Pulping process for quality protection including methods for hemicellulose extraction and treatment of hemicellulose-extracted lignocellulosic materials

a quality protection and lignocellulosic material technology, applied in the field of modified pulping processes, can solve the problems of reducing the amount of wood that can go to pulping, and achieve the effect of more economical pulping process and yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

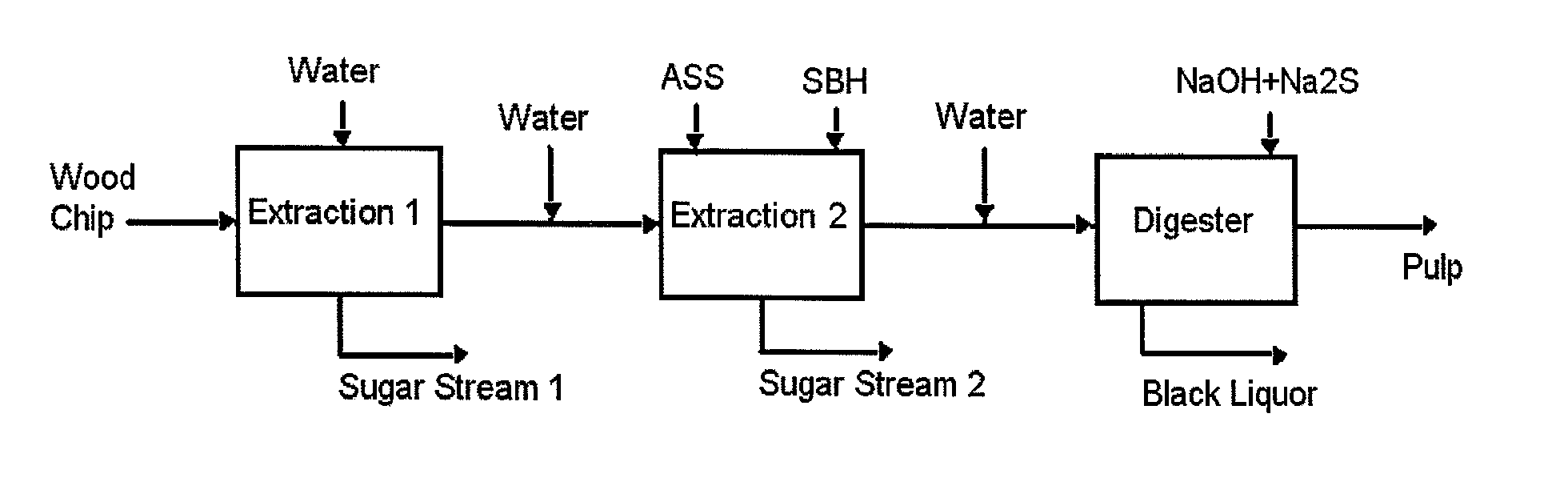

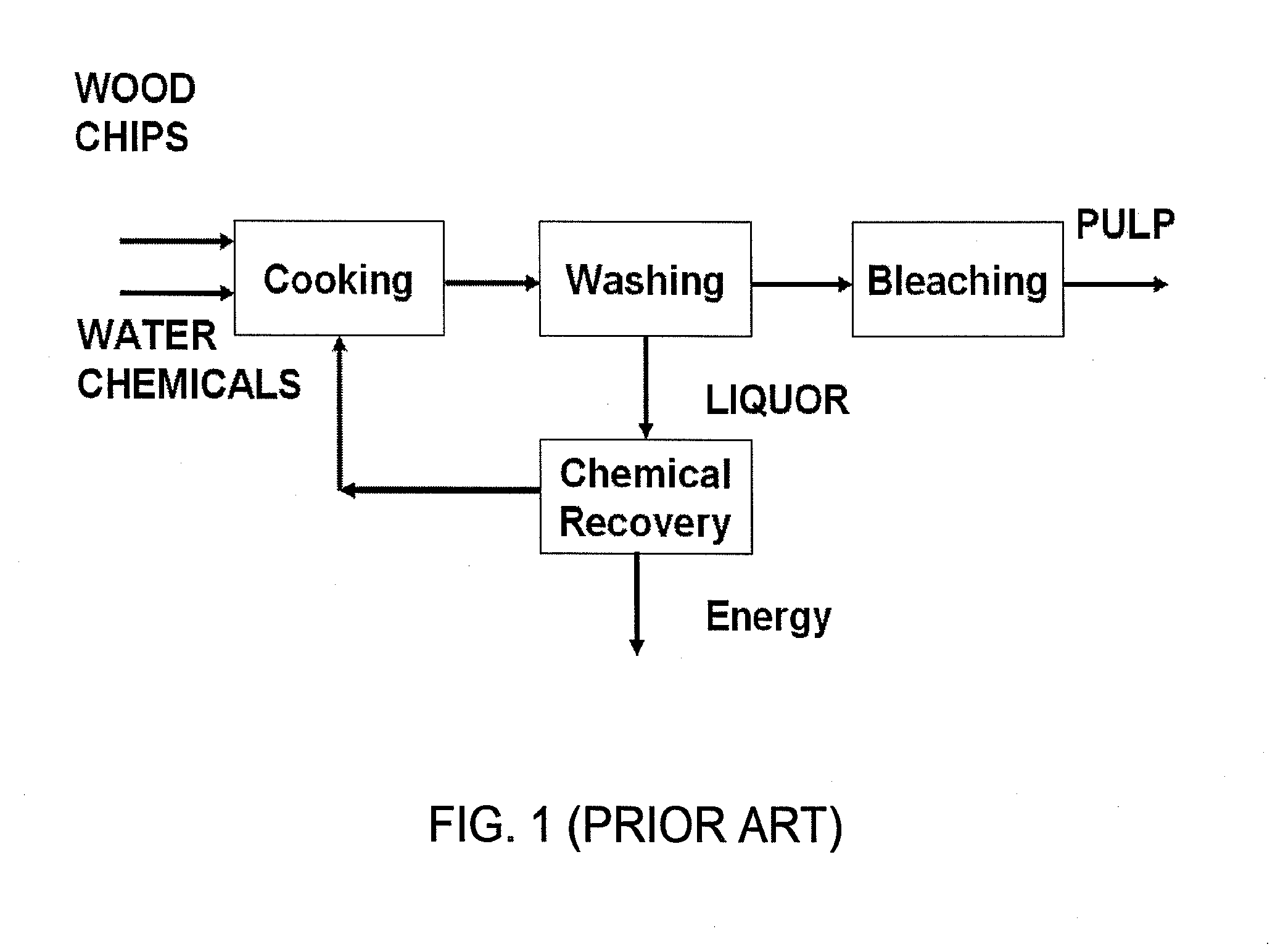

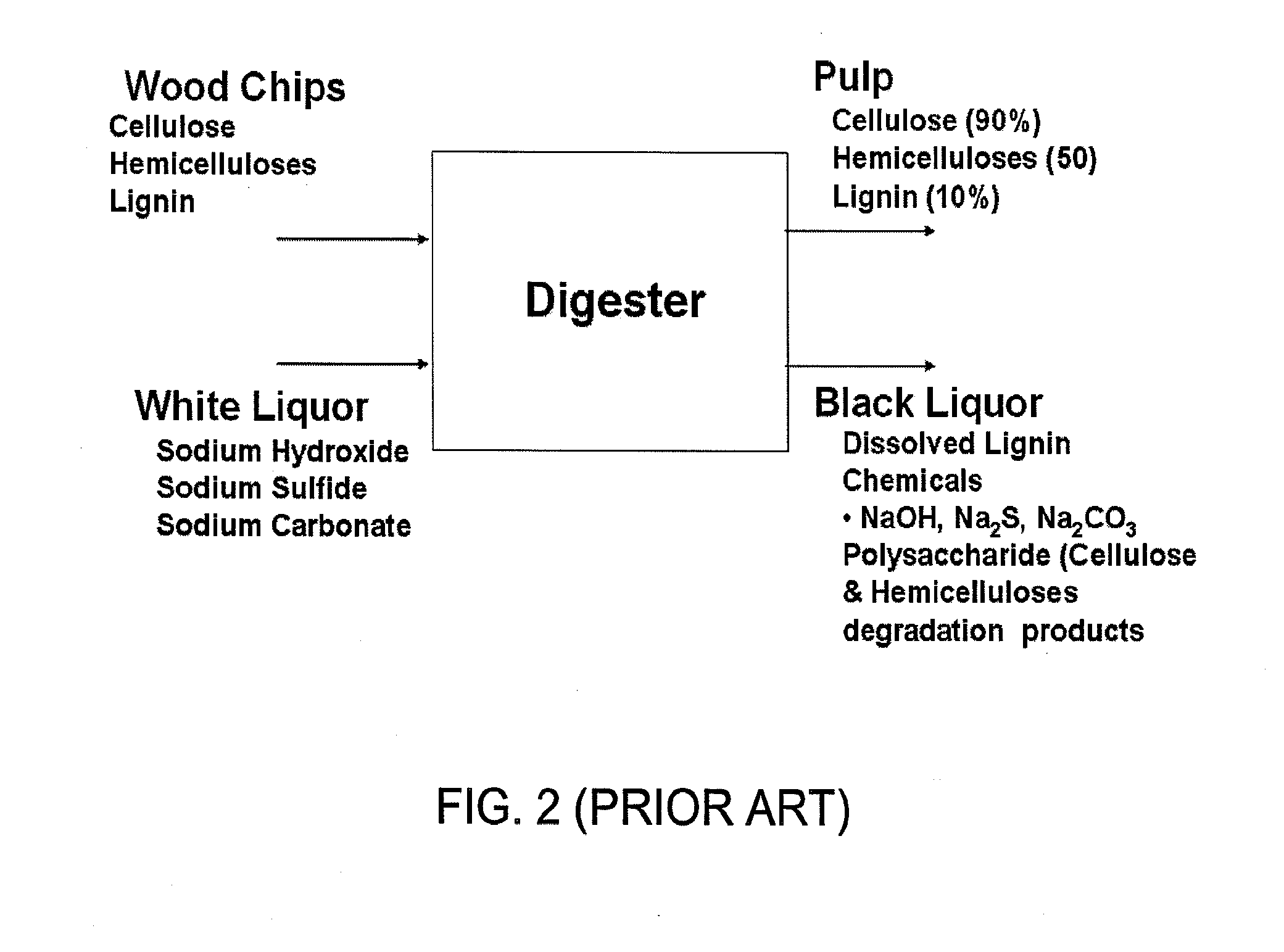

[0025]With reference to the figures, embodiments of the present invention are shown. The figures and the following description are for a limited number of embodiments for ease of understanding. However, the invention is not limited to these illustrative embodiments. Other processes and variations also are contemplated. For example, FIGS. 3-10 show block diagrams of representative Processes 1-8, respectively. Table 1 describes the conditions for various illustrative processes. Graphs 1-28 show results of the various illustrative processes and comparisons to controls such as prior art pulp and paper made from prior art pulp.

[0026]The present invention comprises continuous processes for protecting hemicellulose pre-extracted lignocellulosic materials, such as wood chips, against degradation in alkaline pulping processes. After pre-extraction, the lignocellulosic materials are treated with reducing and / or oxidizing agents before or during the alkaline pulping process to maintain the yie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com