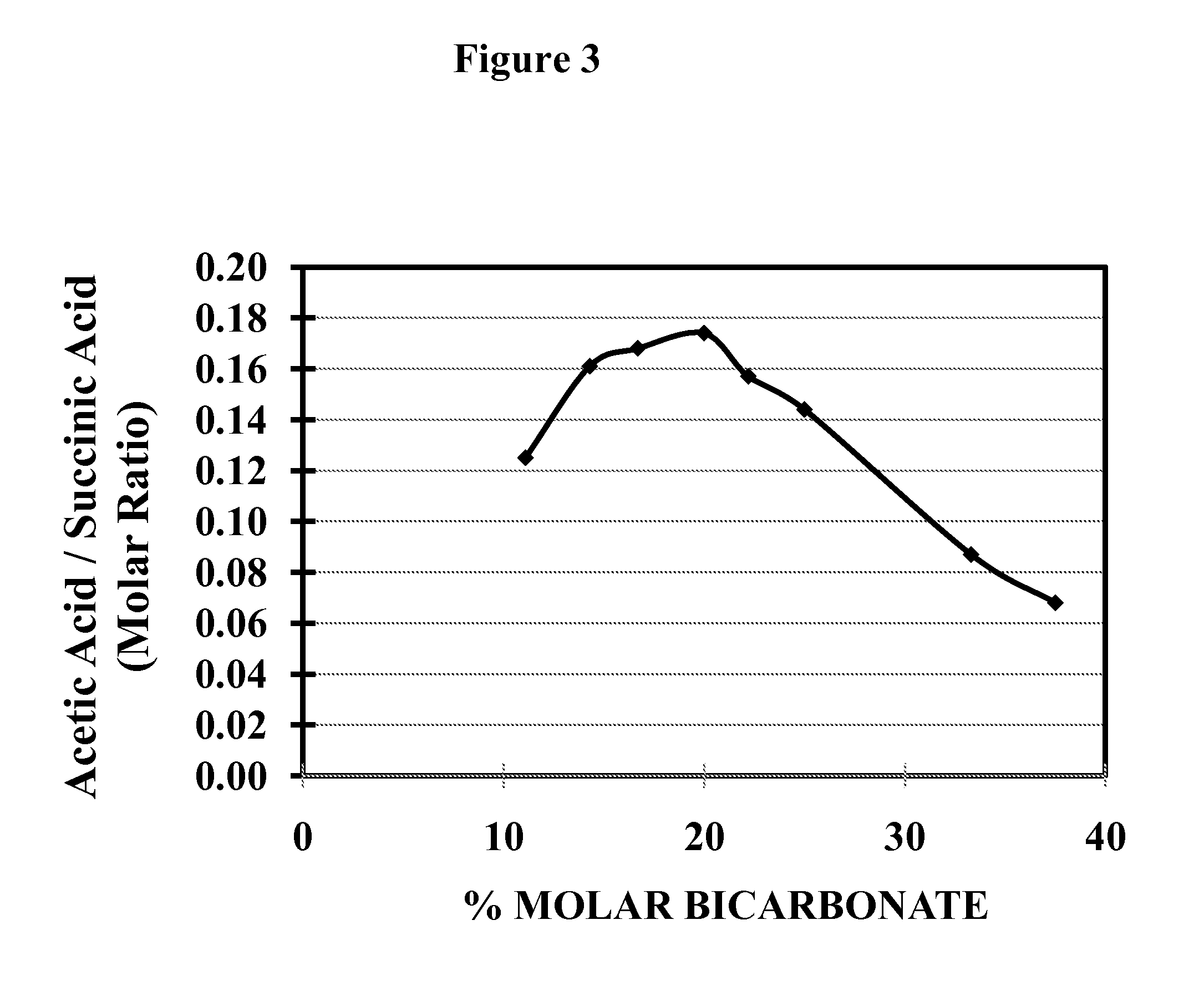

Fermentation process for the production of organic acids

This invention relates to improvements in the fermentation process used in the production of organic acids from biological feedstock using bacterial catalysts. The improvements in the fermentation process involve providing a fermentation medium comprising an appropriate form of inorganic carbon, an appropriate amount of aeration and a biocatalyst with an enhanced ability to uptake and assimilate the inorganic carbon into the organic acids. This invention also provides, as a part of an integrated fermentation facility, a novel process for producing a solid source of inorganic carbon by sequestering carbon released from the fermentation in an alkali solution.

Owner:MYRIANT CORP

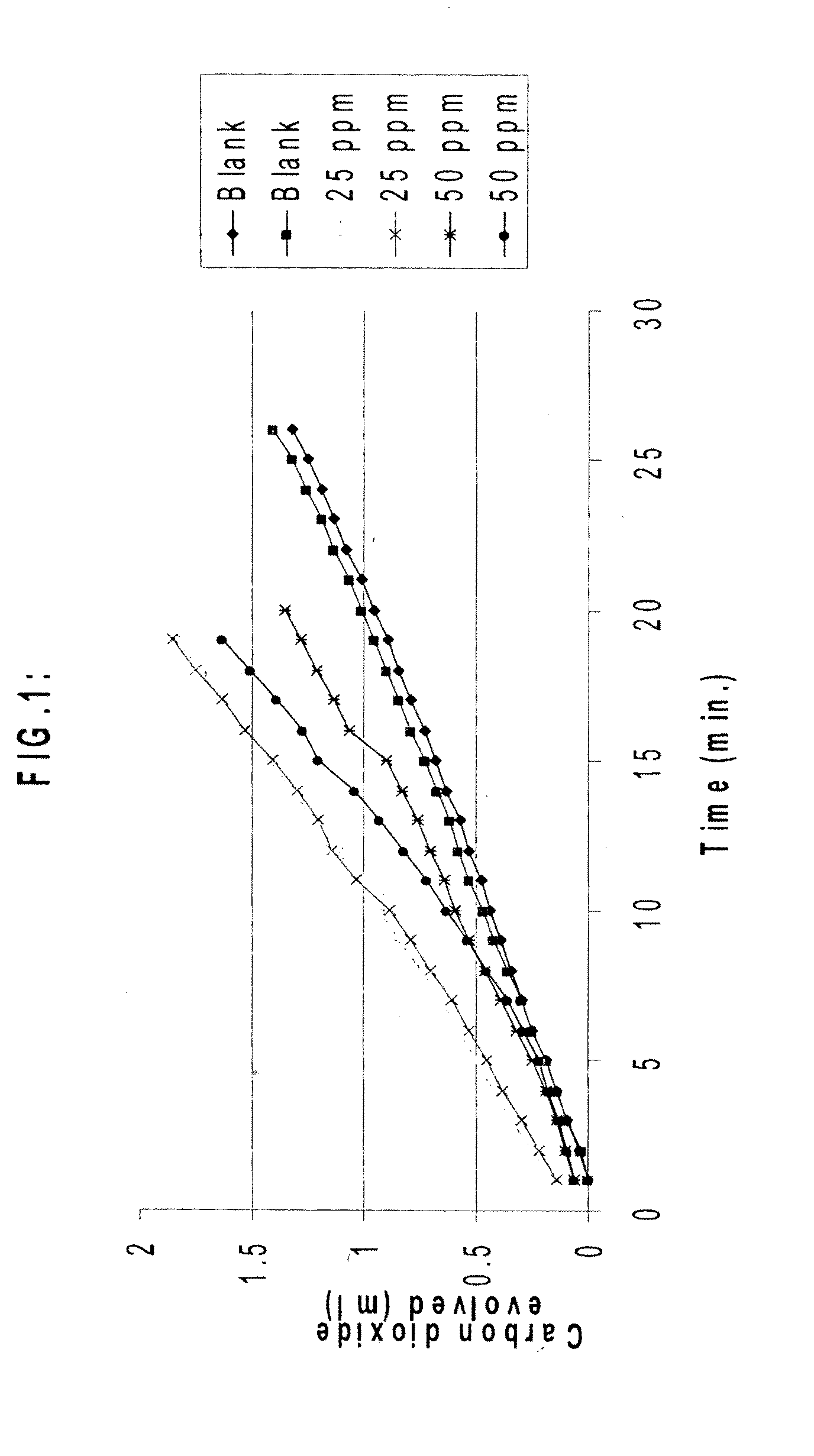

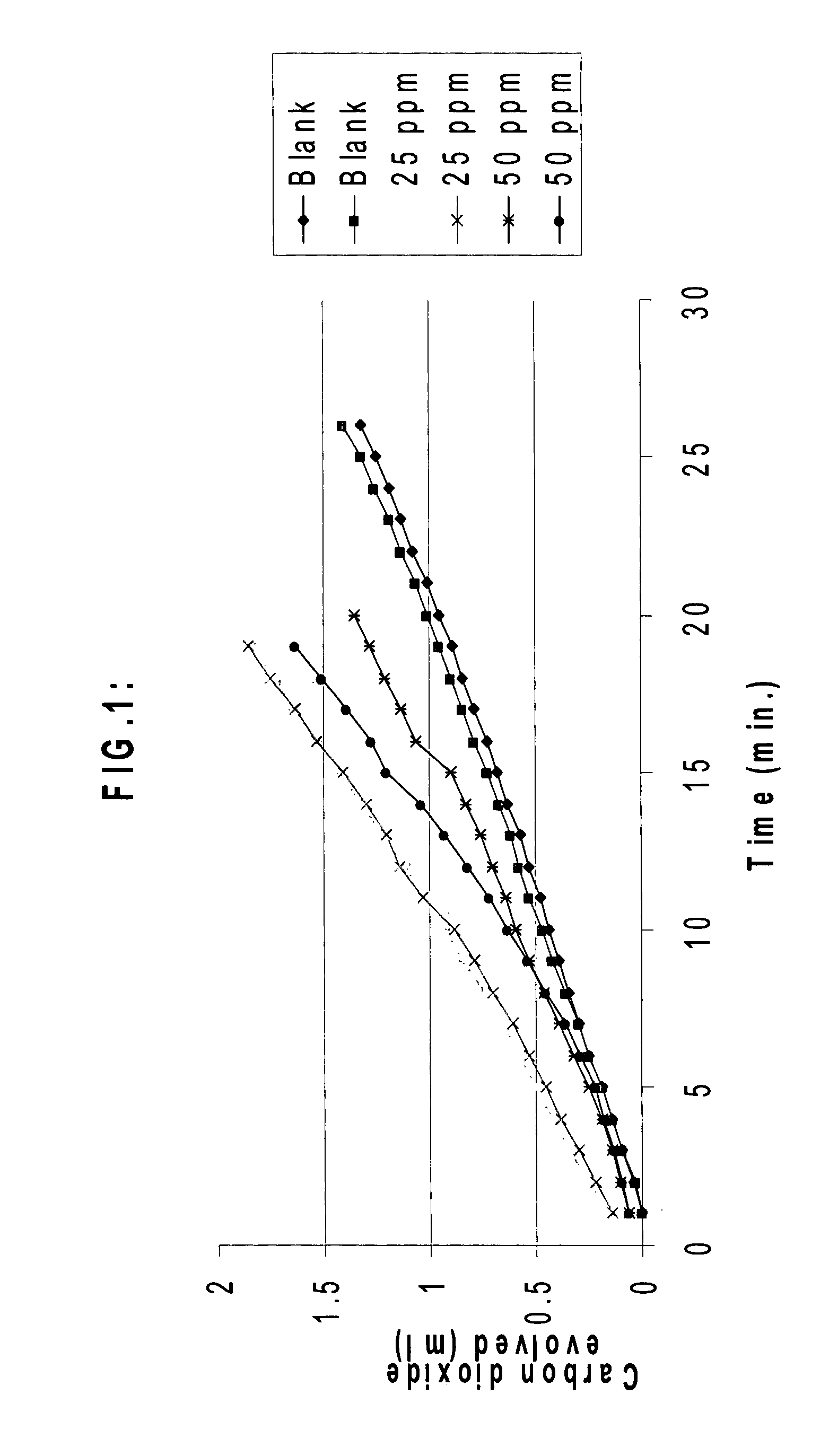

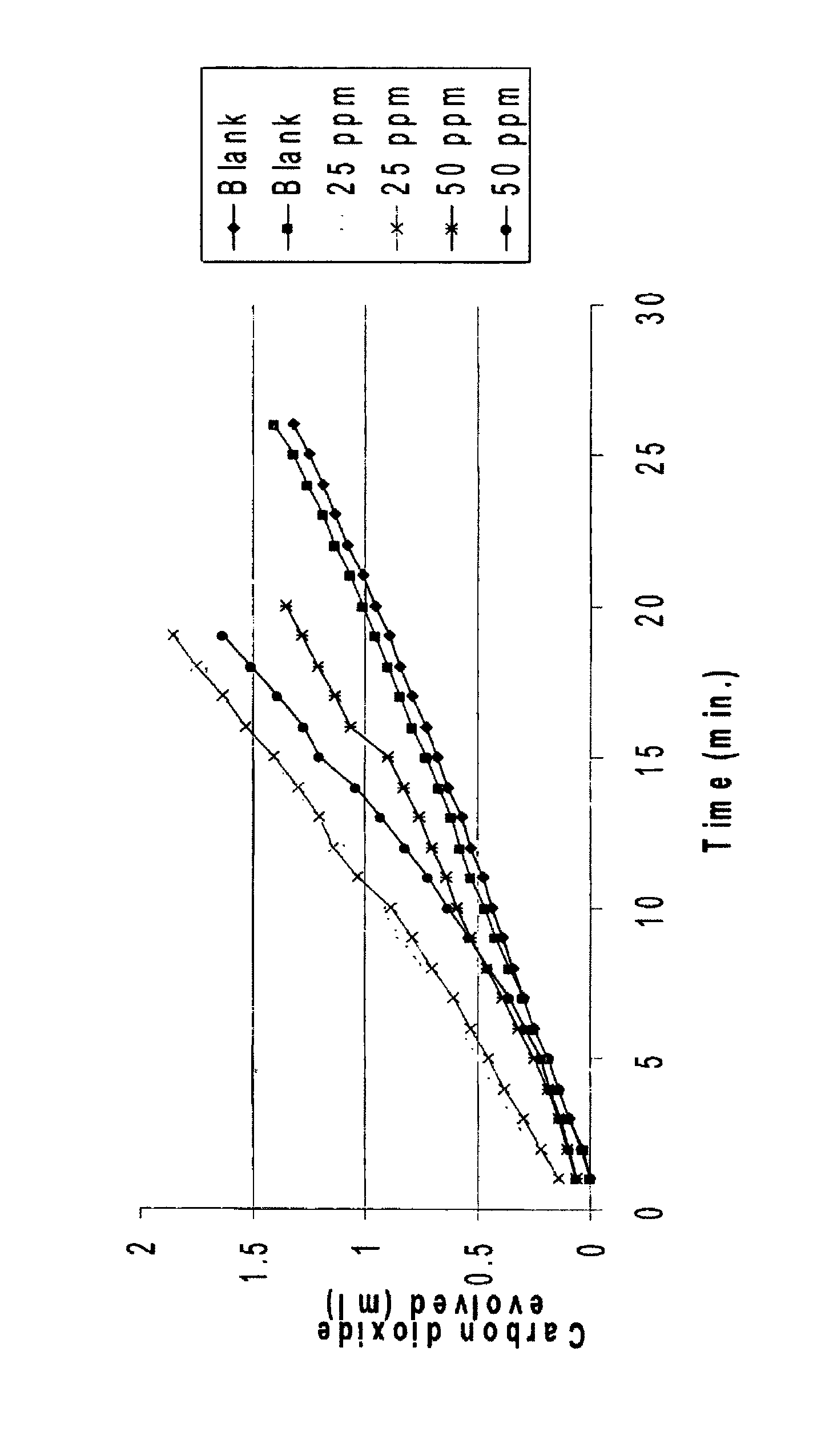

Composition and Methods for Improving the Production of Fermentation Operations

Methods and compositions for improving the production of ethanol by a microorganism in a fermentation medium are provided, where the method comprises adding to the fermentation medium an emulsion comprising a monoterpene and a surfactant in an amount sufficient to improve the production of ethanol.

Owner:POLYMER VENTURES

Additive to maximize GLP and propene suitable for use in low-severity operations of a fluid catalytic cracking unit and its preparatory process

ActiveUS20080015105A1Minimizing LCO range hydrocarbon crackingHigh activityCatalytic crackingMolecular sieve catalystsReaction temperaturePhysical chemistry

A process for the preparation and modification of additives, with a zeolite base and a high silica alumina ratio (SAR) like the ZSM-5, to increase the yield of propene and LPG in low severity FCC operations, that seeks to maximize the production of medium-distillates with low aromaticity and to minimize molecular cracking in the LCO range. The additives involved guarantee an increase in light olefin yields without altering the yield or the quality of the LCO produced. The innovative process includes surprising actions from rare earths (RE) on the active sites of zeolite, that at once partially block their pores and, in this way, make molecular cracking in the medium-distillate range difficult, which preferably occur at low reaction temperatures and keeps the remaining sites quite active. These sites are sufficiently active to crack smaller molecules in the gasoline range, guaranteeing an overall increase in light olefins and allowing the additive involved to be used industrially in operations to maximize medium-distillates in an FCC unit. This new additive may be obtained by modifying any commercial ZSM-5 zeolite additive.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

