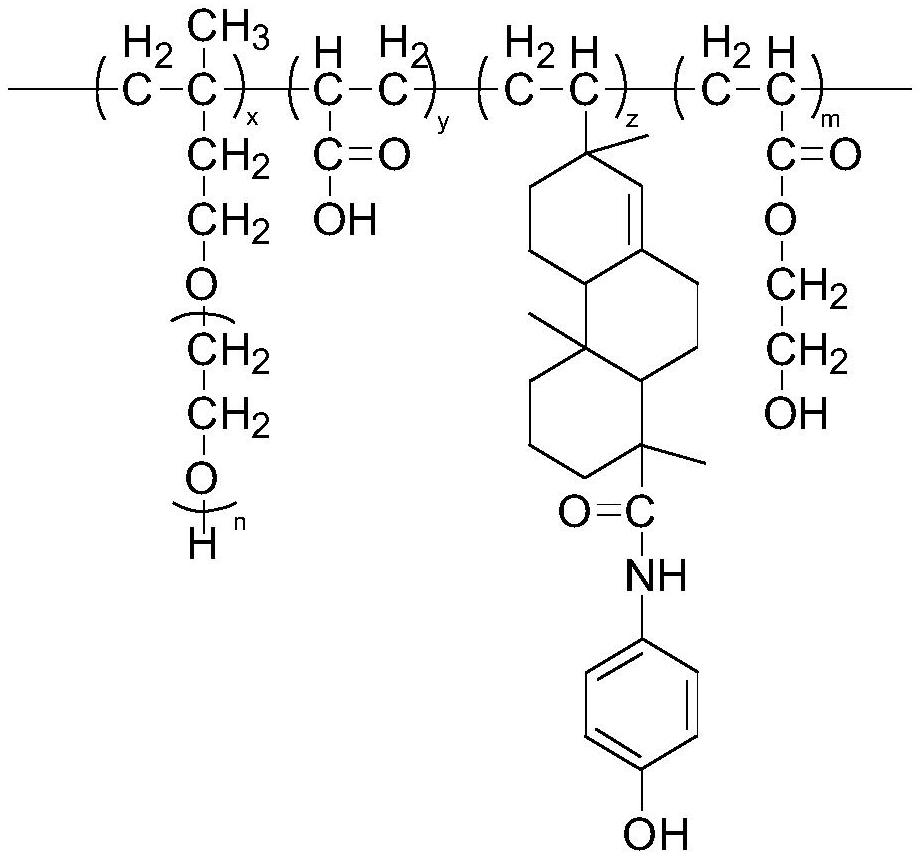

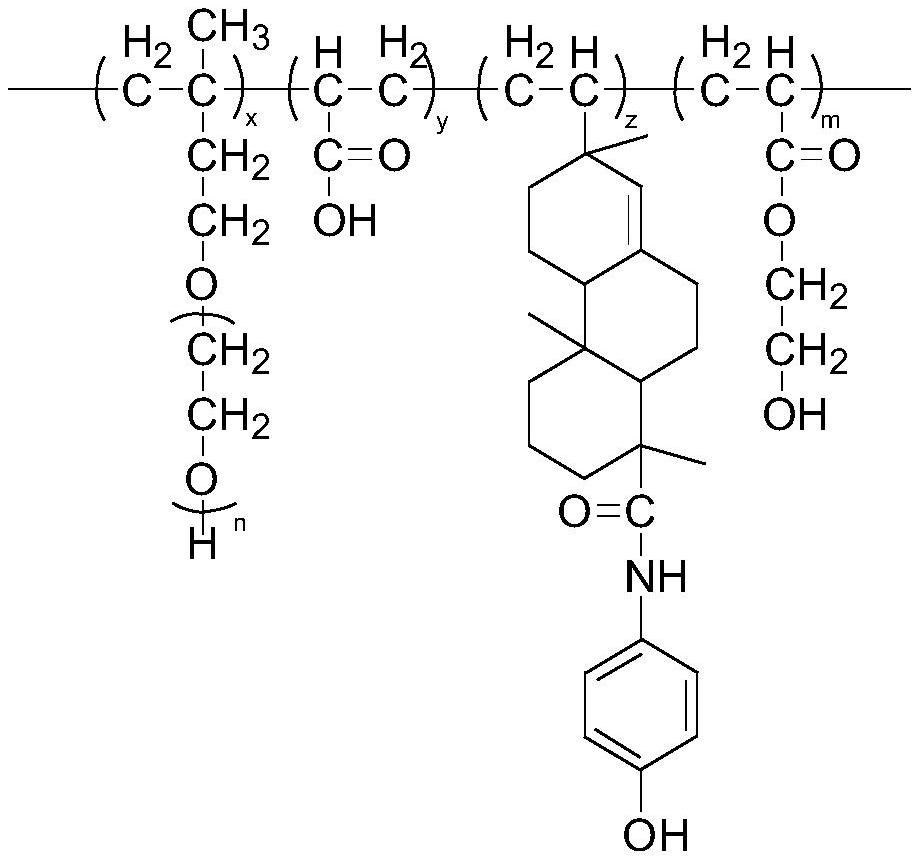

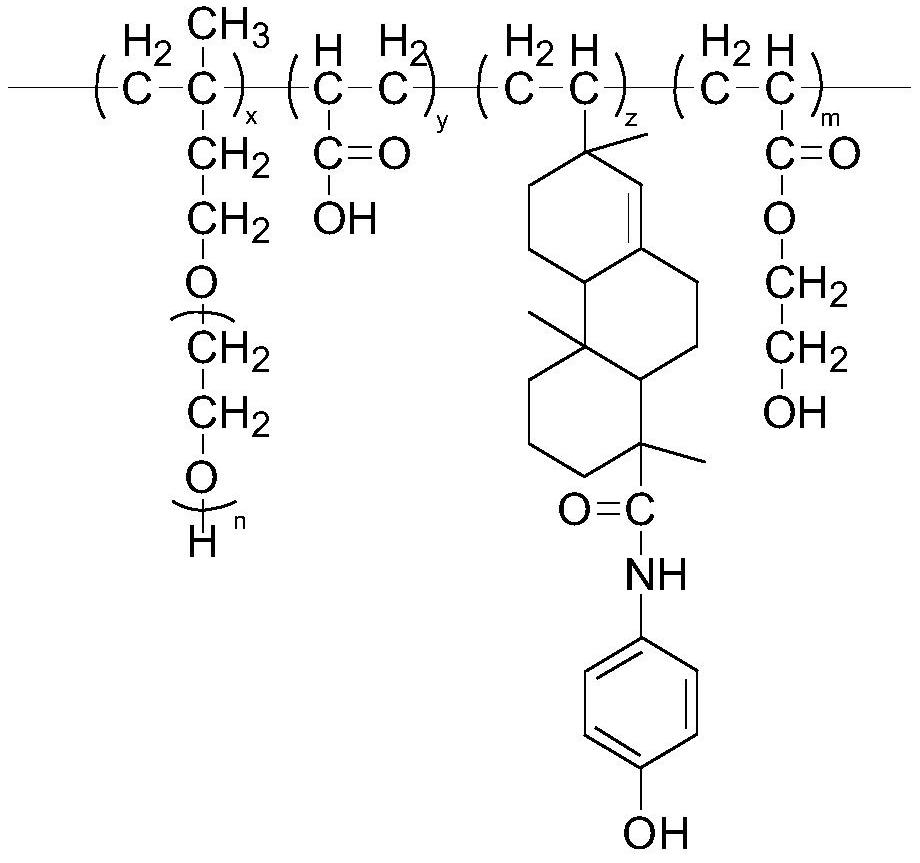

Polycarboxylate superplasticizer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete admixture, can solve the problem of reducing the use efficiency of air-entraining agent and water reducing agent, reducing the strength and crack resistance of concrete, and incompatibility between air-entraining agent and water reducing agent To achieve the flexible and controllable air-entrained content, improve the anti-permeability and anti-cracking performance, and avoid the effect of concrete delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a preparation method of polycarboxylate water reducer, comprising the steps of:

[0060] (1) Add pimaric acid type resin acid, p-aminophenol, ethanol and catalyst into the first reaction vessel, raise the temperature to 78°C, and react for 3-5 hours. After the reaction, distill ethanol to obtain unsaturated air-entraining functional mono body;

[0061] Among them, the mass ratio of pimaric acid-type resin acid, p-aminophenol, ethanol and catalyst added is 100: (30-50): 200: (0.1-0.5);

[0062] (2) In parts by weight, add 200 parts of isopentenyl polyoxyethylene ether, 20-80 parts of unsaturated air-entraining functional monomer, 2-10 parts of unsaturated monomer and 200-300 parts of water into the second Mix in the reaction vessel, stir and dissolve, add 0.5-3.0 parts of initiator to the second reaction vessel, heat to 60-85°C; add the first mixed solution and the second mixed solution to the second reaction vessel at the same time, ...

Embodiment 1

[0081] The preparation method of polycarboxylate water reducer comprises the steps:

