Slush-molded PVC material for automotive trim skin and preparation method of slush-molded PVC material

A technology for PVC materials and automotive interiors, applied in the chemical industry, can solve the problems of easy injury to the human body, and achieve the effect of dry material, good fluidity, internal lubricity and external lubricity, and overall compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 and embodiment 2 use suspension method PVC and the processing mixing of various oils and fats in formula.

Embodiment 2

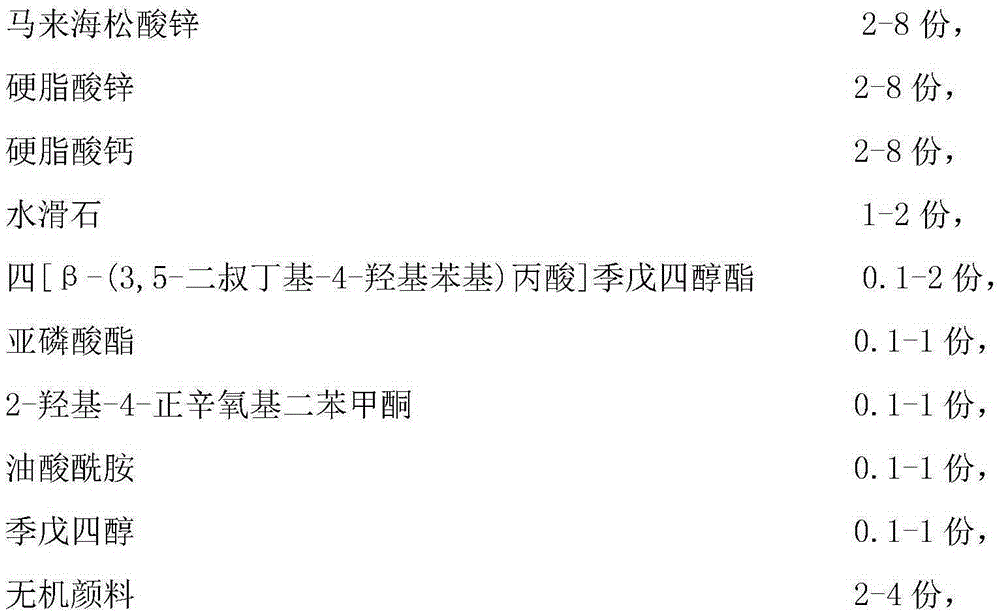

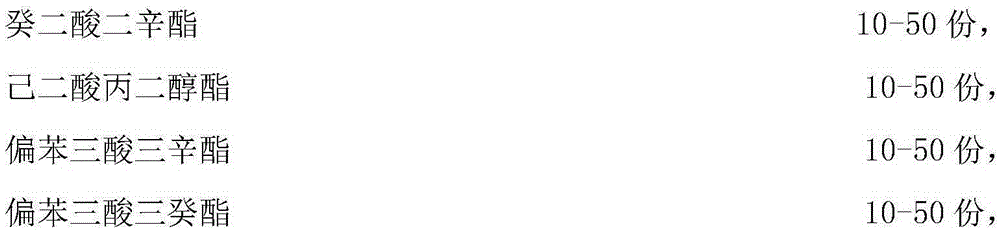

[0052] Add 100 parts of PVC resin by suspension method into the reaction kettle, stir and heat up to the predetermined temperature, add 1 part of hydrotalcite, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol 0.5 part, 0.5 part of phosphite, 0.5 part of 2-hydroxy-4-n-octyloxybenzophenone, 0.5 part of oleic acid amide, 0.1 part of pentaerythritol, 0.2 part of inorganic pigment carbon black, continue to add zinc maleopimarate 4 1 part, 1 part of zinc stearate, 1 part of calcium stearate, after 10 minutes to 70 degrees temperature, spray and add 100 parts of premixed oil (propylene glycol adipate, trioctyl trimellitate, trimellitic acid 32 parts of three capric acid esters, 6 parts of diacetyl epoxy vegetable glyceryl oleate), increase the rotating speed and adjust the baffle plate, when the temperature rises to 125 degrees, the grease is completely absorbed, and the material remains dry. Then transfer to the cooling kettle at a high speed of 300 rpm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com