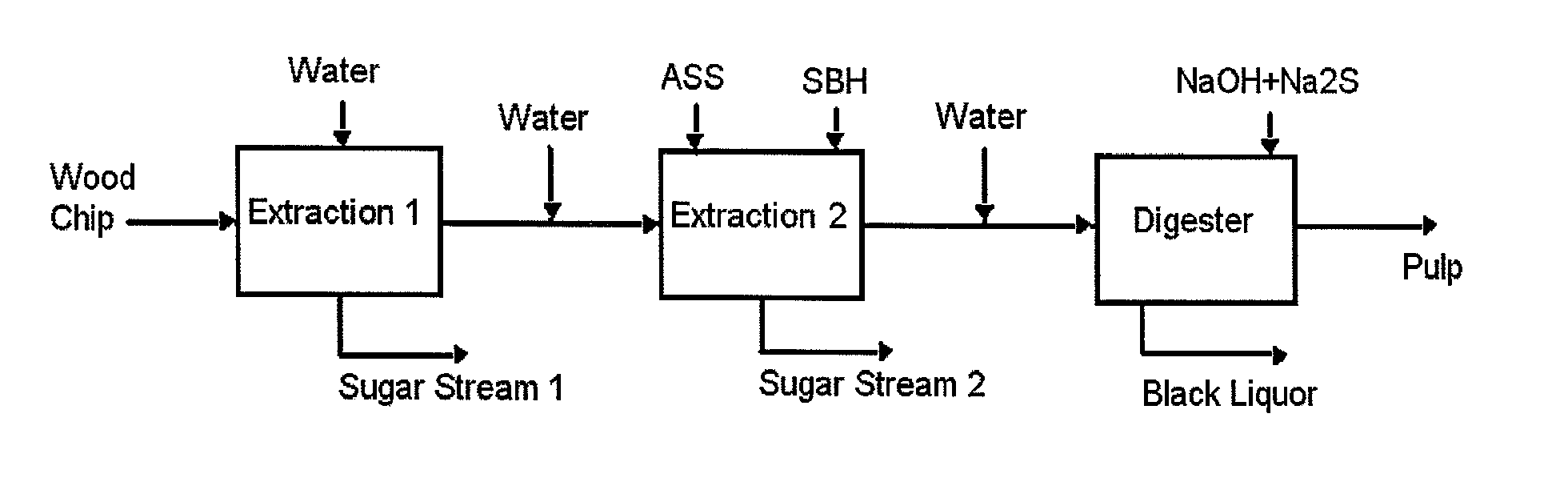

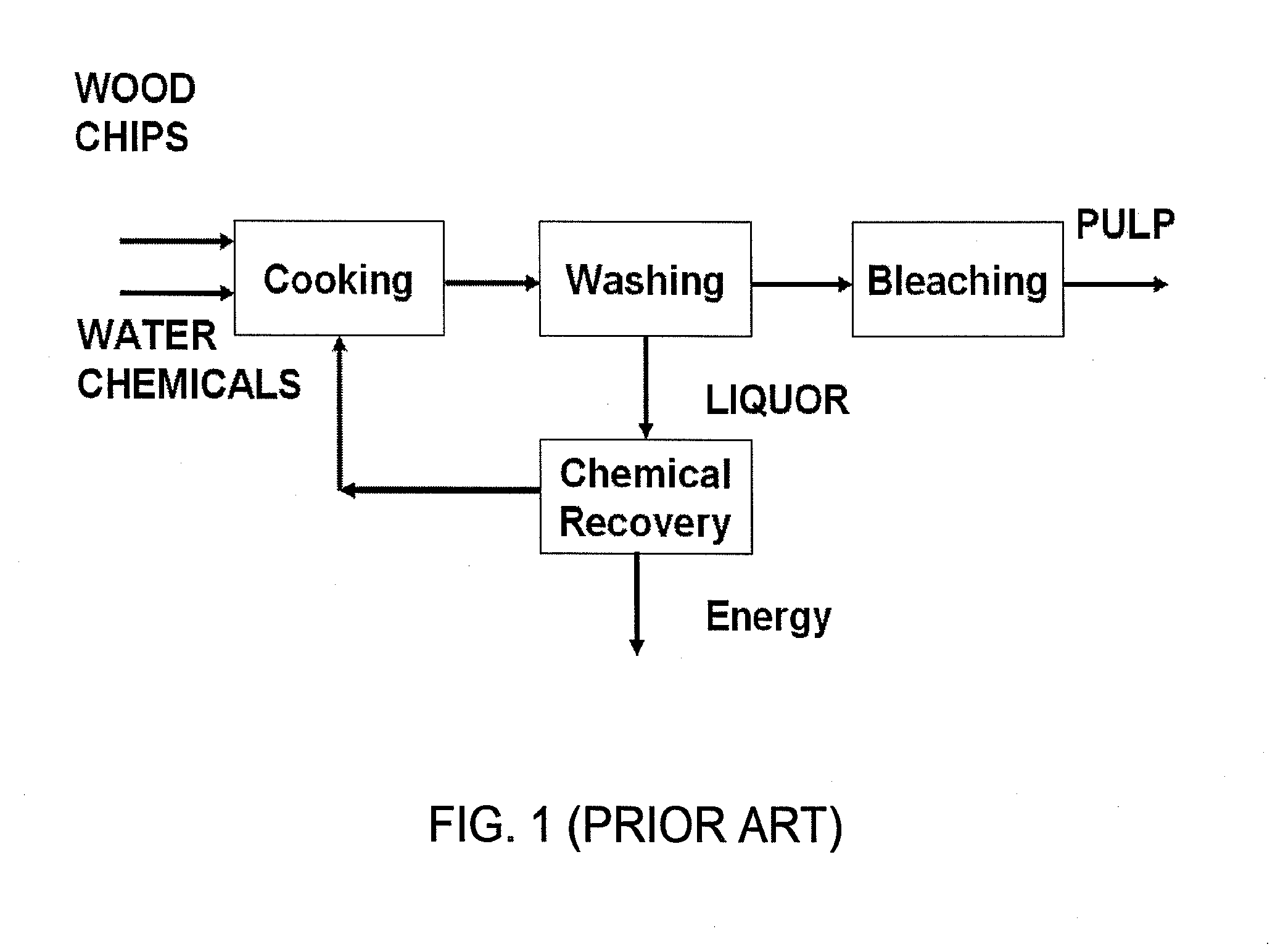

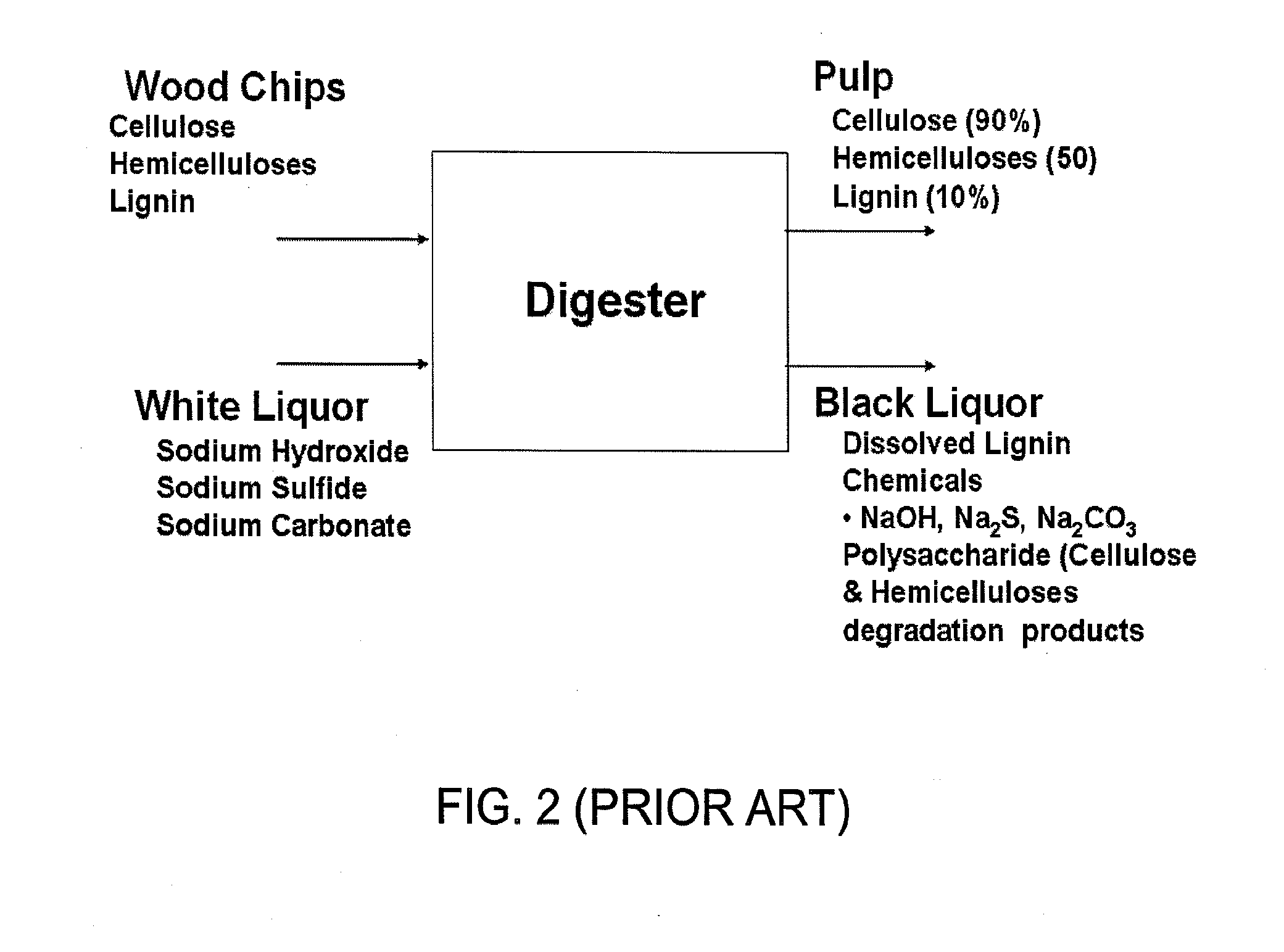

Pulping process for quality protection including methods for hemicellulose extraction and treatment of hemicellulose-extracted lignocellulosic materials

InactiveUS20120168102A1Process economyYield andPretreatment with water/steamPulp liquor regenerationPre treatmentHemicellulose

A method for producing pulp by extracting hemicellulosic materials from lignocellulosic materials using water in an extraction stage, wherein the extraction stage is either a single extraction or a double extraction process; treating the lignocellulosic materials with an oxidizing agent in a treatment stage, wherein the treatment stage is selected from the group consisting of a second extraction process, an agent impregnation process, and a first pretreatment process; treating the lignocellulosic materials with a reducing agent in the treatment stage, wherein the treatment stage is selected from the group consisting of the second extraction process, the agent impregnation process, and a second pretreatment process; and then subjecting the lignocellulosic materials to a modified Kraft pulping process to produce pulp.

Owner:YOON SUNG HOON +2

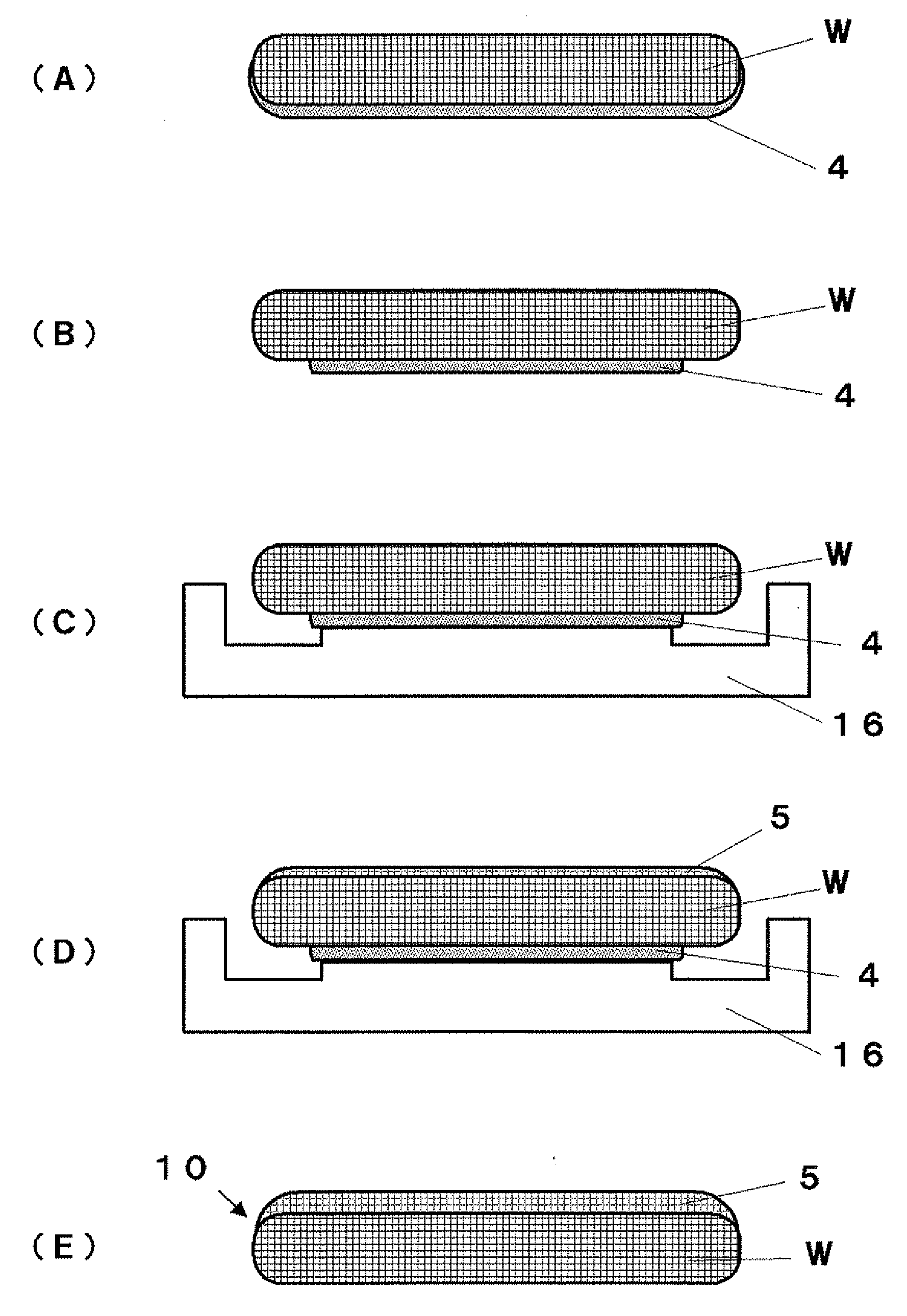

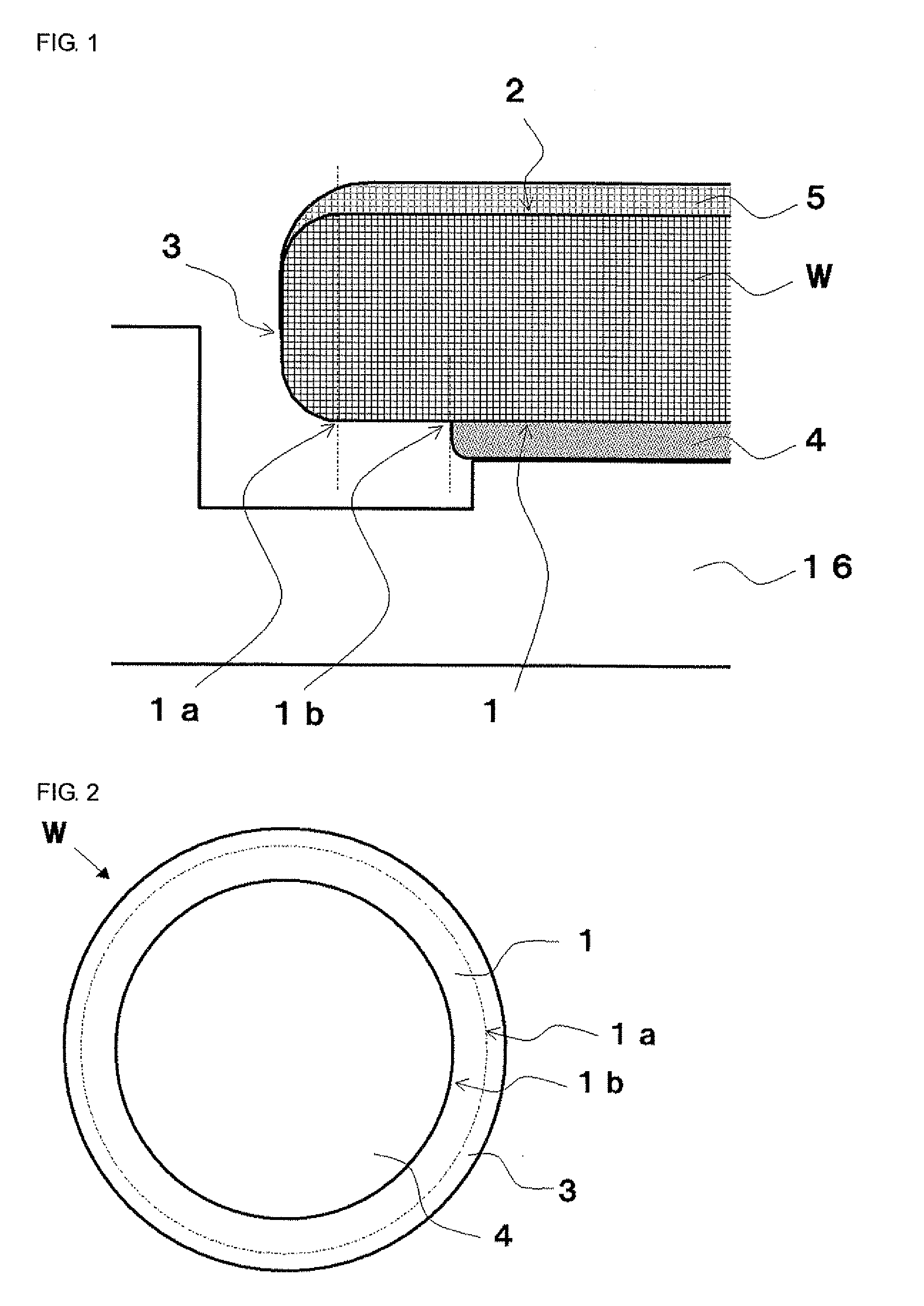

Silicon epitaxial wafer and manufacturing method thereof

ActiveUS20100327415A1Reduce Particle GenerationYield andPolycrystalline material growthSemiconductor/solid-state device manufacturingSusceptorWafering

Provided is a method for manufacturing a silicon epitaxial wafer by growing an epitaxial layer by placing a silicon substrate on a susceptor. The method includes at least a step of forming a silicon oxide film entirely on the rear surface of the silicon substrate; a step of removing the silicon oxide film formed at least on an edge section of the silicon substrate; and a step of placing the silicon substrate on the susceptor with the silicon oxide film in between. An epitaxial layer is grown on the silicon substrate, while holding the silicon substrate by the susceptor with the silicon oxide film in between. Thus, the silicon epitaxial wafer by which generation of particles can be reduced in a device manufacturing process and a method for manufacturing such silicon epitaxial wafer are provided.

Owner:SHIN-ETSU HANDOTAI CO LTD

Method of producing monodisperse chelate resins

ActiveUS20090045137A1High degree of substitutionImprove separation efficiencyWaste water treatment from quariesGas treatmentNitrogenCrosslinked polymers

The present invention relates to a method of producing novel monodisperse chelate resins based on crosslinked polymer beads containing aminomethyl groups and / or aminomethyl nitrogen heterocyclic groups that have a high uptake capacity for heavy metals and rapid kinetics.