[0082] (1) In parts by weight, add 100 parts of pimaric acid, 40 parts of p-aminophenol, 200 parts of ethanol and 0.3 part of p-toluenesulfonic acid into the first reaction container, connect the condensing device, heat up to 78 ° C, stir and reflux the reaction After 4 hours, after the reaction was finished, distill ethanol to obtain an unsaturated air-entraining functional monomer;

[0083] (2) In parts by weight, add 200 parts of isopentenyl polyoxyethylene ether (molecular weight: 1200), 30 parts of unsaturated air-entraining functional monomer, 5 parts of acrylic acid and 250 parts of deionized water into the second reaction vessel Mix in medium, heat to 70°C, stir and dissolve, then add 2.5 parts of hydrogen peroxide into the second reaction container; at the same time, drop the first mixed solution and the second mixed solution into the second reaction container, the first mixed soluti...

Embodiment 2

[0086] The preparation method of polycarboxylate water reducer comprises the steps:

[0087] (1) In parts by weight, add 100 parts of isopimaric acid, 45 parts of p-aminophenol, 200 parts of ethanol and 0.3 part of concentrated sulfuric acid into the first reaction vessel, connect the condensing device, heat up to 78 ° C, stir and reflux reaction 4 hour, after the reaction finishes, distill ethanol to obtain unsaturated air-entraining type functional monomer;

[0088] (2) In parts by weight, add 200 parts of isopentenyl polyoxyethylene ether (molecular weight: 2400), 50 parts of unsaturated air-entraining functional monomer, 5 parts of acrylic acid and 250 parts of deionized water into the second reaction vessel Mix in medium, heat to 70°C, stir and dissolve, add 3.0 parts of hydrogen peroxide to the second reaction container; at the same time, drop the first mixed solution and the second mixed solution into the second reaction container, the first mixed solution is at 2.5 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com