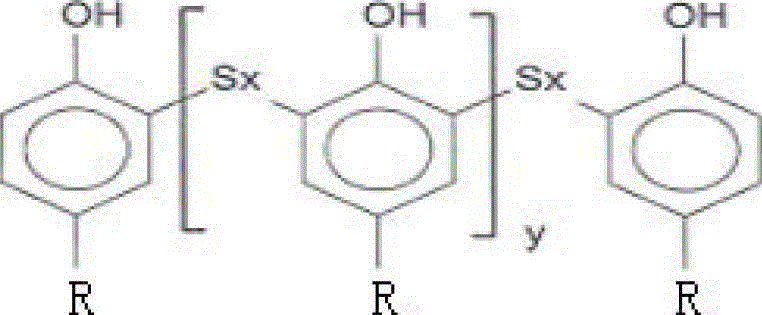

Modified rosin tackifying resin as well as preparation method and application thereof

A tackifying resin and modified rosin technology, applied in rosin adhesives, applications, rosin coatings, etc., can solve the problems of application limitations, high equipment requirements, high softening point of resin, etc., and achieve better wettability and adhesion , wide range of applications, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

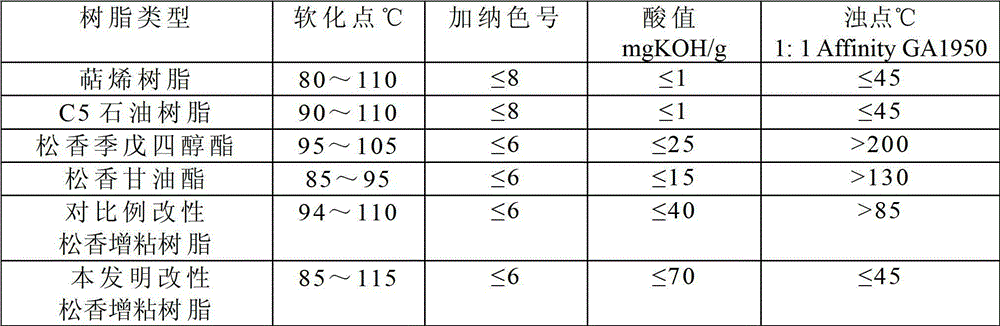

Embodiment 1

[0035]Add 365 grams of rosin, 0.37 grams of 300, 275 grams of dicyclopentadiene fraction with a dicyclopentadiene content of 83wt%, and 33.73 grams of turpentine in a high-pressure reactor with a volume of 1 L. The temperature is raised to 265 ° C within 2 hours, and the pressure is 0.52Mpa , reacted for 2 hours, decompressed, flashed to remove low boiling point substances, then cooled to 220 ° C, added 0.36 grams of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.36 gram of tris(2,4-di-tert-butylphenyl)phosphite, and stirred for 10 minutes to release to obtain modified rosin tackifying resin. The softening point of the resin is 93°C, acid value: 34.2 (mgKOH / g), color: Garner color 3.5, cloud point (1:1Affinity GA1950) <25°C.

Embodiment 2

[0037] Add 365 grams of rosin and 0.9 grams of ROSINOX to a 1L autoclave TM , 275 grams of dicyclopentadiene fractions with a dicyclopentadiene content of 83wt%, 45 grams of turpentine, heated to 265 ° C within 2 hours, and the pressure was 0.52Mpa, reacted for 5 hours, decompressed, flashed to remove low boiling point substances, and then cooled to 220°C, add 0.73 g tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 1.1 g tris(2,4-di-tert-butylphenyl) phosphite , Stir for 10 minutes to release, to obtain modified rosin tackifying resin. The softening point of the resin is 94°C, acid value: 35.3 (mgKOH / g), color: Garner color 4, cloud point (1:1Affinity GA1950) <25°C.

Embodiment 3

[0039] Add 300 grams of rosin and 0.9 grams of ROSINOX to a 1L autoclave TM , 335 grams of dicyclopentadiene fractions with a dicyclopentadiene content of 83wt%, 45 grams of turpentine, heated to 265 ° C within 2 hours, and the pressure was 0.55Mpa, reacted for 3.5 hours, decompressed, flashed to remove low boiling point substances, and then cooled to 220°C, add 0.6 g tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.3 g tris(2,4-di-tert-butylphenyl) phosphite , Stir for 10 minutes to release, to obtain modified rosin tackifying resin. The resin has a softening point of 105°C, an acid value of 21.3 (mgKOH / g), a color of Garner color 4+, and a cloud point (1:1 AffinityGA1950) of 32°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com