Owner:LANXESS DEUTDCHLAND GMBH

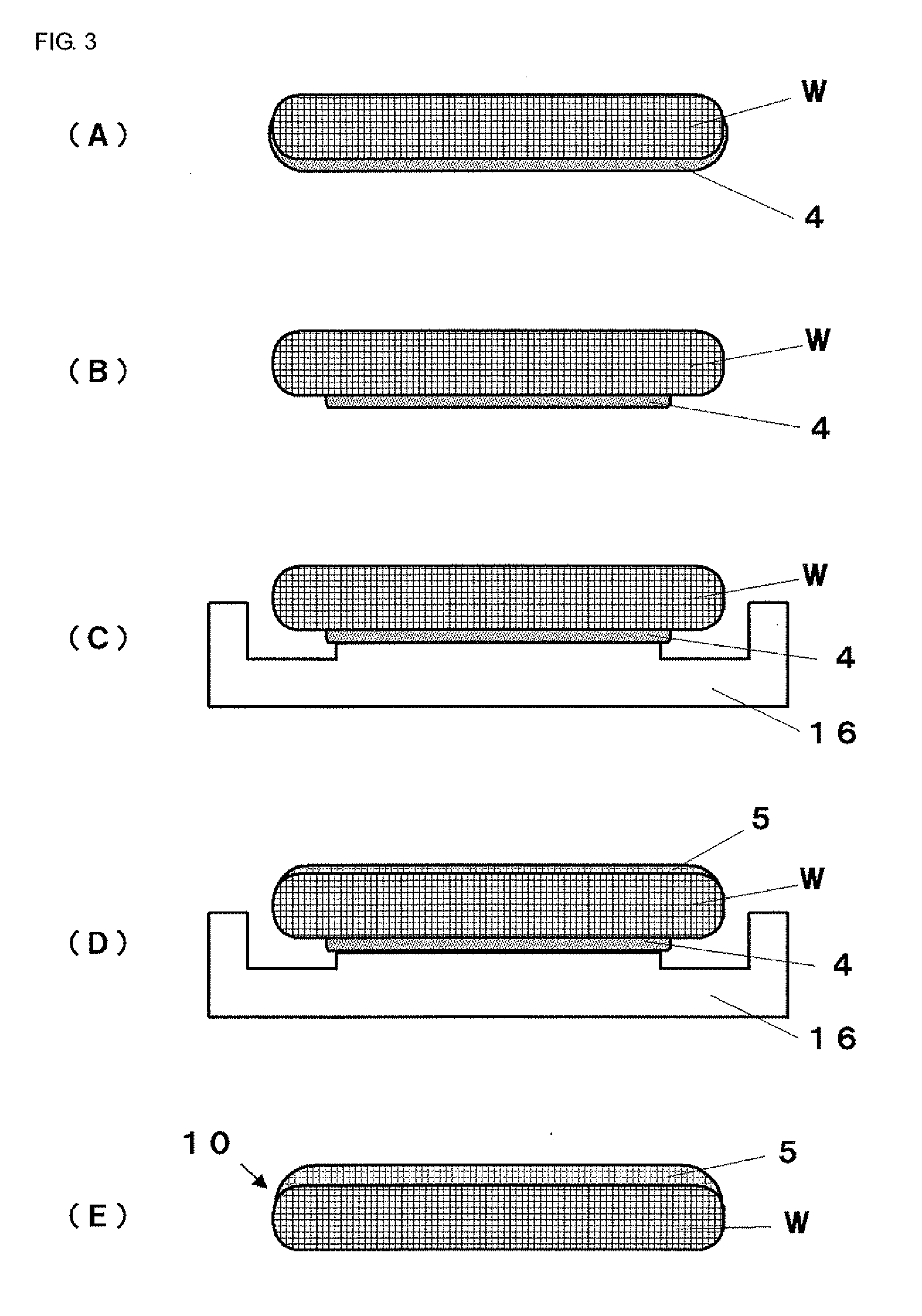

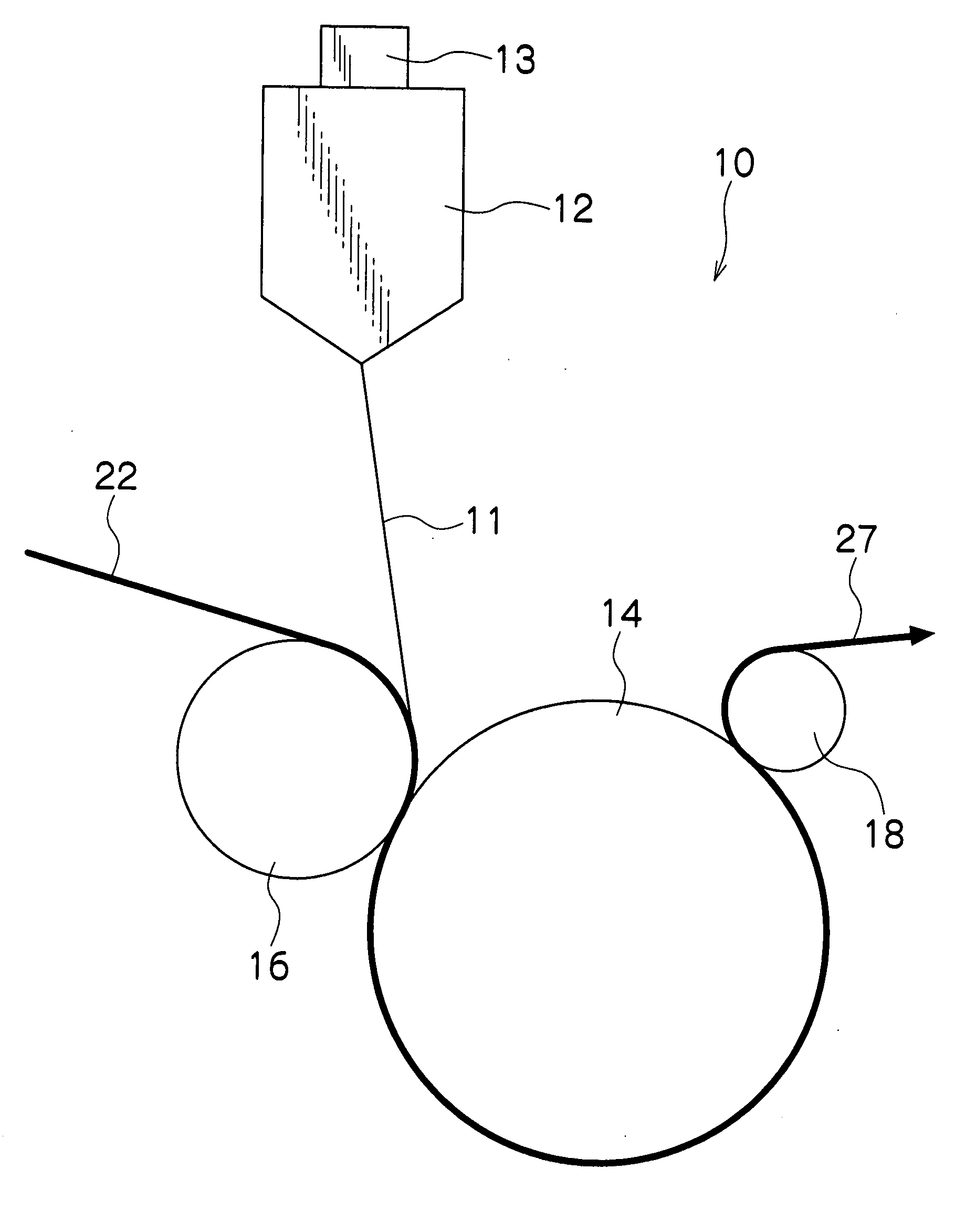

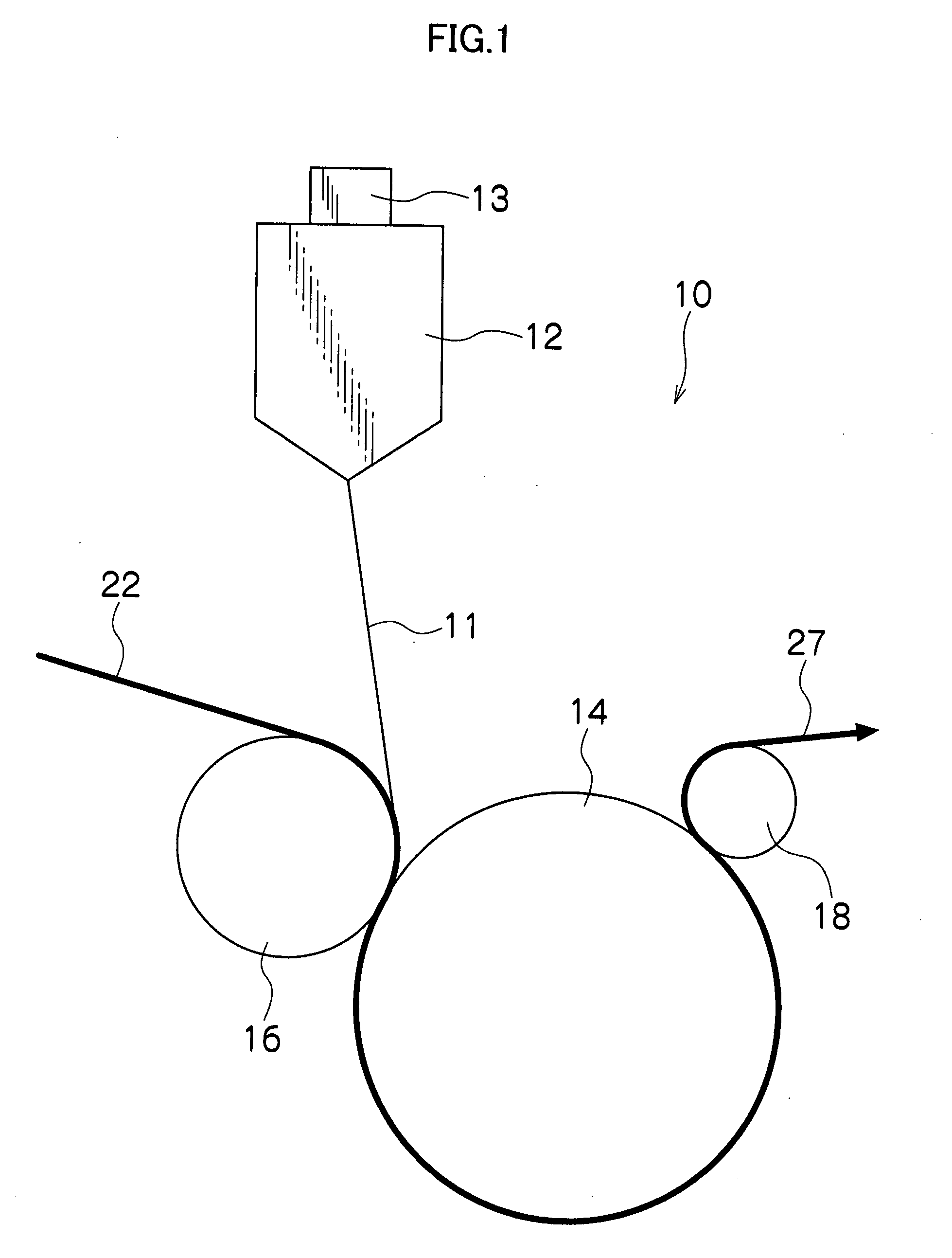

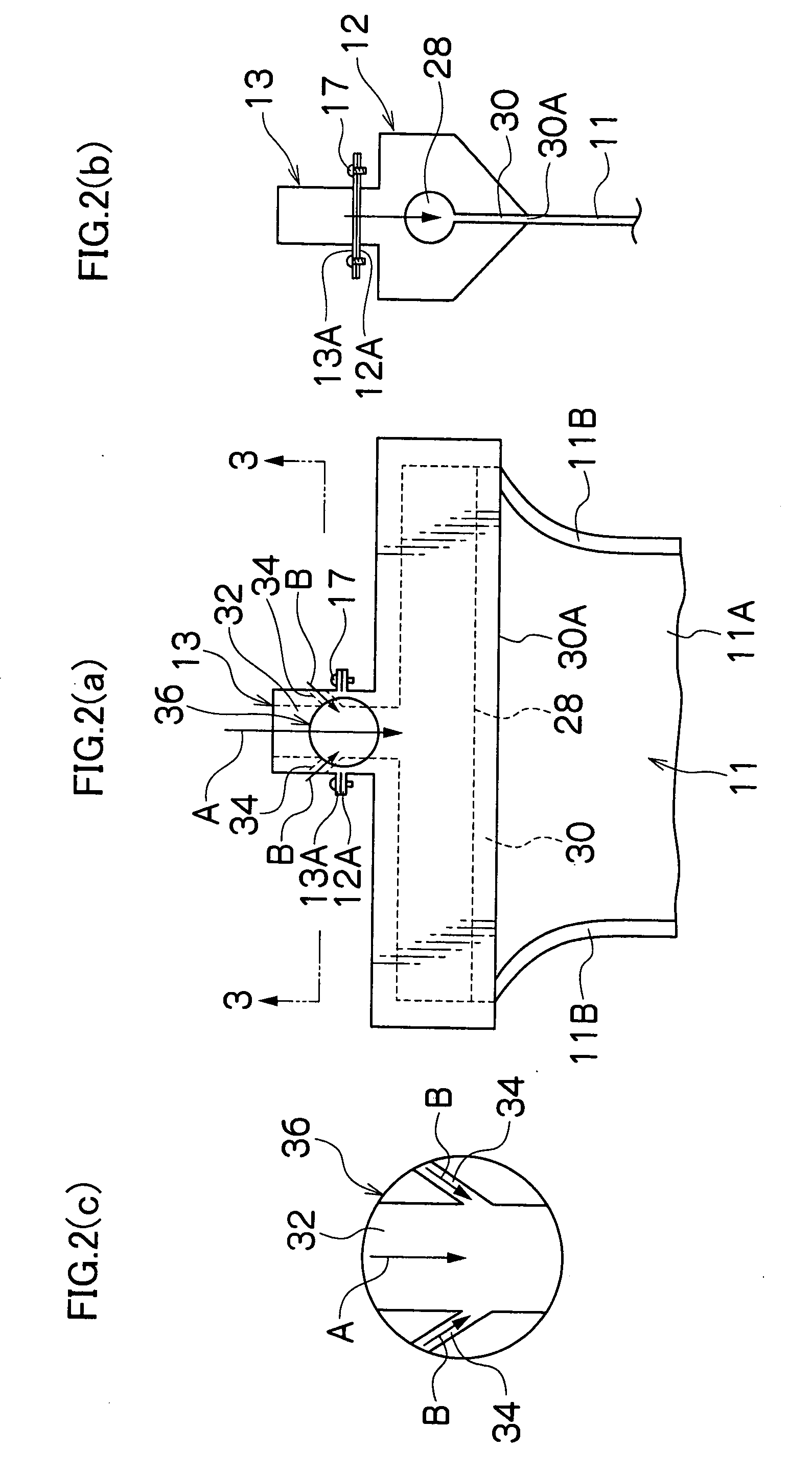

Method and apparatus for forming resin film

InactiveUS20040108621A1Preventing film separationAchieve recyclabilityConfectionerySweetmeatsMolten stateProduction rate

The apparatus is for forming a resin film from a resin for a middle portion to form a resin film main body of the resin film and a resin for edge portions to form both side edge portions in a crosswise direction of the resin film. The apparatus comprises: a feed block which includes a joining part where the resin for the middle portion in a molten state and the resin for the edge portions in a molten state are joined in such a manner as to enclose both side edges in the crosswise direction of the resin film main body with the resin for the edge portions; and an extruding die through which the joined resins are extruded to form the resin film. Thus, a method and apparatus for forming the resin film can avoid the inclusion of the resin for the middle portion in the trimmed-off selvages while preventing the film separation of the resins for the middle portion and for the edge portions, and therefore, increase the recyclability and the productivity of the resin film.

Owner:FUJIFILM CORP

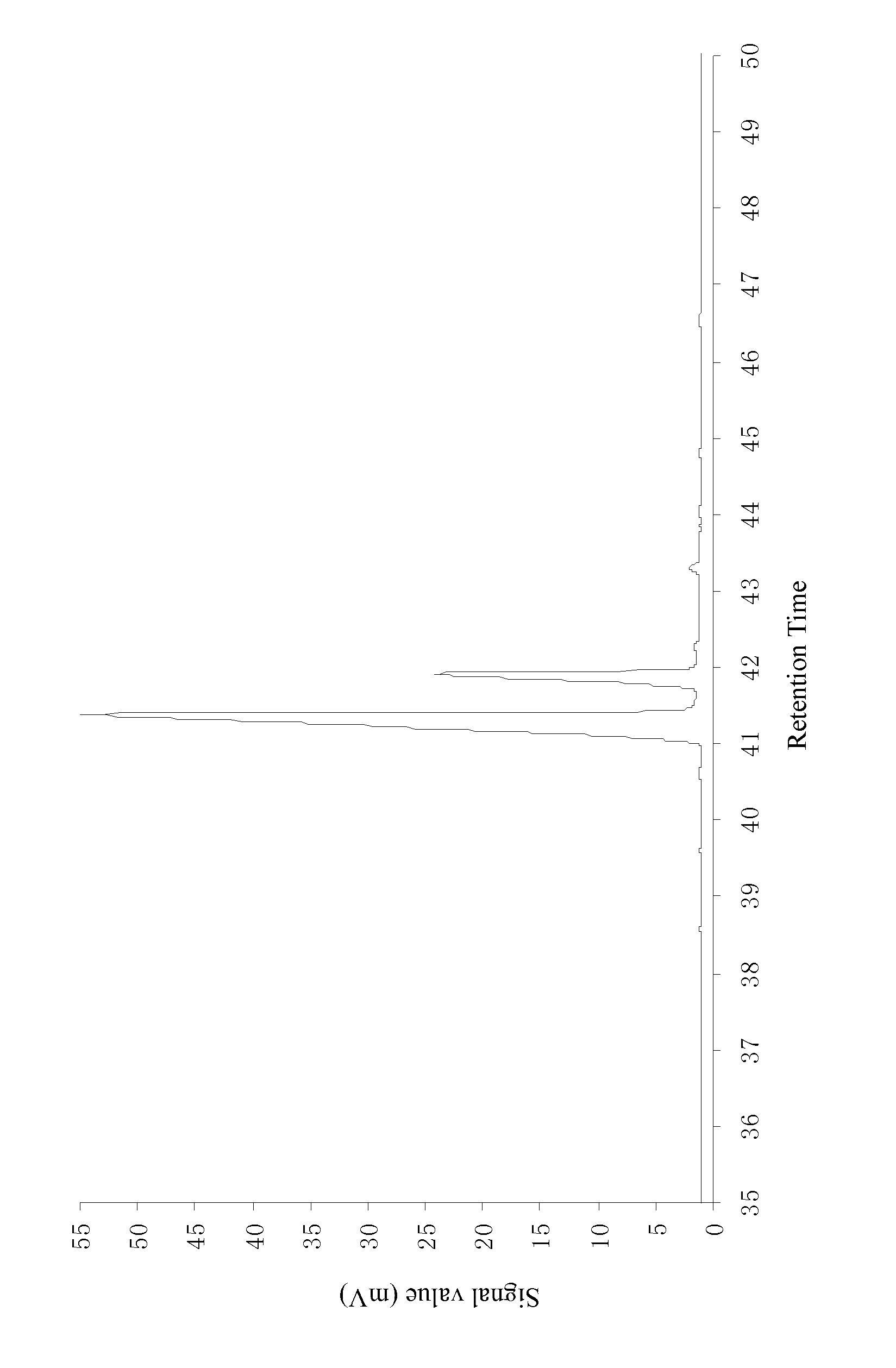

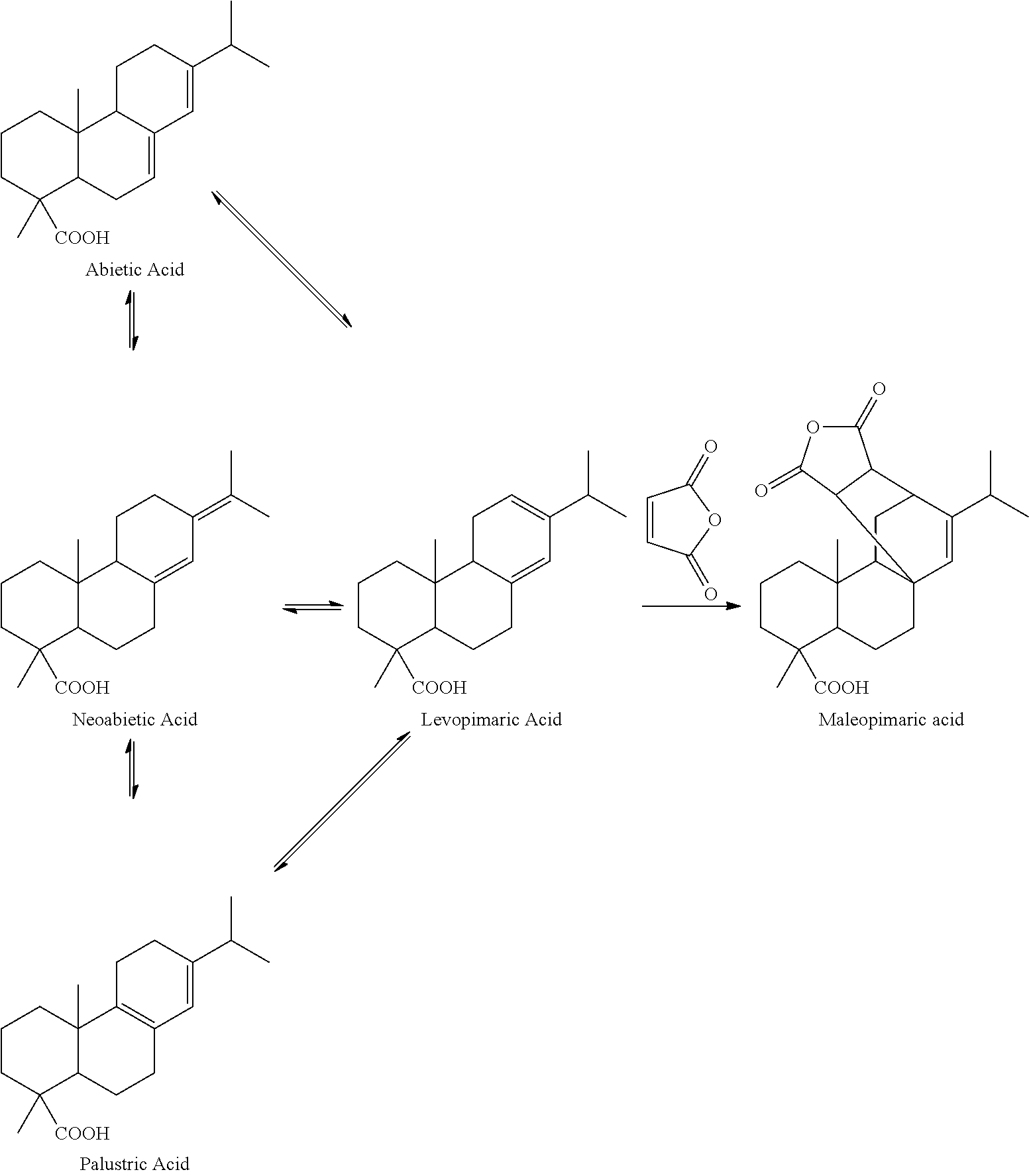

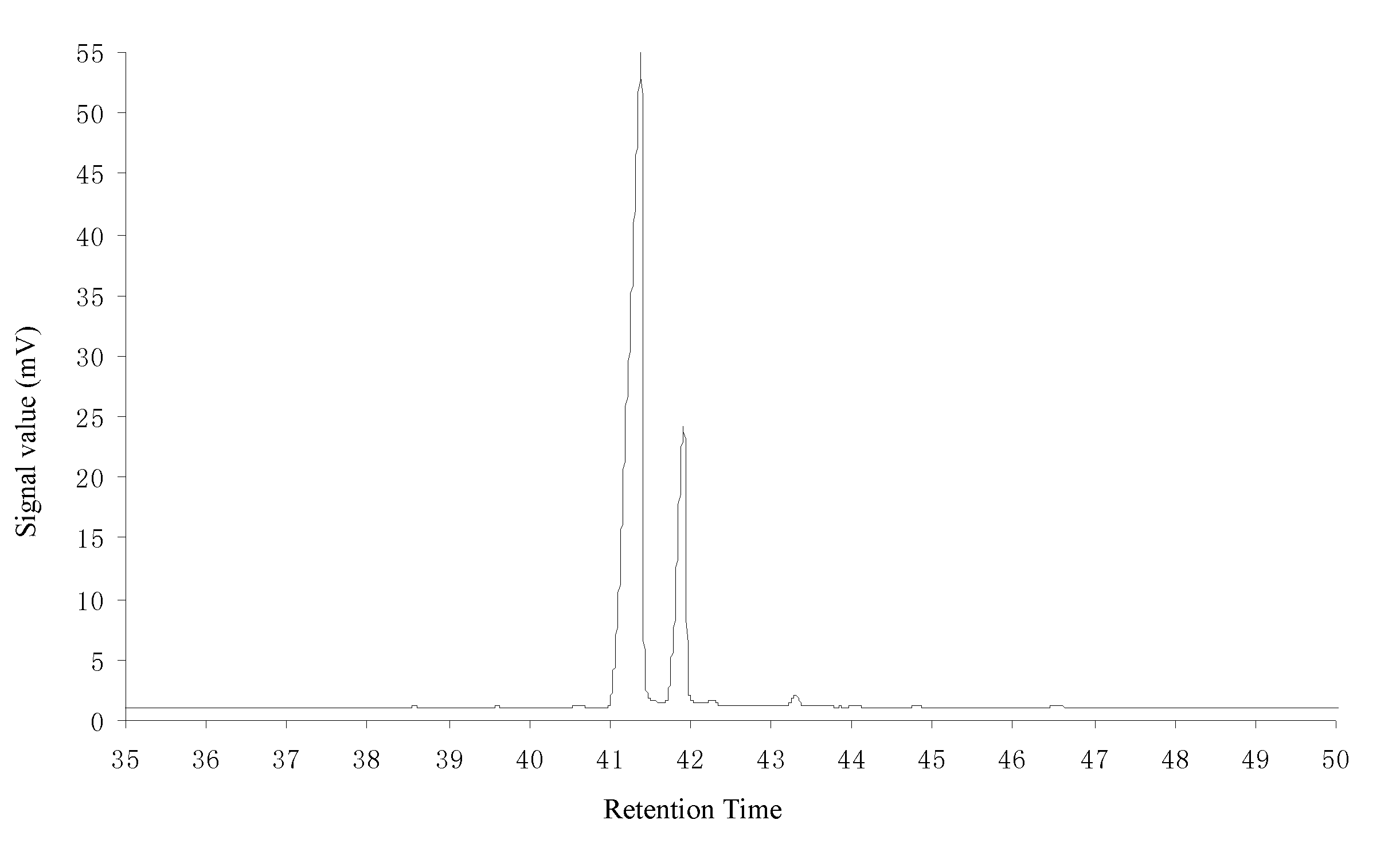

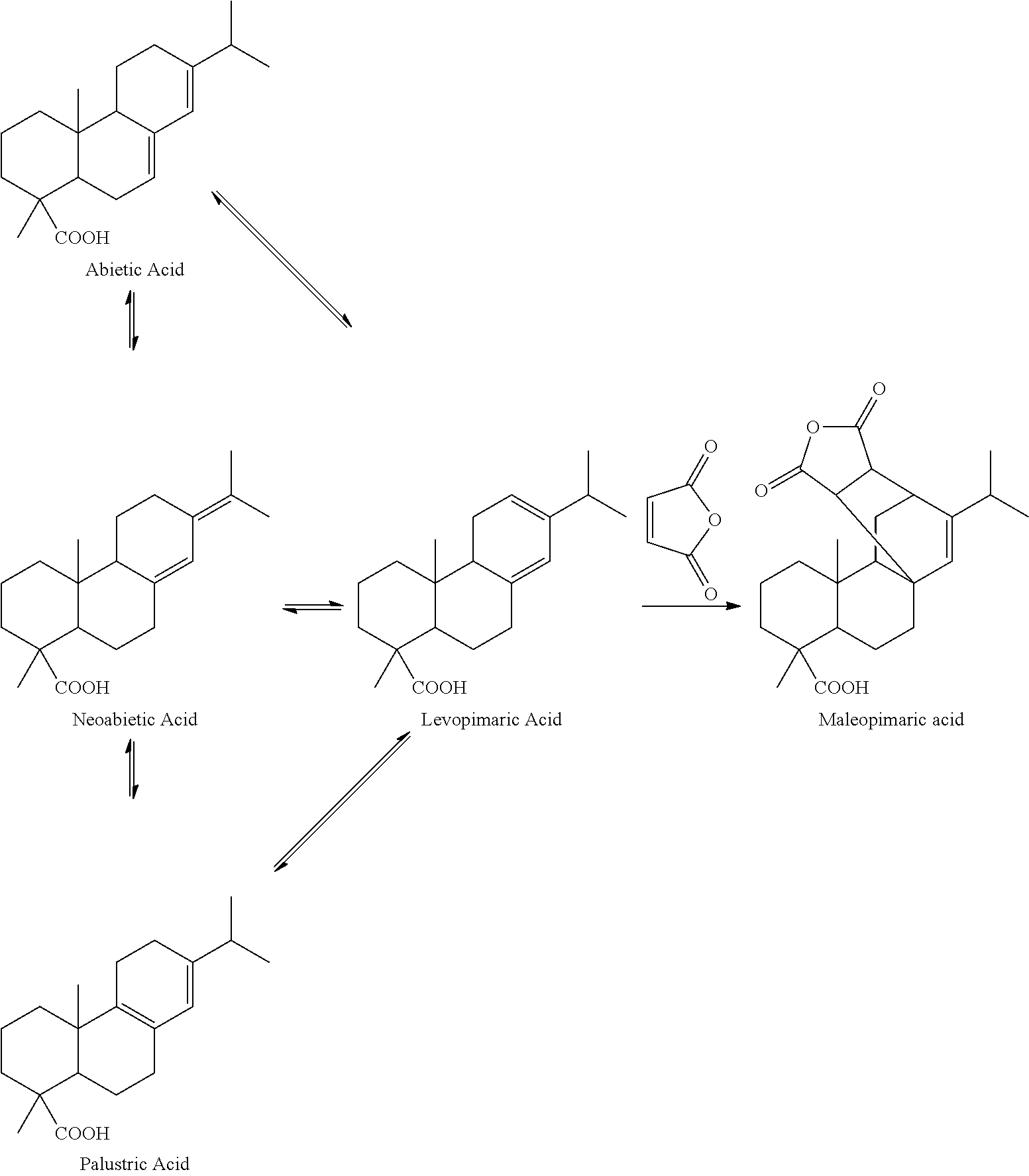

Preparation method of pimaric acid type resin acid

InactiveUS20120004390A1Increase temperatureYield andOrganic compound preparationNatural resin chemical modificationBottleSolvent

A method for preparing pimaric acid type resin acids includes the following steps: step (1) adding refined resin acid, turpentine, or rosin along with maleic anhydride at a mass ratio of 1:0.3-1.5 into a reaction bottle, dissolving the ingredients into a C1-C10 lower fatty acid solvent, the mass ratio of the C1-C10 low fatty acid to refined resin acid is 0.05-30:1, then carrying out additional reaction by heating directly or with assistance of a microwave, subsequently cooling, crystallizing, filtering, and washing; and step (2) combining the filtrates collected in step (1), stripping the solvent by vacuum distillation to obtain pimaric acid type resin acid coarse product, dissolving the resulting coarse product in NaOH aqueous solution to prepare aqueous solution of pimaric acid type resin acid salt, adjusting the pH level to 6-14 with a mineral acid or an organic acid while stirring, and either directly purifying or acidifying followed by purifying, the resulting precipitation to obtain the final product. The method has the characteristics of high yield, high product content, low cost, and low environmental pollution.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

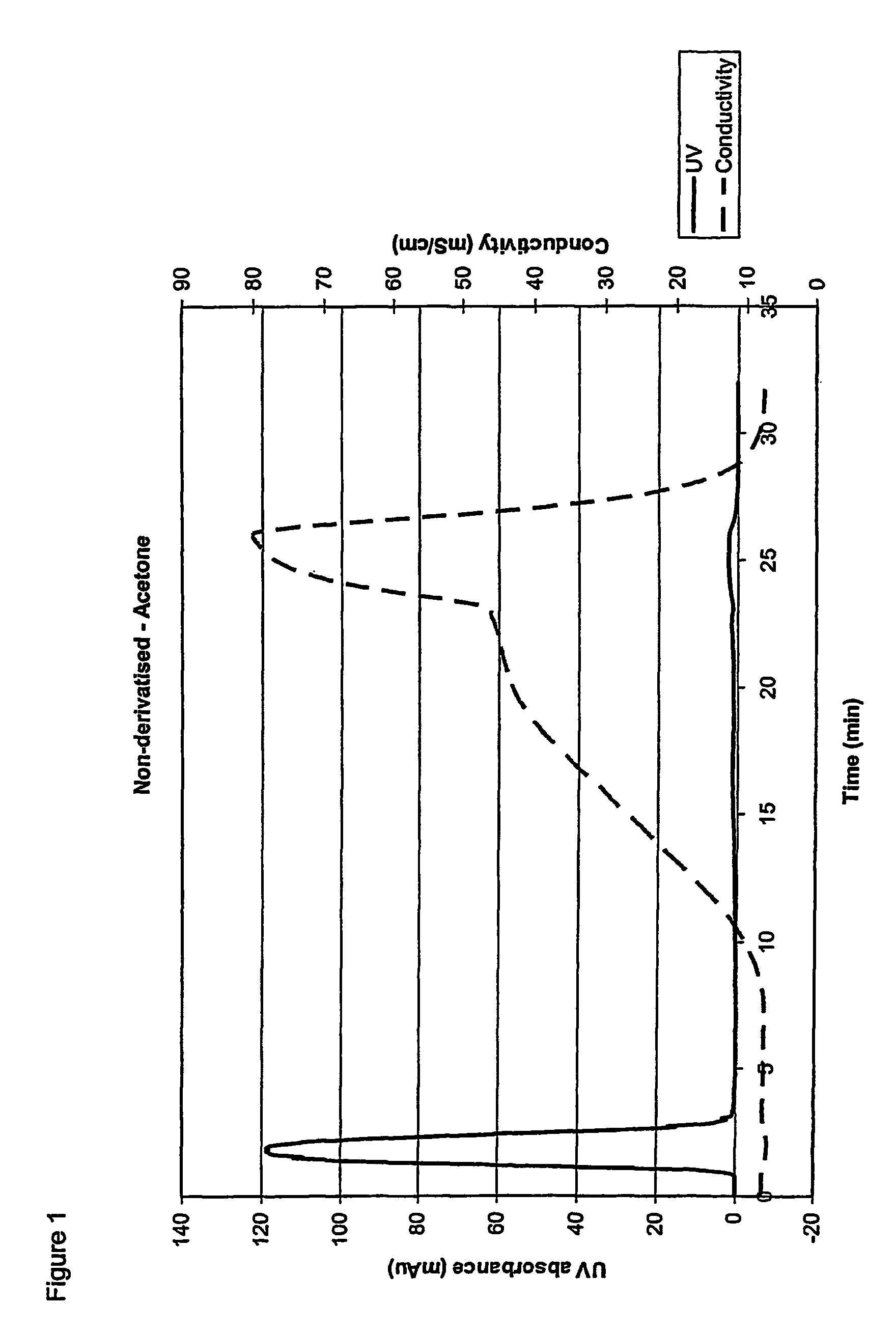

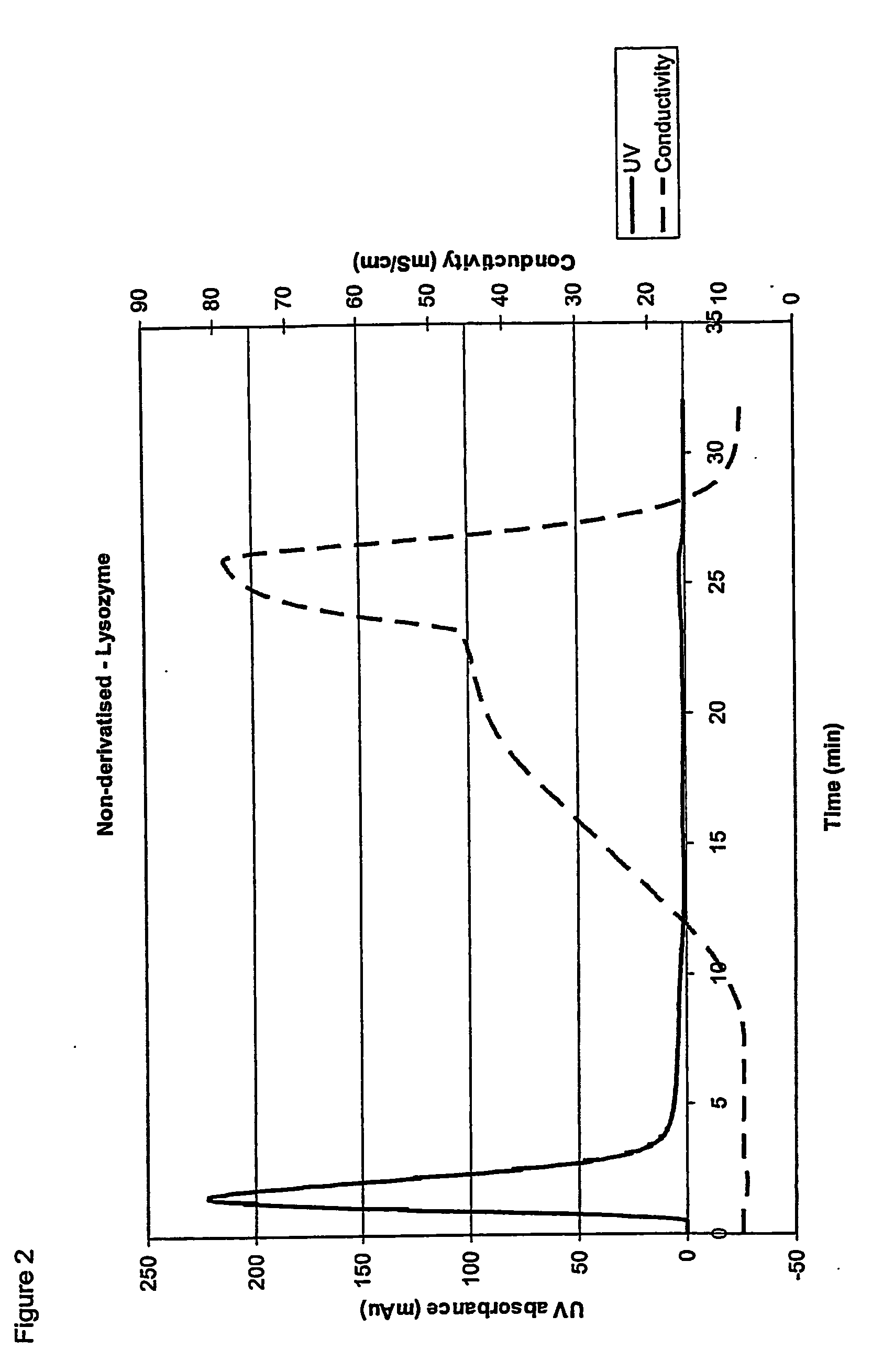

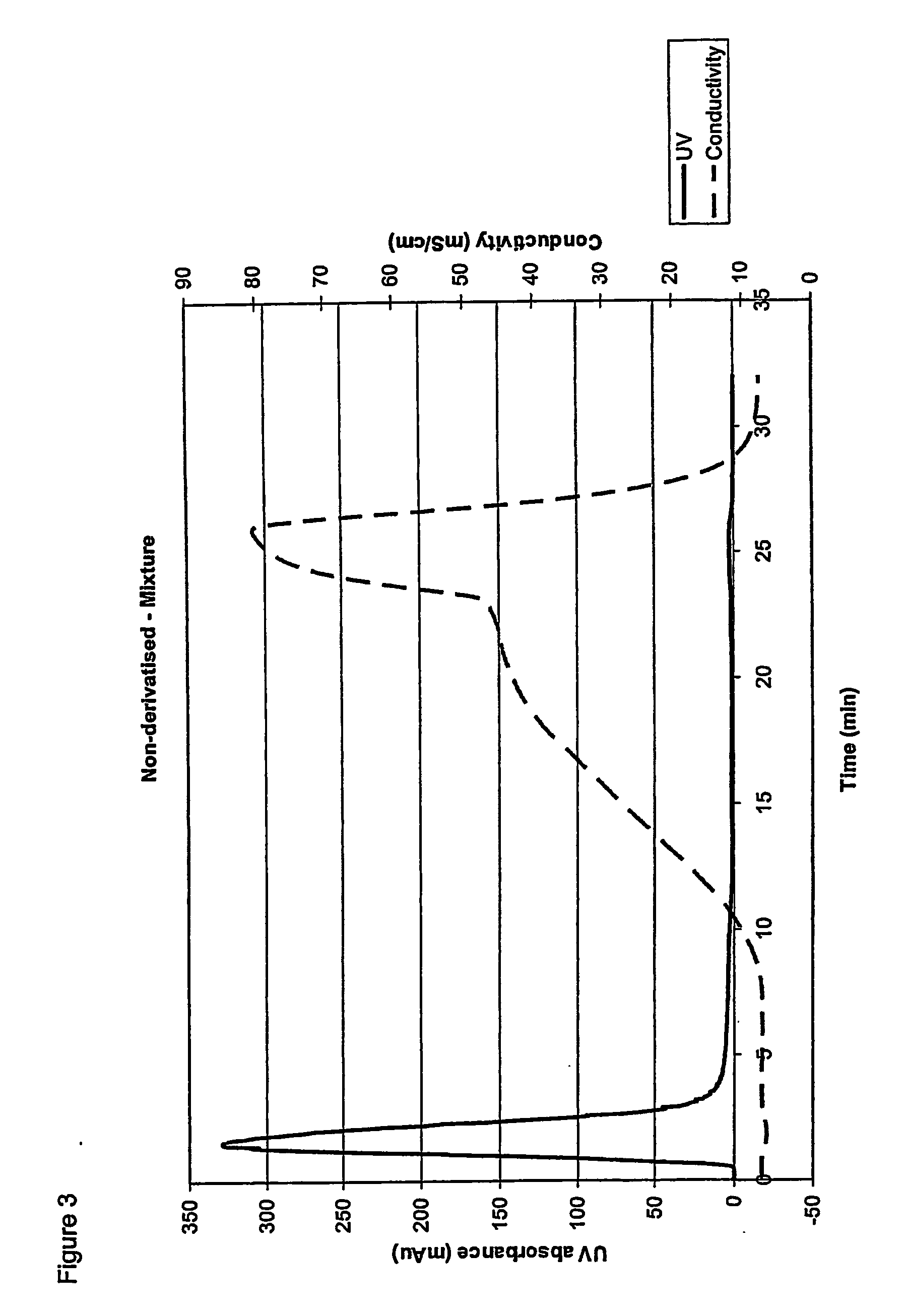

Separation Methods

InactiveUS20080029455A1FunctionalYield andCation exchanger materialsOrganic anion exchangersStationary phaseChromatographic separation

A method for chromatographic separation of a molecule, wherein a mobile phase and a charged stationary phase are present and a charged amphipathic sugar polymer(s) is employed to modify the hydrophobic interaction between the molecule and said charged stationary phase.

Owner:EXPEDON LTD

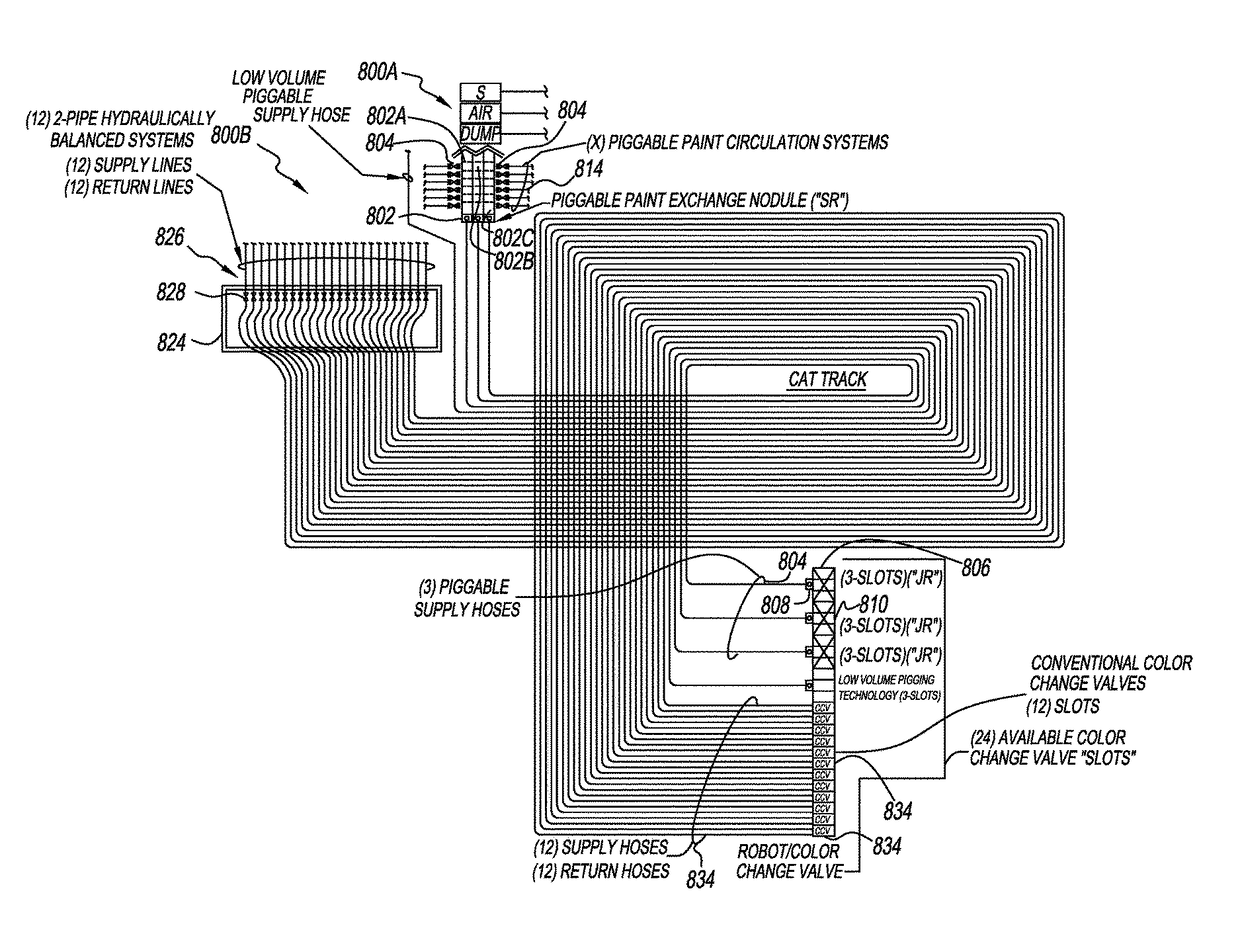

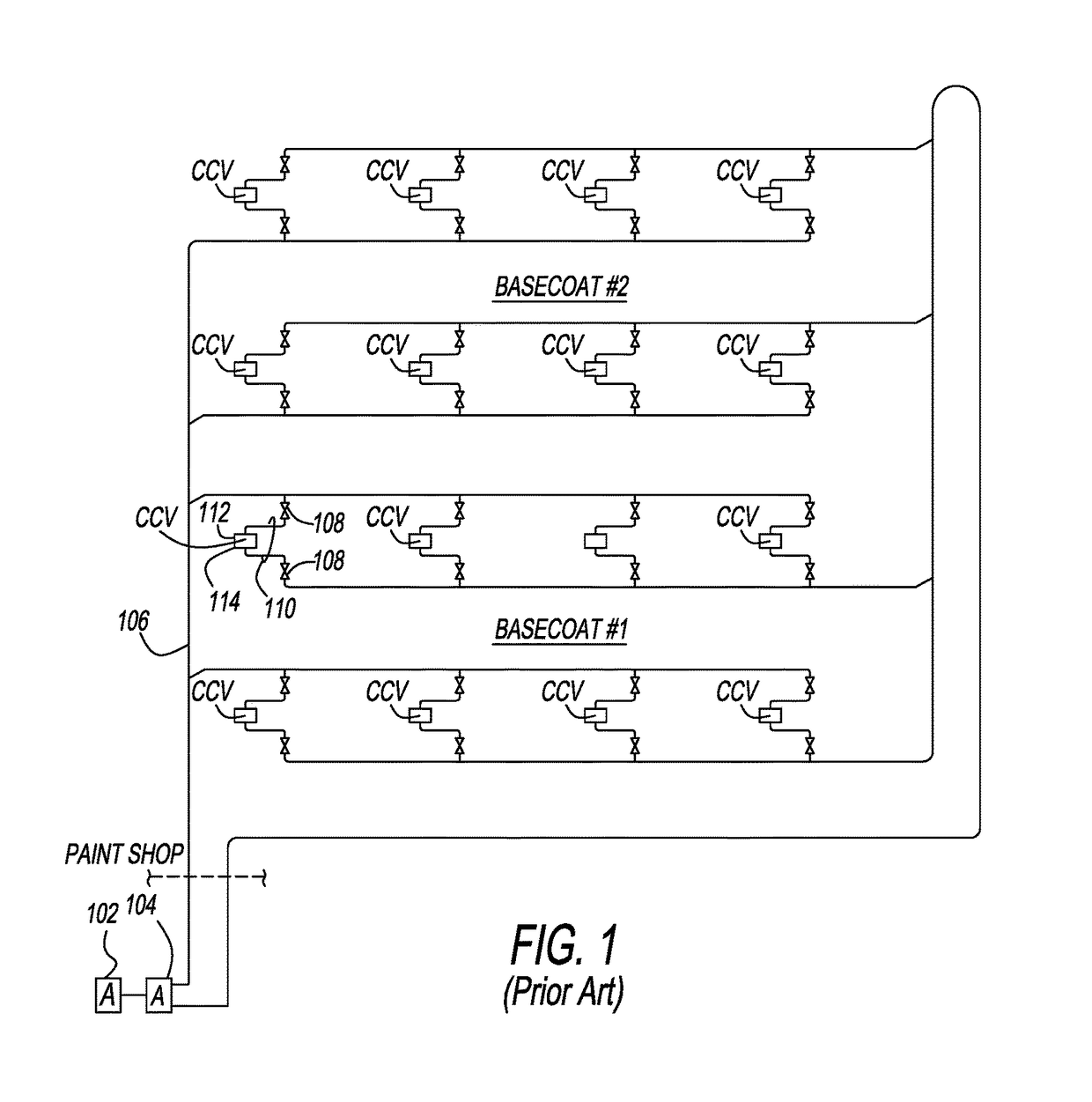

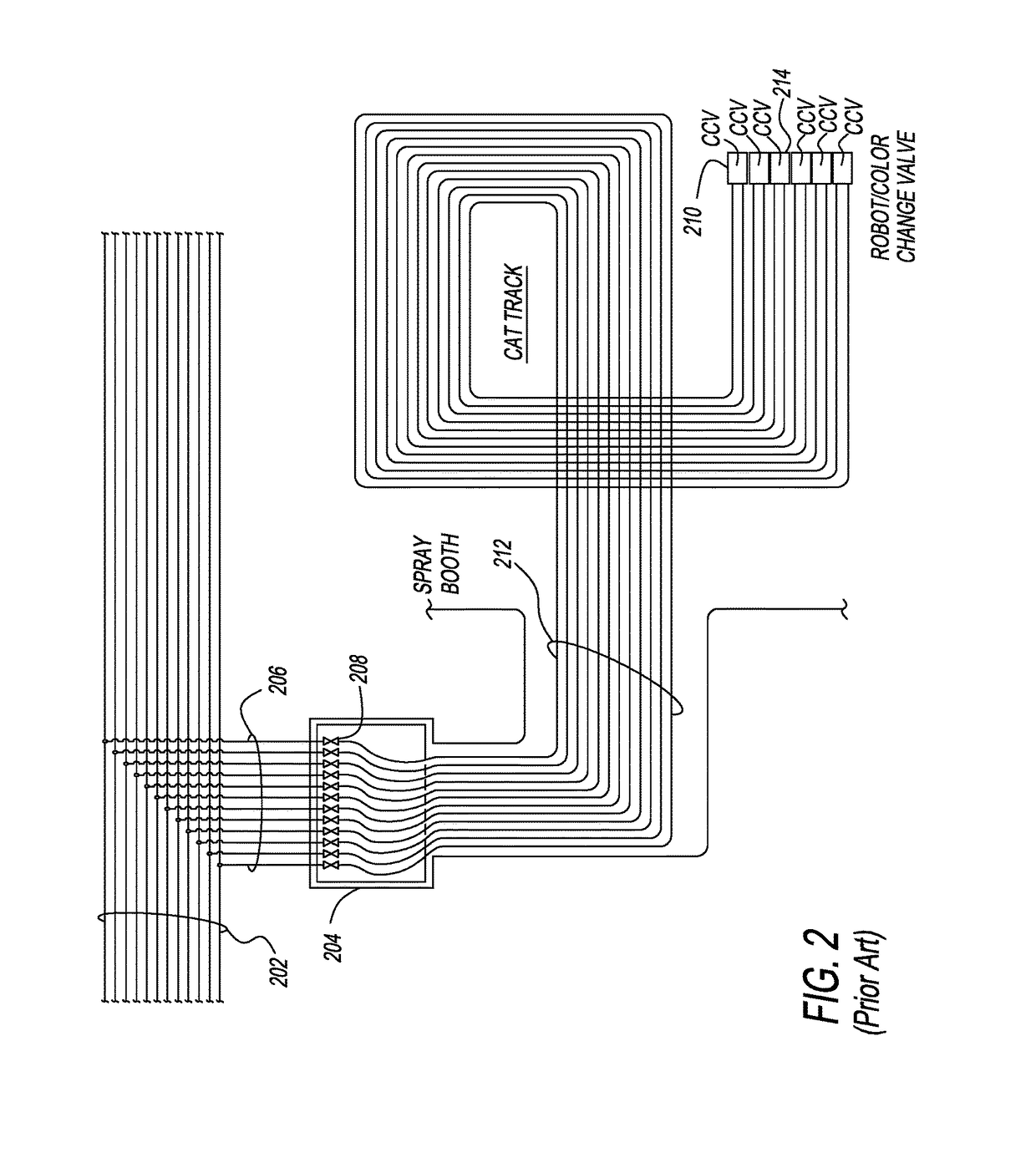

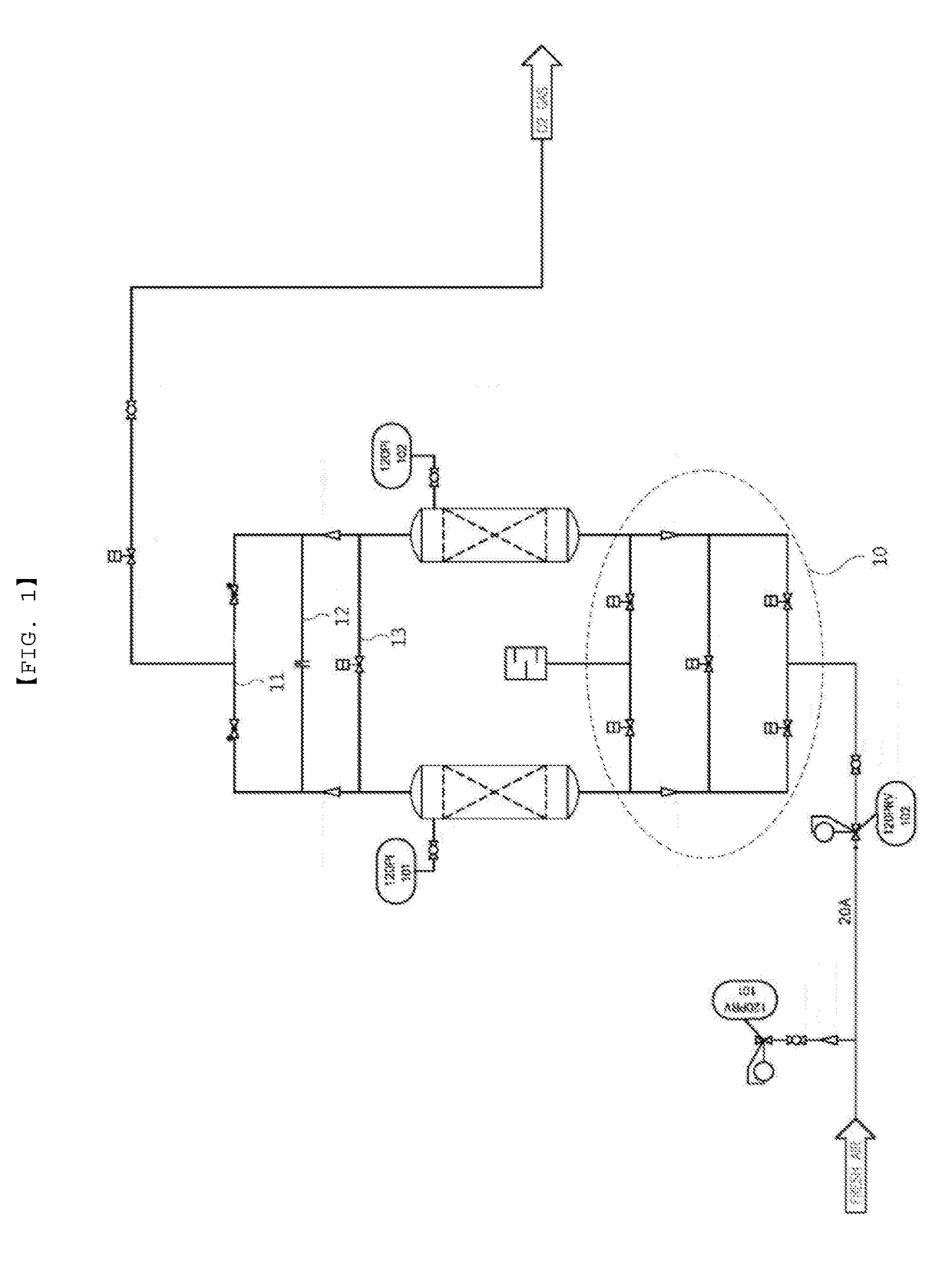

Liquid distribution system and method

ActiveUS20170197224A1Reduce operating costsReduce maintenanceLiquid surface applicatorsLiquid spraying apparatusLiquid ChangeDistribution system

A liquid (e.g., paint) distribution system comprising: at least one liquid reservoir; at least one liquid exchange assembly, wherein the liquid exchange assembly comprises at least one liquid exchange module; a plurality of liquid circulation lines disposed between the liquid reservoir and at least one liquid exchange module, wherein each the liquid circulation line supplies at least one liquid to the liquid exchange module; at least one liquid change valve module; and at least one liquid supply line in fluid communication between the liquid exchange module and the liquid change valve module. The liquid exchange module is configured such that the number of the liquid supply lines in fluid communication between the liquid exchange module and the liquid change valve module is less than the number of liquid circulation lines from the liquid reservoir to the liquid exchange module.

Owner:J&R DESIGN SYST INC

Methods, compositions and systems for biosynthetic bio-production of 1,4 butanediol

InactiveUS20140120595A1Improve toleranceYield andBioreactor/fermenter combinationsBiological substance pretreatments1,4-ButanediolMicroorganism

Owner:CARGILL INC

Additive to maximize GLP and propene suitable for use in low-severity operations of a fluid catalytic cracking unit and its preparatory process

ActiveUS7691768B2Reduce severityMaintenanceCatalytic crackingMolecular sieve catalystsReaction temperaturePhysical chemistry

A process for the preparation and modification of additives, with a zeolite base and a high silica alumina ratio (SAR) like the ZSM-5, to increase the yield of propene and LPG in low severity FCC operations, that seeks to maximize the production of medium-distillates with low aromaticity and to minimize molecular cracking in the LCO range. The additives involved guarantee an increase in light olefin yields without altering the yield or the quality of the LCO produced. The innovative process includes surprising actions from rare earths (RE) on the active sites of zeolite, that at once partially block their pores and, in this way, make molecular cracking in the medium-distillate range difficult, which preferably occur at low reaction temperatures and keeps the remaining sites quite active. These sites are sufficiently active to crack smaller molecules in the gasoline range, guaranteeing an overall increase in light olefins and allowing the additive involved to be used industrially in operations to maximize medium-distillates in an FCC unit. This new additive may be obtained by modifying any commercial ZSM-5 zeolite additive.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Substrate processing method and method of manufacturing crystalline silicon carbide (SIC) substrate

ActiveUS8187958B2Reduce surface roughnessIncrease productionSemiconductor/solid-state device manufacturingSemiconductor devicesCarbideSurface roughness

The present invention provides a method of processing a substrate and a method of manufacturing a silicon carbide (SiC) substrate in which, when annealing processing is performed on a crystalline silicon carbide (SiC) substrate, the occurrence of surface roughness is suppressed. A substrate processing method according to an embodiment of the present invention includes a step of performing plasma irradiation on a single crystal silicon carbide (SiC) substrate (1) and a step of performing high temperature heating processing on the single crystal silicon carbide (SiC) substrate (1) in which the plasma irradiation is performed.

Owner:CANON ANELVA CORP

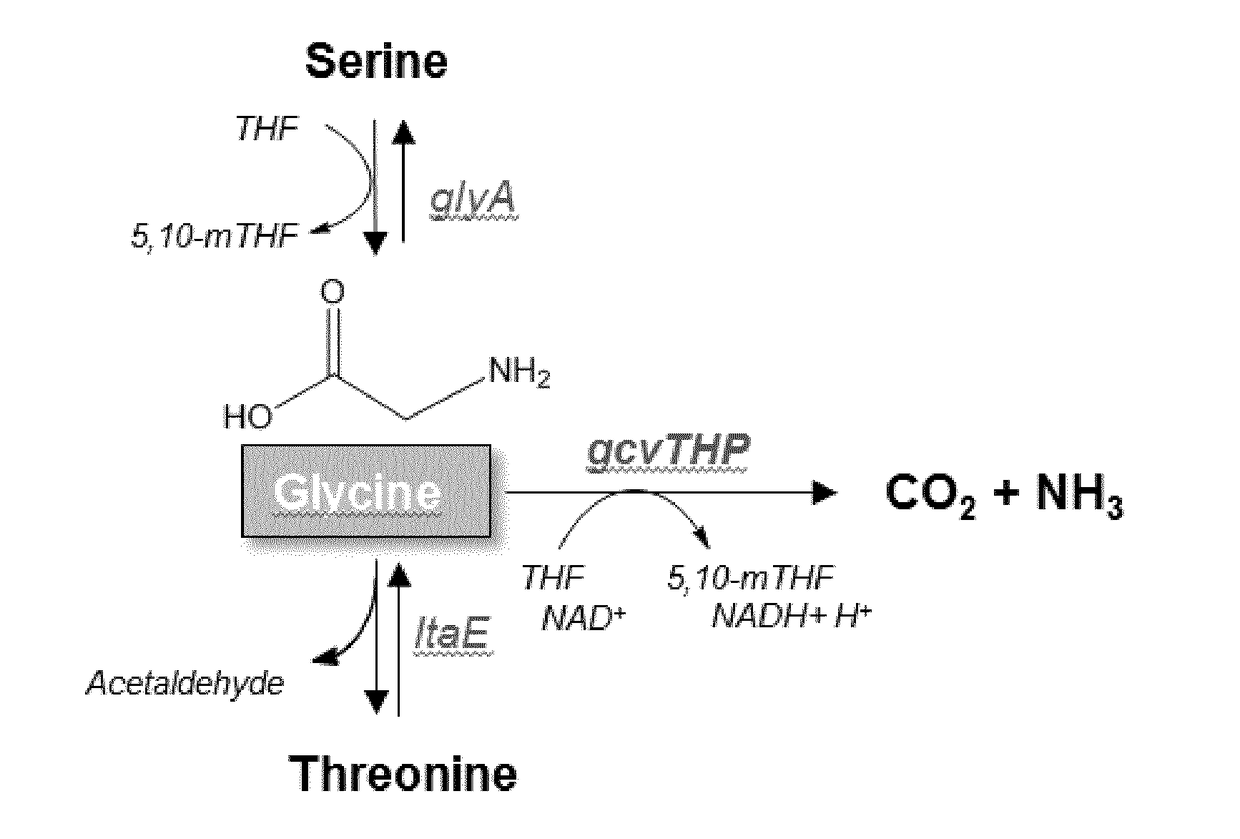

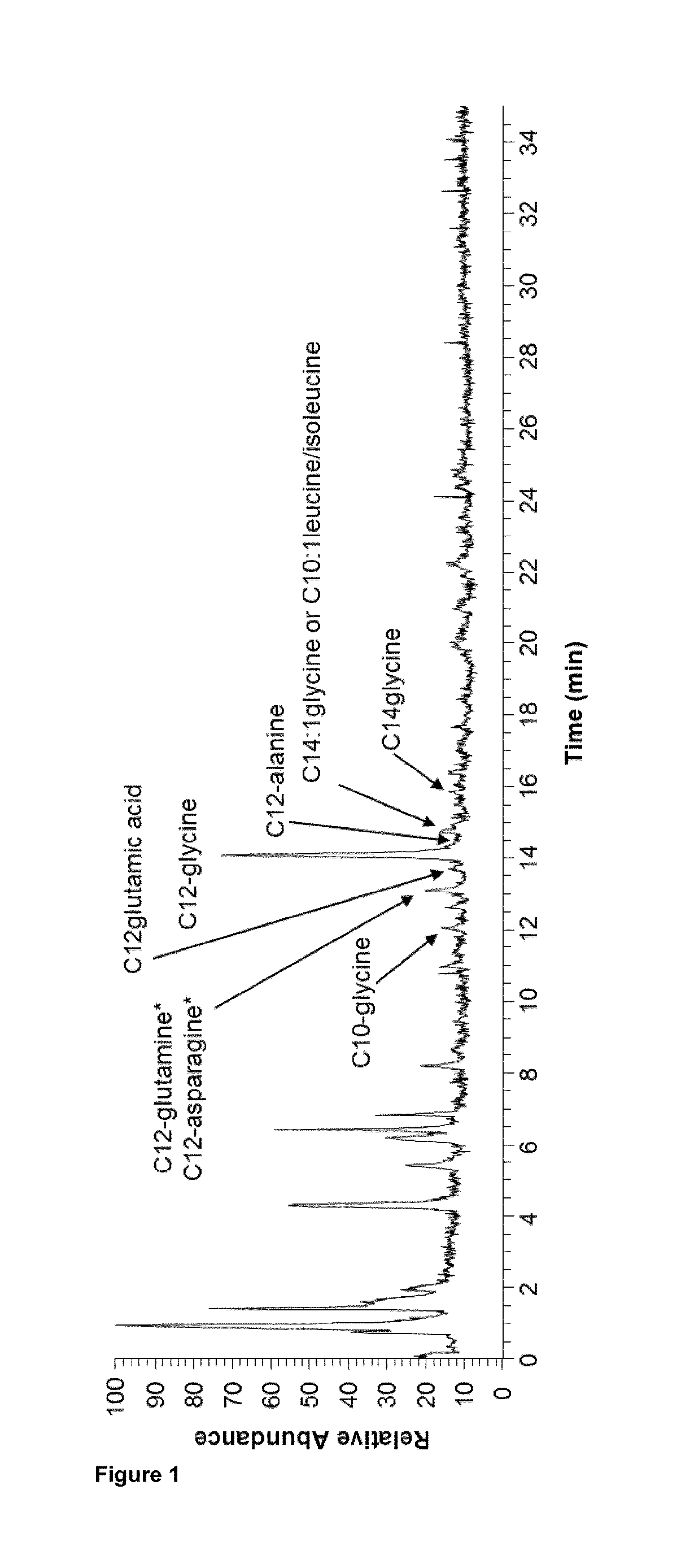

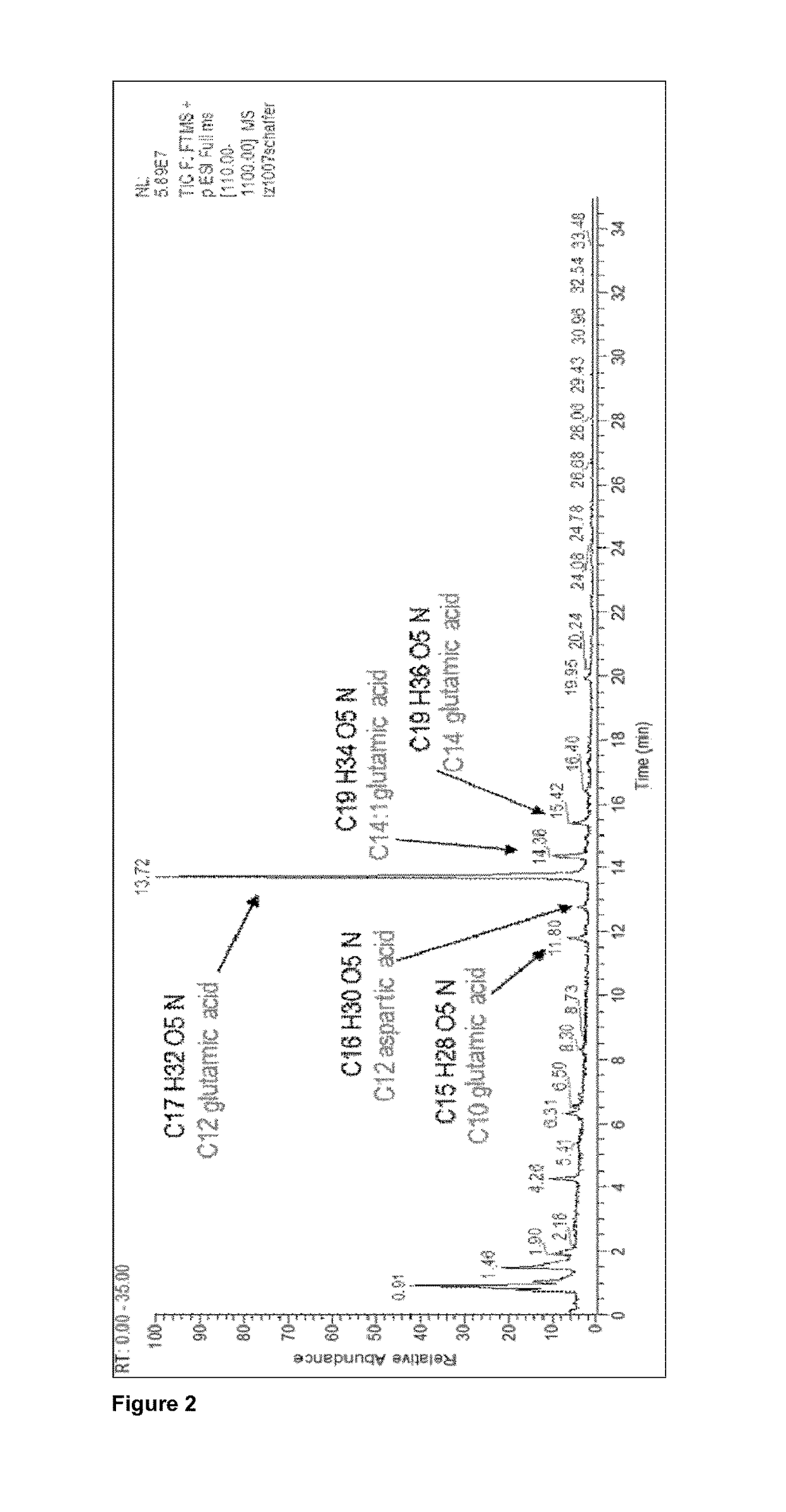

Byosynthetic Production of Acyl Amino Acids

InactiveUS20170130248A1PurityYield andLigasesAcyltransferasesAcyl Coenzyme A SynthetasesAcyl-CoA synthetase

The present invention relates to a cell for producing acyl glycinates wherein the cell is genetically modified to compriseat least a first genetic mutation that increases the expression relative to the wild type cell of an amino acid-N-acyl-transferase,at least a second genetic mutation that increases the expression relative to the wild type cell of an acyl-CoA synthetase, andat least a third genetic mutation that decreases the expression relative to the wild type cell of at least one enzyme selected from the group consisting of an enzyme of the glycine cleavage system, glycine hydroxymethyltransferase (GlyA) and threonine aldolase (LtaE).

Owner:EVONIK DEGUSSA GMBH

Composition and methods for improving the production of fermentation operations

Methods and compositions for improving the production of ethanol by a Saccharomyces spp. yeast in a fermentation medium are provided, where the method comprises adding to the fermentation medium an emulsion comprising a monoterpene and a surfactant in an amount sufficient to improve the production of ethanol.

Owner:POLYMER VENTURES

Composition and methods for improving the production of fermentation operations

Methods and compositions for improving the production of ethanol by a microorganism in a fermentation medium are provided, where the method comprises adding to the fermentation medium an emulsion comprising a monoterpene and a surfactant in an amount sufficient to improve the production of ethanol.

Owner:POLYMER VENTURES

Method for synthesizing aluminum nitride

A method for synthesizing aluminum nitride is disclosed, wherein an ignition agent is formed by mixing an azide powder (such as sodium azide; NaN3) and aluminum powder, and is paved on an ignition portion of a reactant-containing body having a plurality of ratios of aluminum to a diluent, wherein the content of the diluent is gradually increased in accordance with the propagation direction of combustion wave generated in the combustion synthesis process. The method for synthesizing aluminum nitride is to ignite the ignition agent located in the ignition portion of the reactant-containing body under an ambience in which the pressure is less than 1 atm, and to introduce nitrogen gas as the nitrogen source into the reaction chamber after ignition.

Owner:TAIYEN BIOTECH

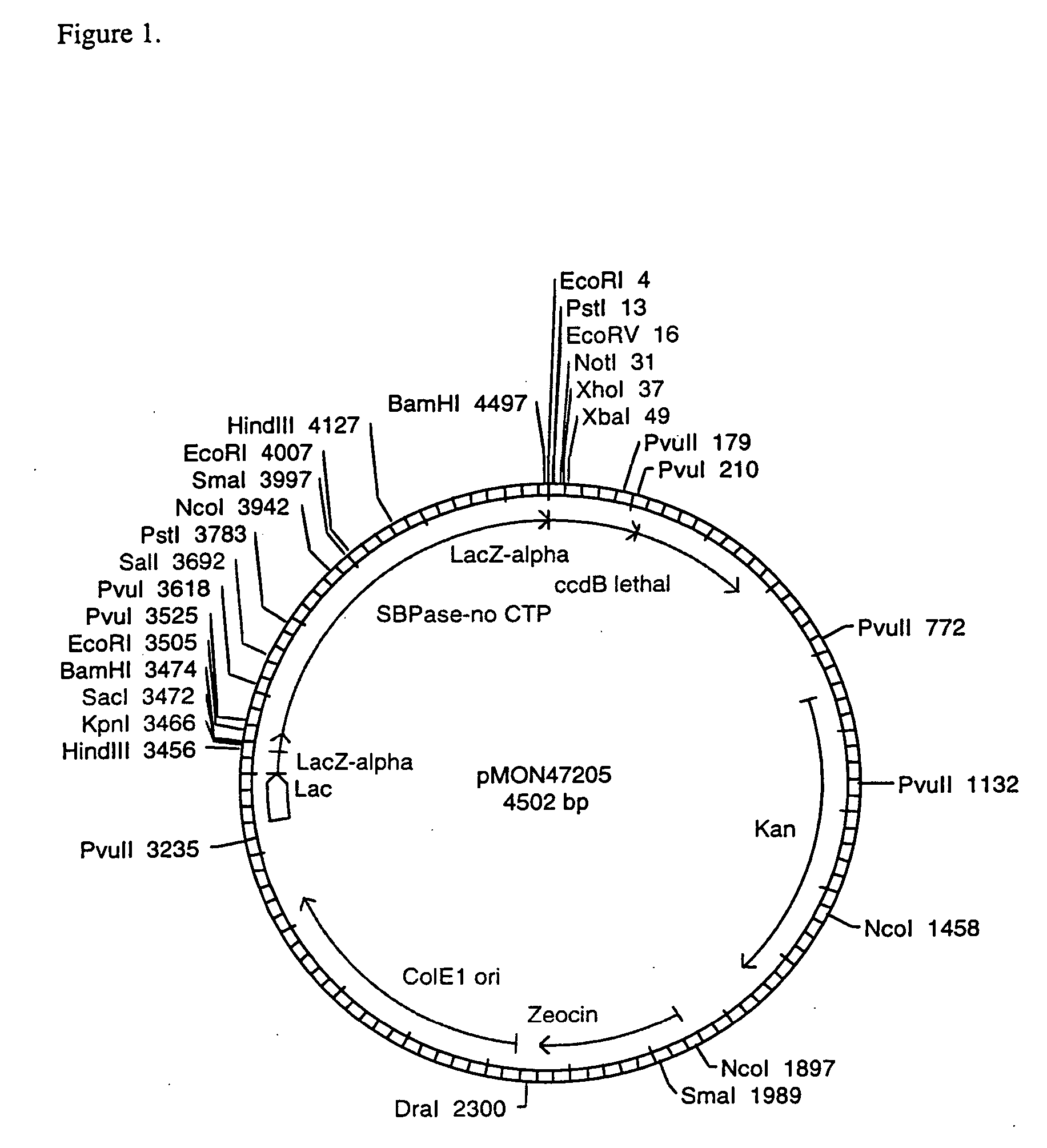

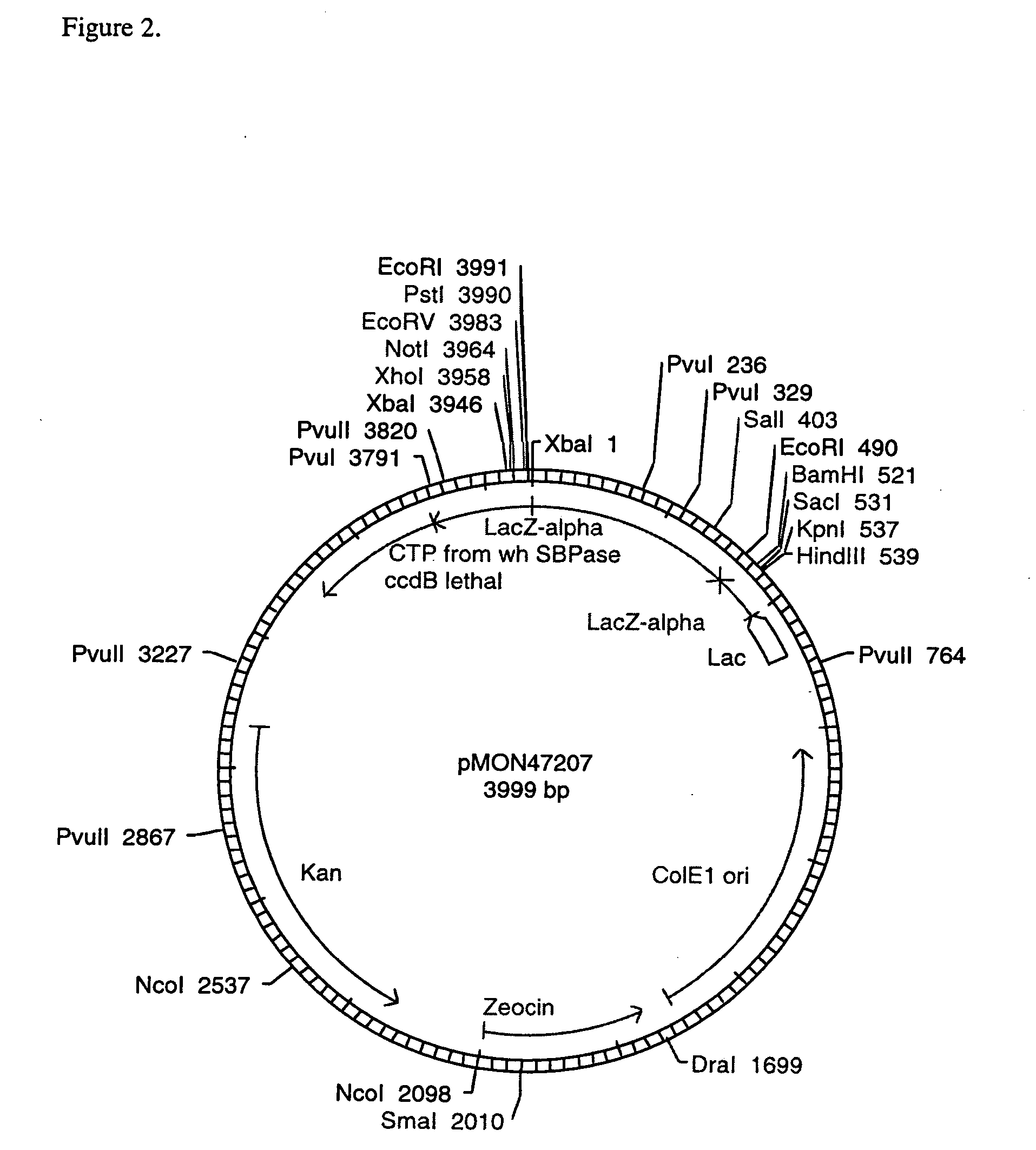

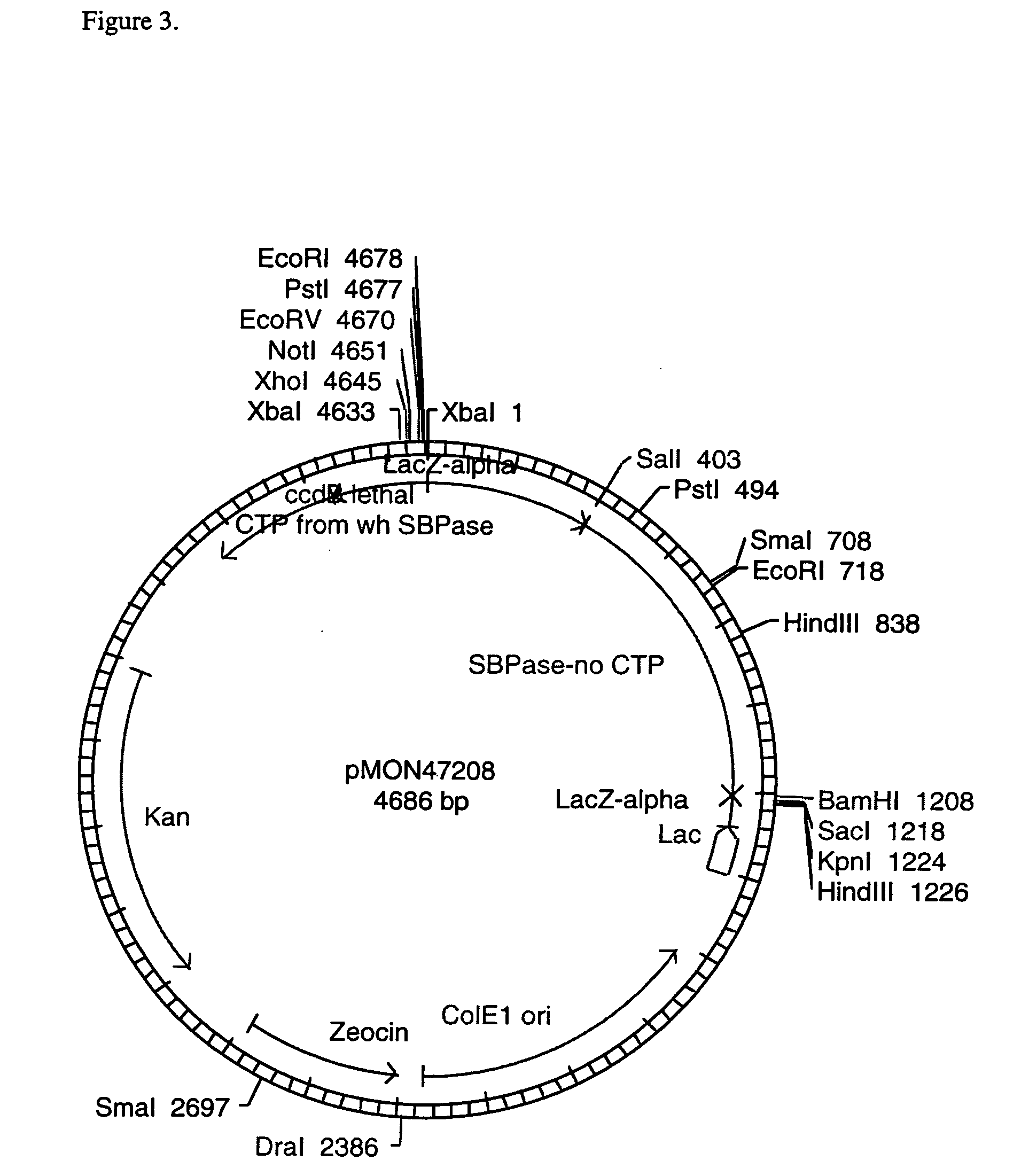

Expression of sedoheptulose 1,7 bisphosphatase in transgenic plants

InactiveUS20050005331A1Promote assimilationImproving carbon assimilation, storage and exportHydrolasesOther foreign material introduction processesSucroseSedoheptulose 7-phosphate

Sedoheptulose 1,7-bisphosphatase (SBPase) is an enzyme catalyzing the reaction converting sedoheptulose 1,7-bisphosphate into sedoheptulose 7-phosphate. This enzyme is located in the chloroplast in leaves and stems. Overexpression of SBPase in transgenic plants is provided to improve plant yield by increasing leaf starch biosynthetic ability in particular and sucrose production in general. Deregulated variants of the enzymes are also provided.

Owner:MONSANTO TECH LLC

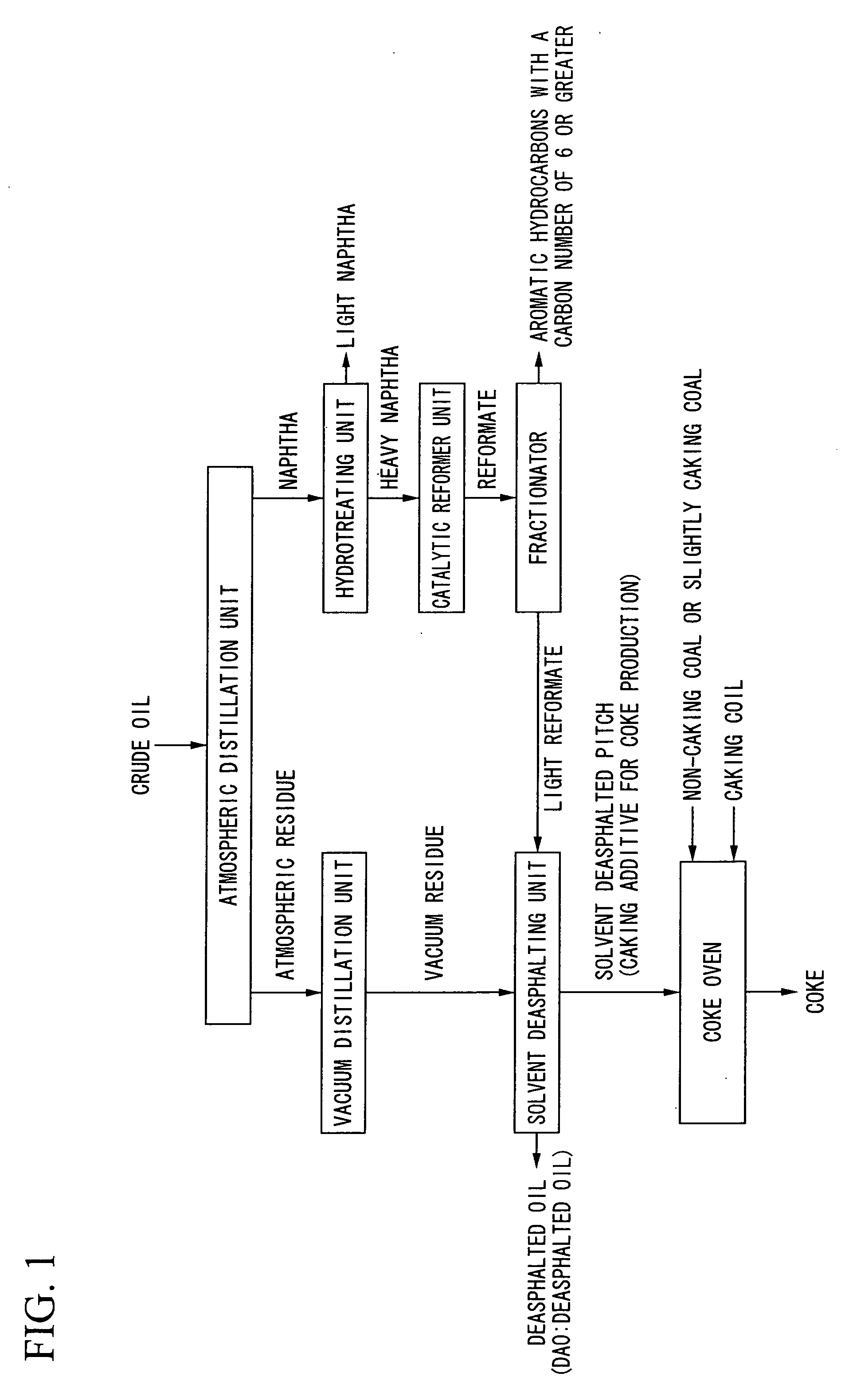

Process for producing caking additive for coke production and process for producing coke

ActiveUS20110284424A1Increase coke strengthFavorable caking additiveThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by distillationCatalytic reformingNaphtha

A process for producing a caking additive for coke production, the process including a step of extracting a solvent deasphalted pitch that can be used as a caking additive for coke production from a residue containing at least one of an atmospheric residue obtained by atmospheric distillation of a crude oil and a vacuum residue obtained by atmospheric distillation and vacuum distillation of a crude oil, wherein the extraction is performed using, as a solvent, a light reformate obtained by catalytic reforming a naphtha fraction that is fractionated from a crude oil by atmospheric distillation of the crude oil.

Owner:MITSUBISHI CHEM CORP

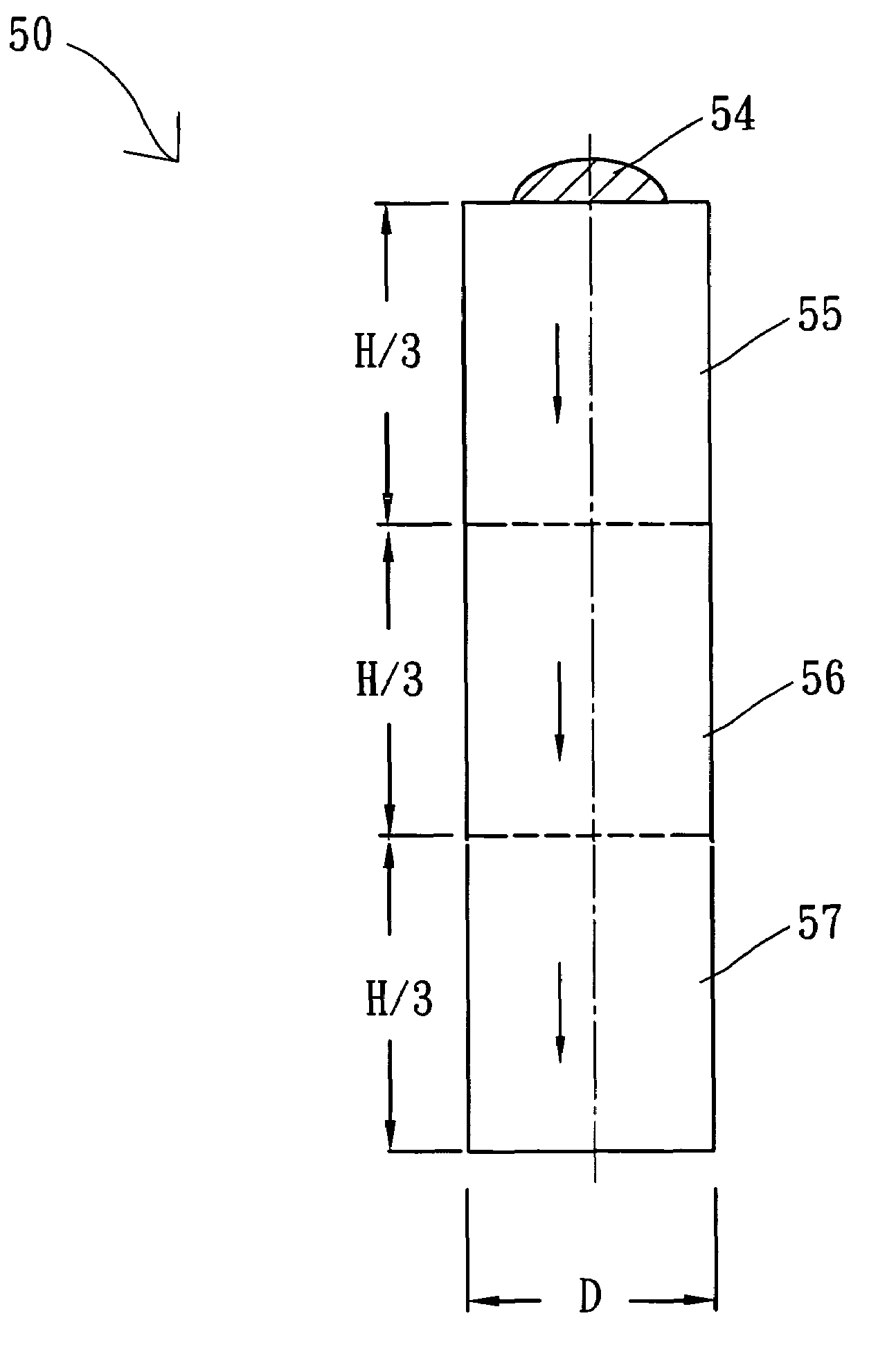

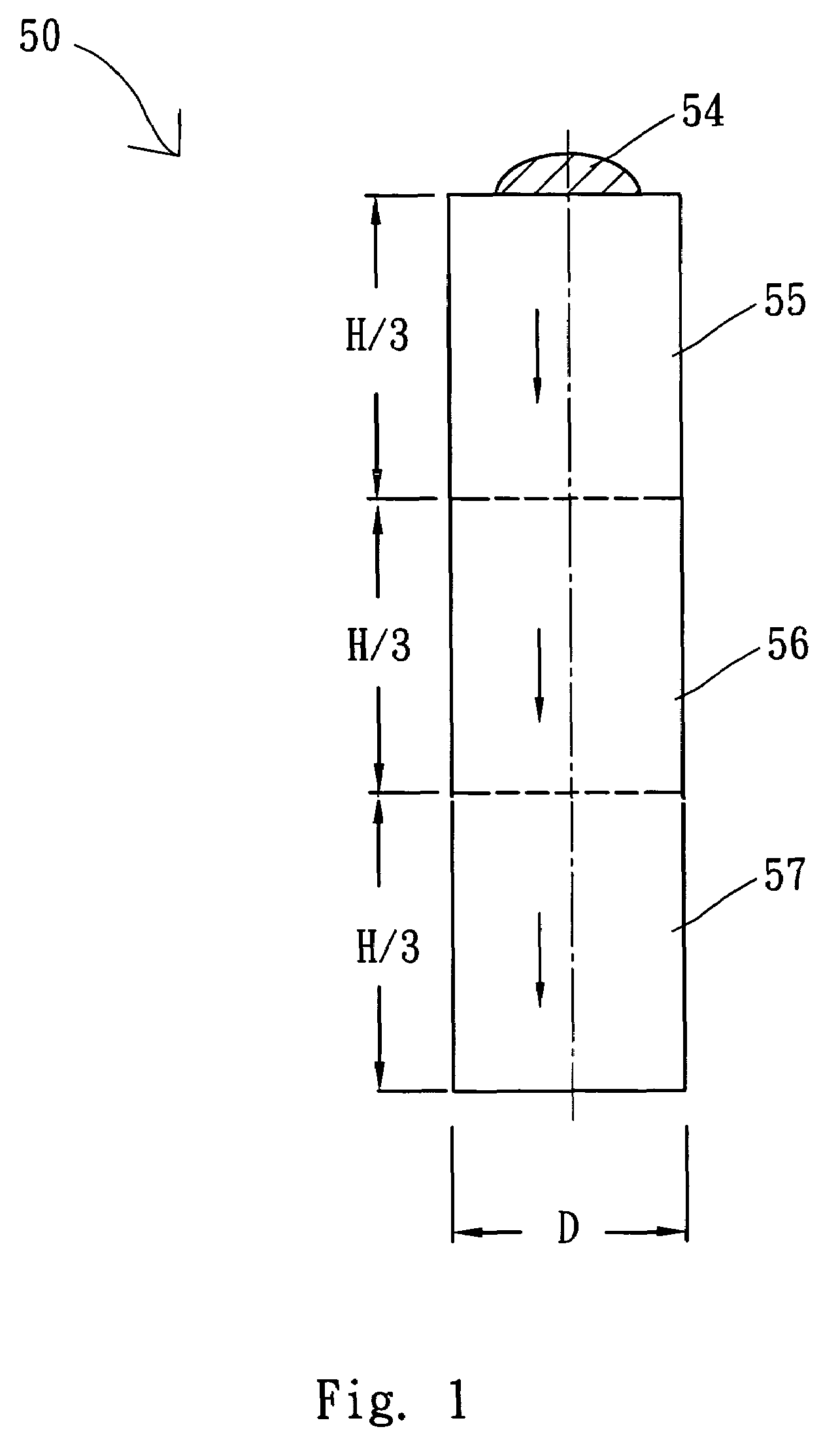

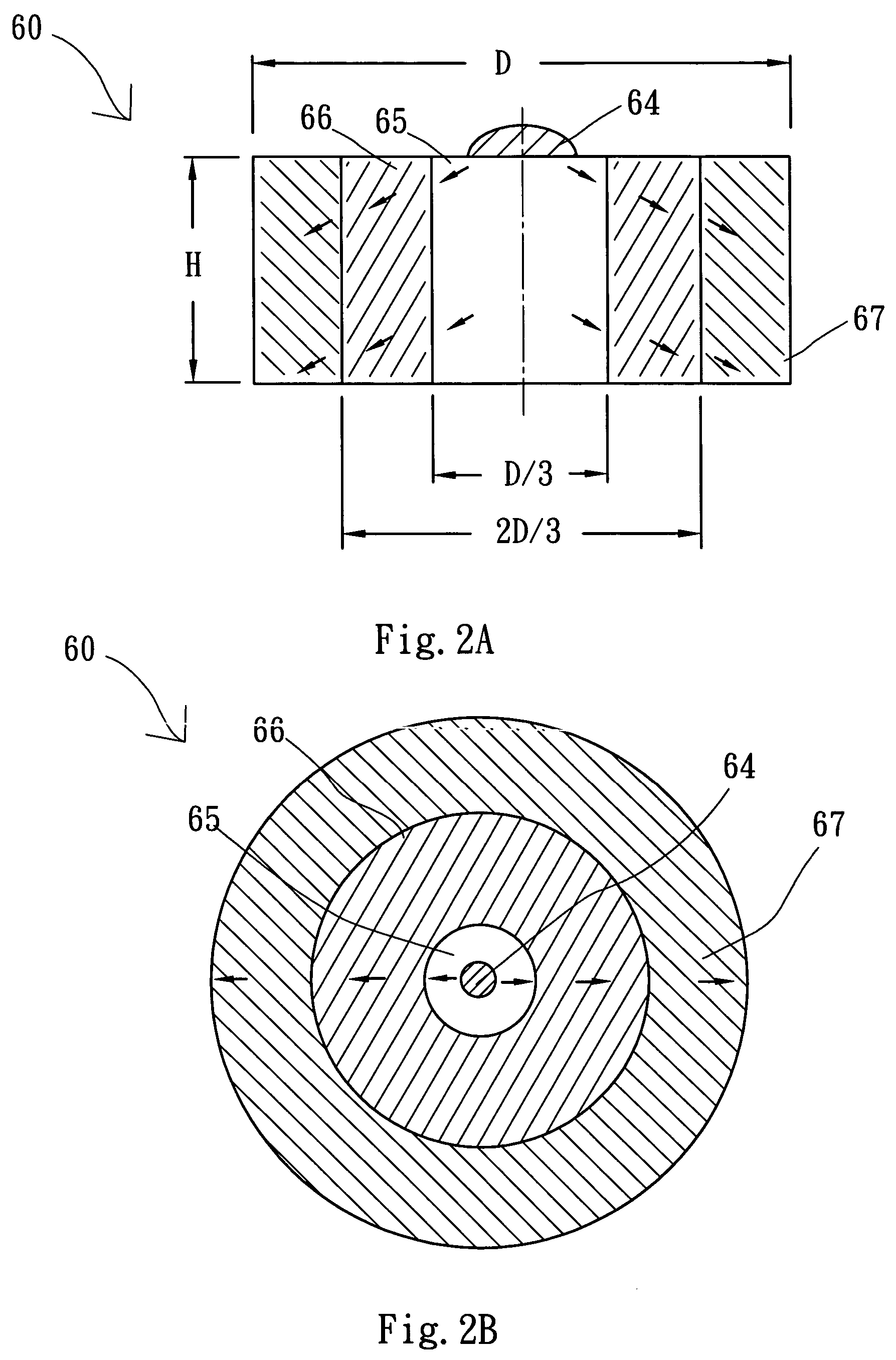

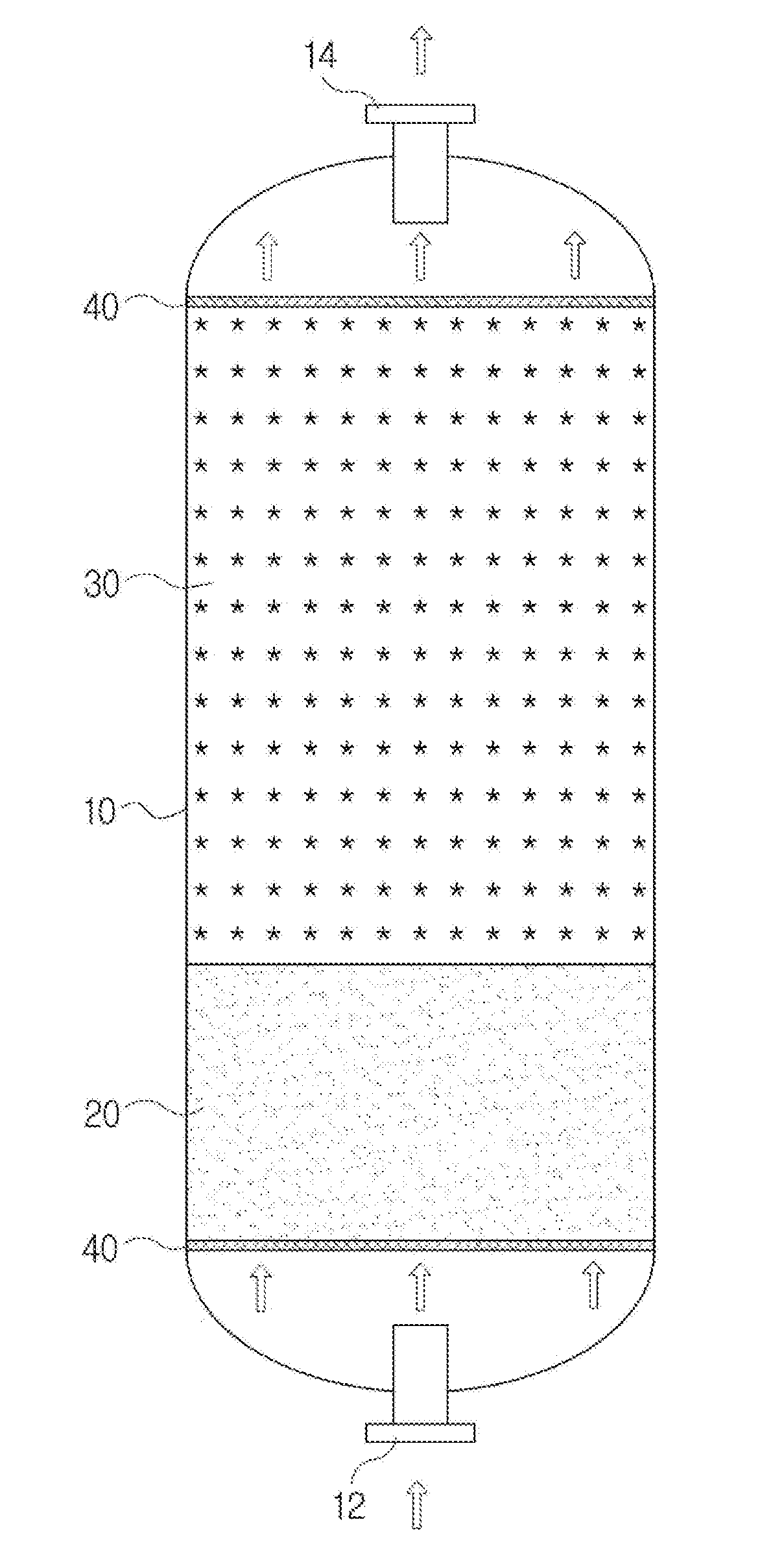

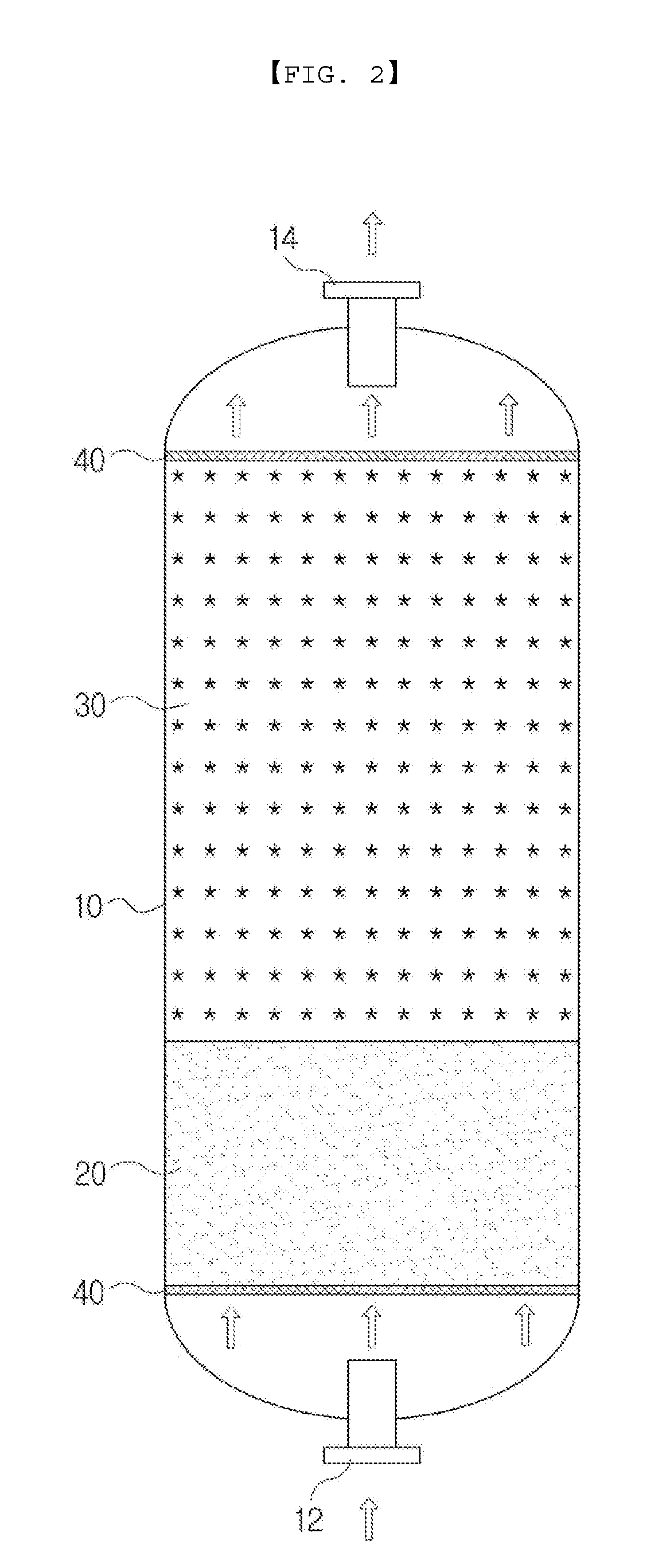

Adsorption tower for oxygen generating system containing two kinds of adsorbing agents filled therein

The present disclosure provides an adsorption tower for an oxygen generator system configured to adsorb nitrogen in air and supply oxygen, the tower comprising: a housing defining an inner space therein in which an adsorbing agent is filled; a housing inlet through which air enters into the housing; an housing outlet through which air is discharged from the housing, wherein the housing inlet is opposite to the housing outlet; a sodium based adsorbing agent layer disposed in the inner space and adjacent to the housing inlet; and a lithium-based adsorbing agent layer disposed in the inner space and adjacent the housing outlet.

Owner:WON HI TECH

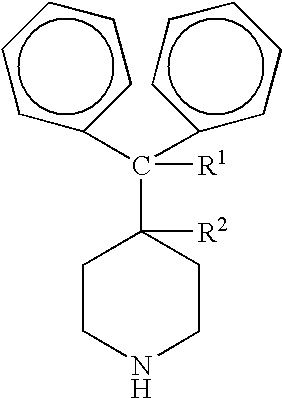

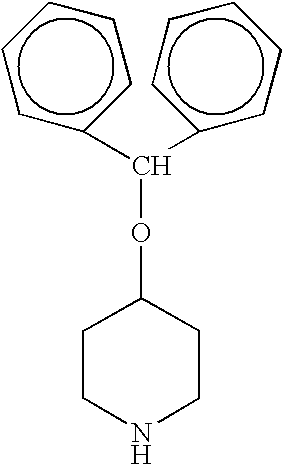

Process for the production of piperidine derivatives with microorganisms

The present invention relates to a process for the production of piperidine derivatives with microorganisms. This is carried out by incubating starting compounds in the presence of a microorganism under conditions effective to produce piperidine derivative products. Suitable microorganisms can be from any one of the genus of Stemphylium, Gliocladium, Bacillus, Botrytis, Cyathus, Rhizopus, Pycniodosphora, Pseudomonas, Helicostylum, Mucor, Gelasinospora, Rhodotorula, Candida, Mycobacterium, and Penicillium. In another aspect of the invention, starting compounds are incubated in the presence of Cunninghamella bainieria under conditions effective to produce piperidine derivative products.

Owner:ALBANY MOLECULAR RESEARCH INC

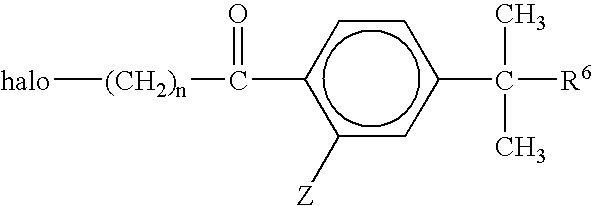

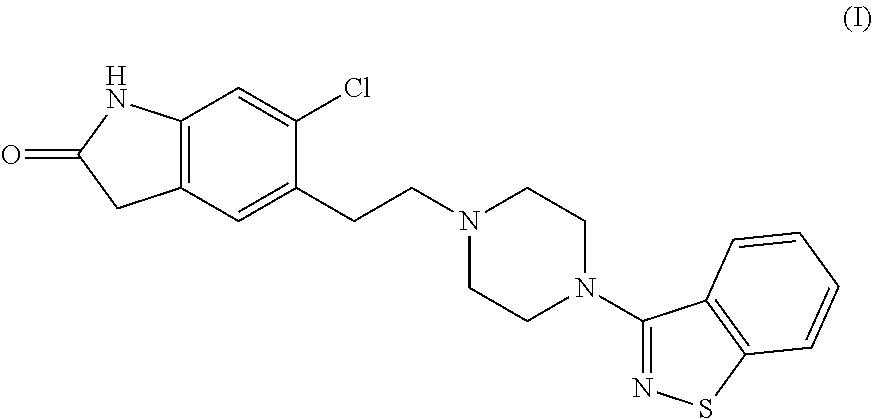

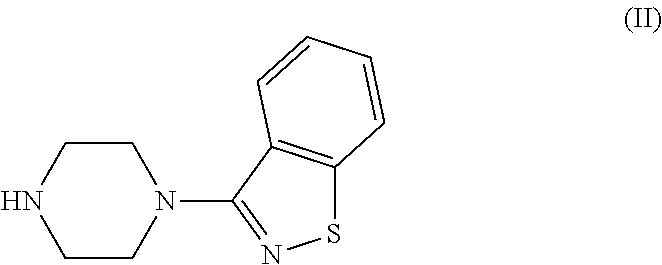

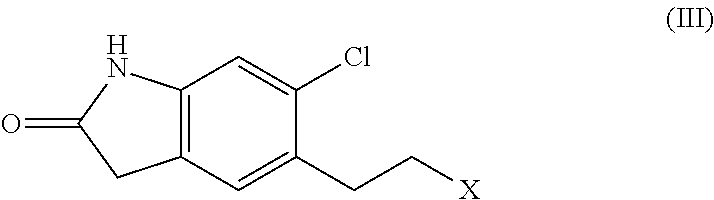

Process for the Preparation of Ziprasidone

The present invention relates to a process for preparing Ziprasidone of formula I,or a pharmaceutically acceptable salt or a solvate or a hydrate thereof;comprising the steps of reacting 1-(1,2-benzisothiazol-3-yl) piperazine of formula II or its salt:with 5-(2-haloethyl)-6-chloro-oxindole of formula III:wherein X is leaving groups like fluoro, chloro, bromo, iodo or sulphonyl;in the presence of a dispersing agent and a base in a solvent to form ziprasidone of formula I; and optionally converting the ziprasidone formed into a pharmaceutically acceptable acid addition salts of ziprasidone; or a solvate or a hydrate thereof.

Owner:ALKEM LAB LTD

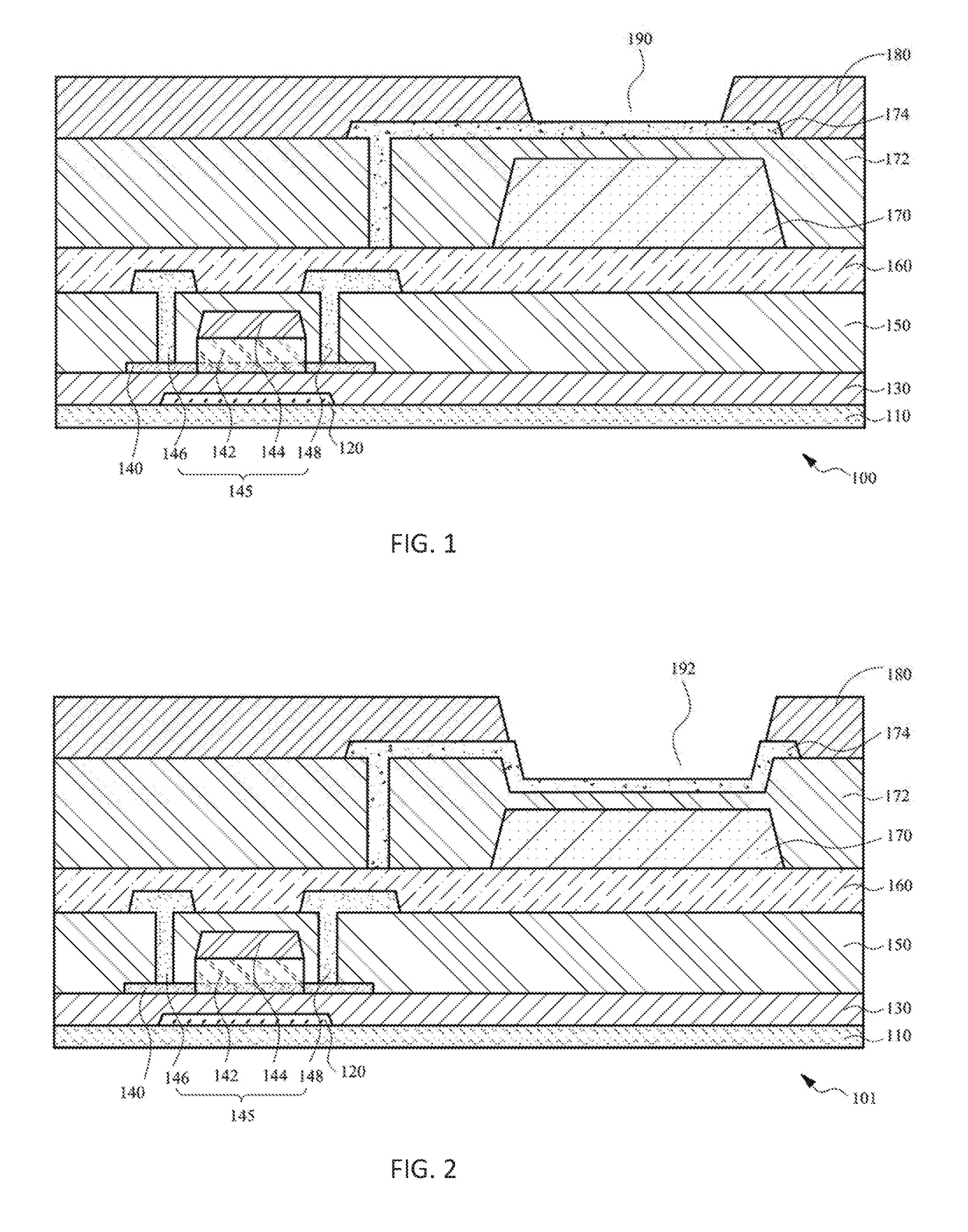

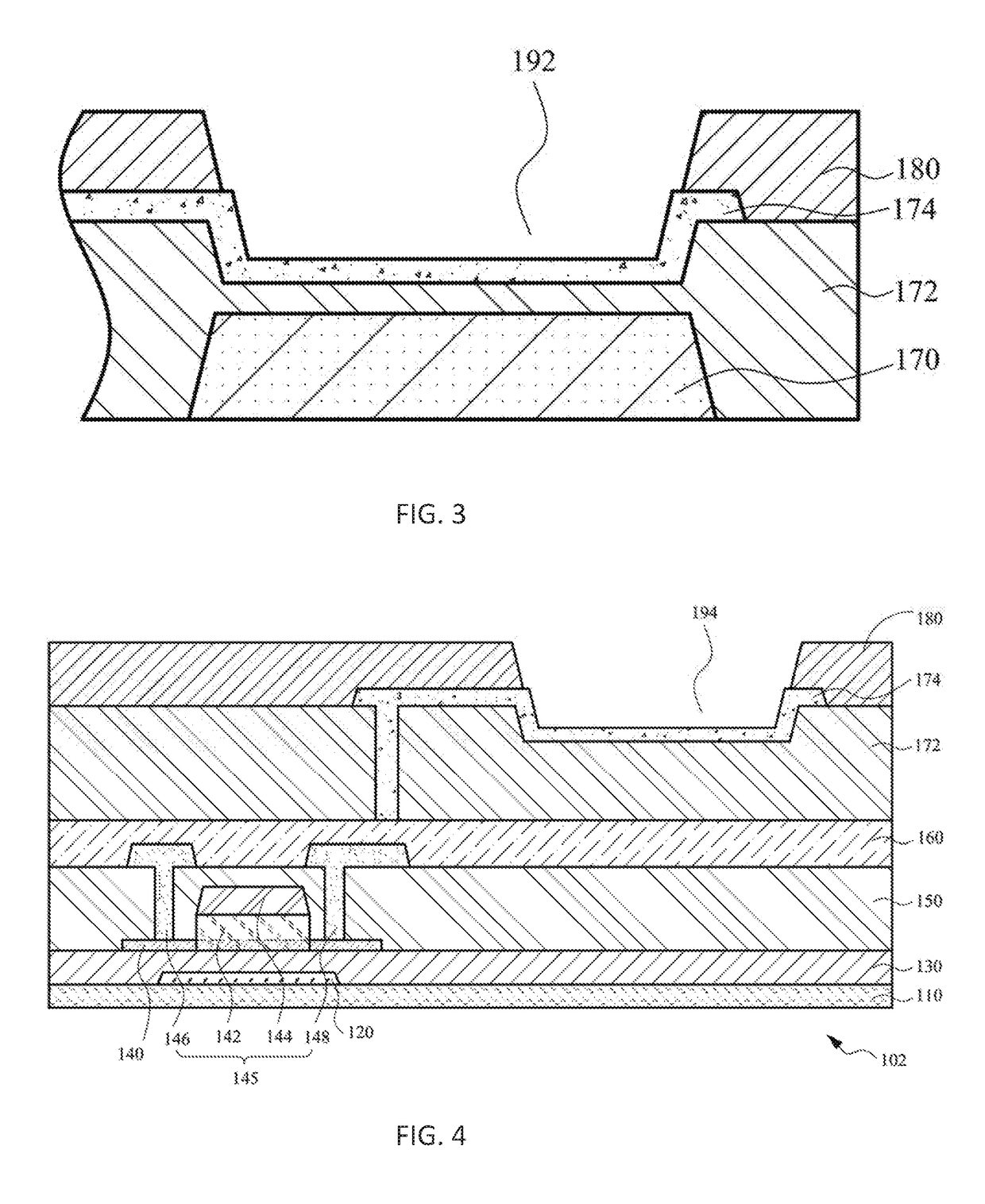

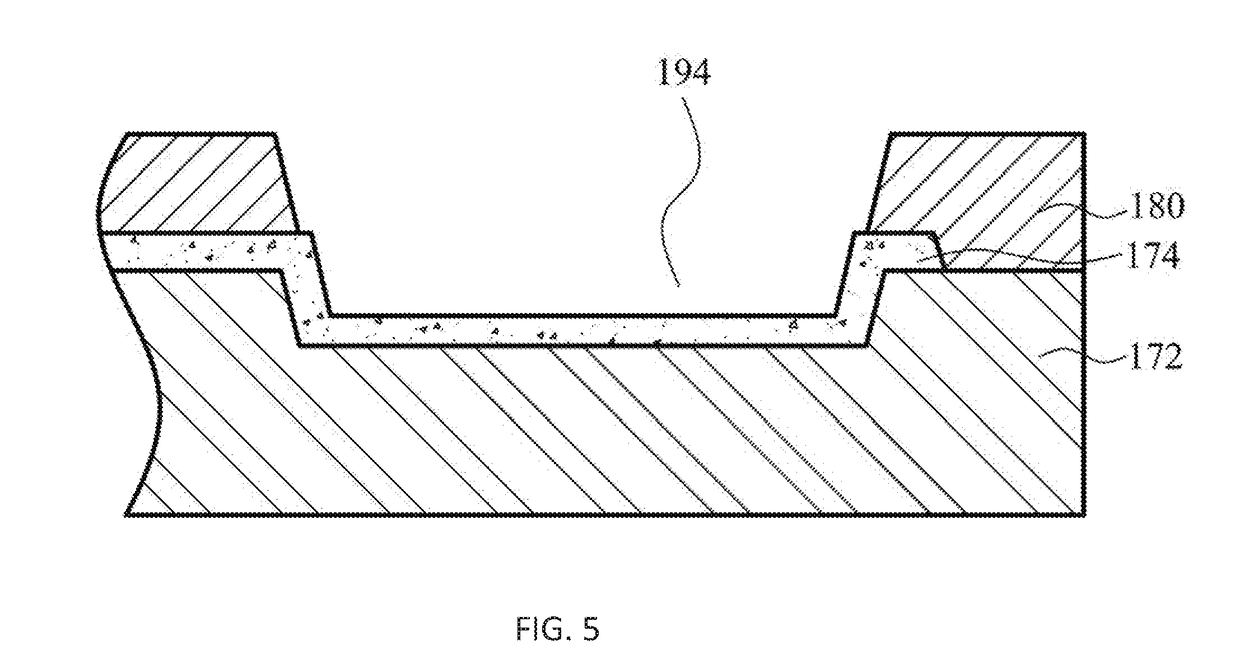

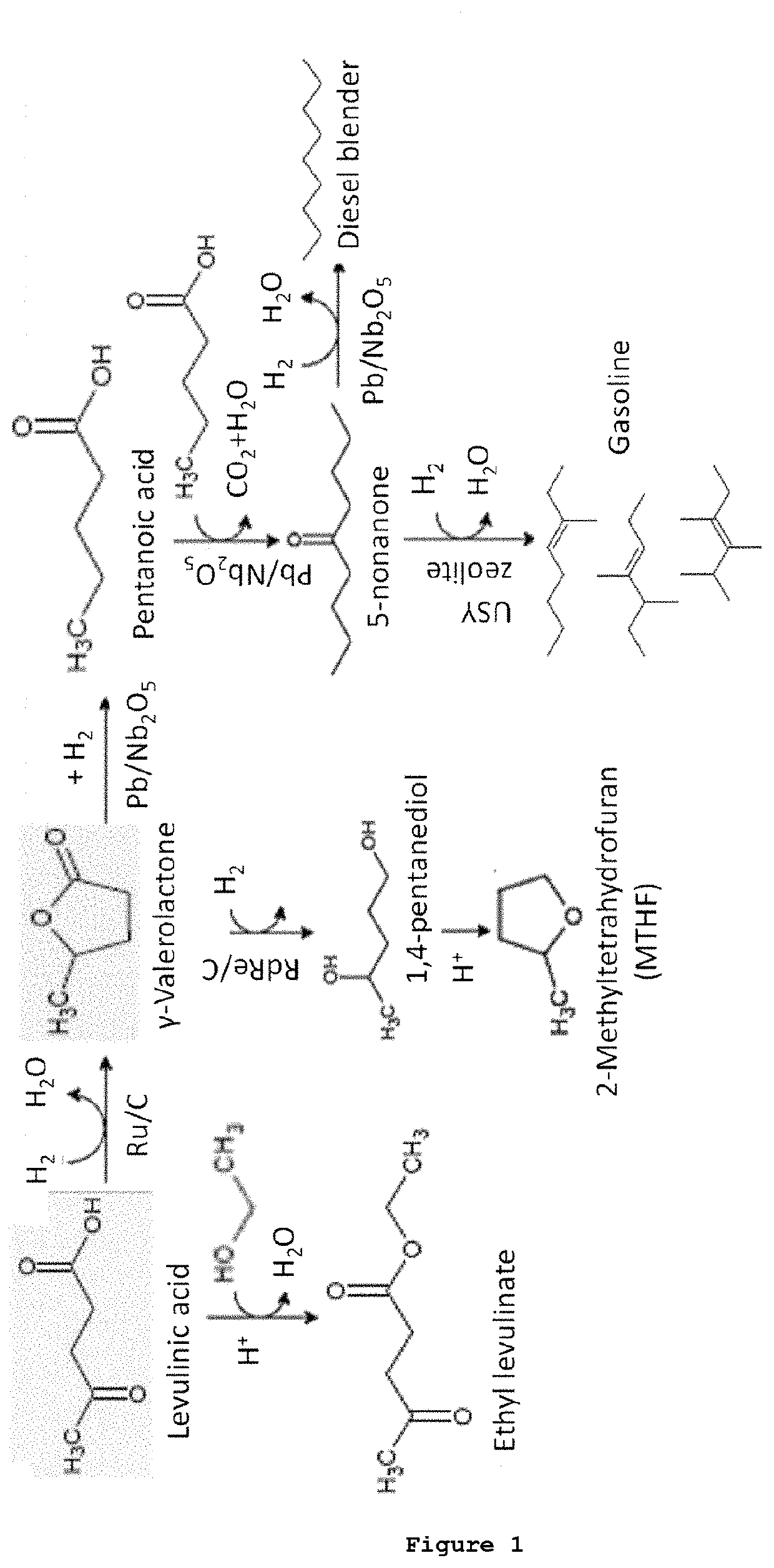

Display panel and method for manufacturing the same

InactiveUS20190067397A1Convenient lightingProcessingSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsTransistor

A display panel comprises a substrate, a plurality of thin film transistors arranged on the substrate, a passivation layer disposed on the substrate and covering the plurality of thin film transistors, a pixel definition layer disposed on the passivation layer and configured to enable a plurality of light emitting elements to be disposed therein, a planarization layer disposed between the passivation layer and the pixel definition layer and having a groove structure, a color filter layer disposed between the passivation layer and the planarization layer and corresponding to the location of the groove structure, and a transparent electrode layer disposed on the planarization layer and covering the groove structure. Wherein the plurality of light emitting elements are disposed in the groove structure of the planarization layer and is aligned to the location of the color filter layer.

Owner:HKC CORP LTD +1

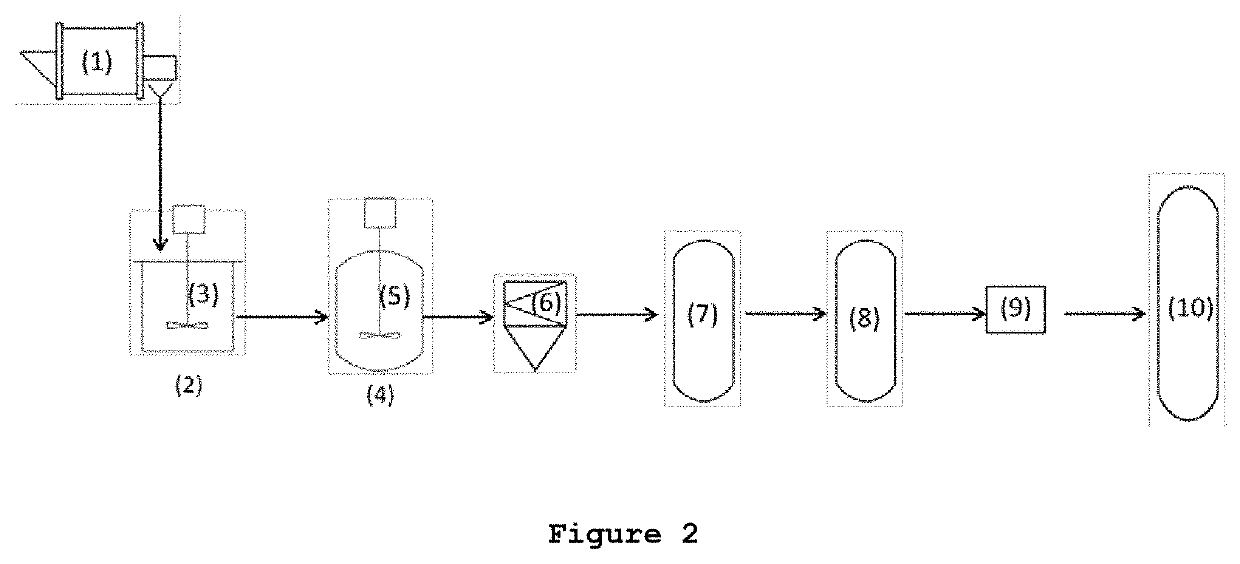

Levulinic acid purification

ActiveUS20210253508A1Increase productionReduce presenceOrganic compound preparationReverse osmosisLevulinic acidPropanoic acid

The present invention refers to a process for the purification of levulinic acid, an aqueous solution comprising levulinic acid and a process for the production of levulinic acid.

Owner:TECH REUNIDAS SA

Preparation method of pimaric acid type resin acid

InactiveUS8680232B2Increase temperatureYield andOrganic compound preparationNatural resin chemical modificationBottleSolvent

A method for preparing pimaric acid type resin acids includes the following steps: step (1) adding refined resin acid, turpentine, or rosin along with maleic anhydride at a mass ratio of 1:0.3-1.5 into a reaction bottle, dissolving the ingredients into a C1-C10 lower fatty acid solvent, the mass ratio of the C1-C10 low fatty acid to refined resin acid is 0.05-30:1, then carrying out additional reaction by heating directly or with assistance of a microwave, subsequently cooling, crystallizing, filtering, and washing; and step (2) combining the filtrates collected in step (1), stripping the solvent by vacuum distillation to obtain pimaric acid type resin acid coarse product, dissolving the resulting coarse product in NaOH aqueous solution to prepare aqueous solution of pimaric acid type resin acid salt, adjusting the pH level to 6-14 with a mineral acid or an organic acid while stirring, and either directly purifying or acidifying followed by purifying, the resulting precipitation to obtain the final product. The method has the characteristics of high yield, high product content, low cost, and low environmental pollution.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com