Rosin viscosified resin as well as preparation method and application thereof

A technology of tackifying resin and rosin, which is applied in the preparation of rosin tackifying resin and the field of rosin tackifying resin, and can solve problems such as poor compatibility and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

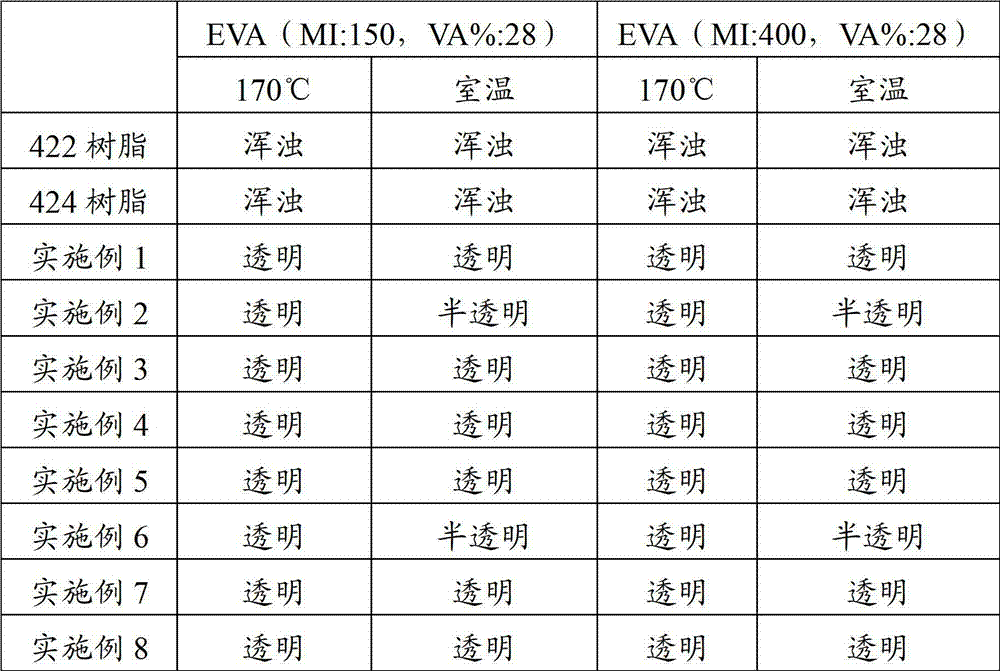

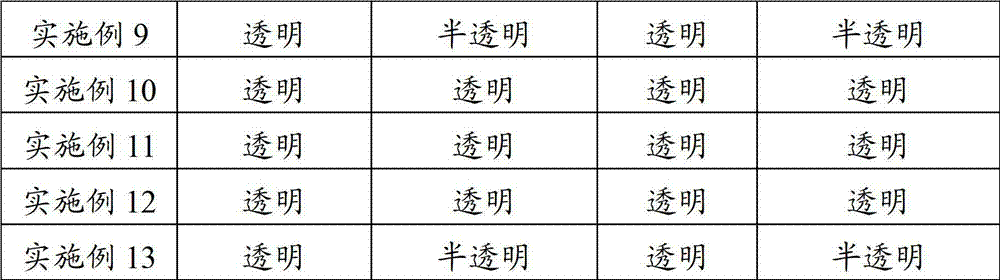

Examples

Embodiment 1

[0023] A kind of rosin tackifying resin, adopts following method to prepare:

[0024] (1) Weigh 700 grams of Indonesian rosin, crush it and put it into a distillation bottle, and add 0.7 grams of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester at the same time, Vacuumize, heat to a temperature of 240°C, observe the proportion of rosin steamed by the receiving bottle with a scale marked on it, and distill until the content of rosinic acid in the rosin is 10% by weight, stop the distillation and release the vacuum;

[0025] (2) Weigh 300 grams of rosin left in the distillation bottle after distillation in step (1), and then weigh 33 grams of pentaerythritol, 4,4'-thiobis(6-tert-butyl-3-methylphenol) Add 0.45 g into a four-necked flask, react at 280° C. for 9 hours under nitrogen protection, and discharge to obtain rosin resin.

[0026] Measured by the ring and ball method, the softening point of the rosin tackifying resin obtained in this embodi...

Embodiment 2

[0028] A kind of rosin tackifying resin, adopts following method to prepare:

[0029] (1) Weigh 700 grams of Indonesian rosin, crush it and put it into a distillation bottle, and add 0.7 grams of n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate at the same time , evacuated, heated to a temperature of 250°C, observed the proportion of steamed rosin in the receiving bottle with a marked scale, distilled until the content of rosinic acid in the rosin was 10% by weight, stopped the distillation and released the vacuum;

[0030] (2) Weigh 300 grams of rosin left in the distillation bottle after the distillation in step (1), then weigh 37.5 grams of pentaerythritol, and add 0.15 grams of polyalkylphenol disulfide compound into a four-necked flask, at 240°C under nitrogen protection After 24 hours of reaction, the rosin resin was obtained.

[0031] Measured by the ring and ball method, the softening point of the rosin tackifying resin obtained in this embodiment is 120° C...

Embodiment 3

[0033] A kind of rosin tackifying resin, adopts following method to prepare:

[0034] (1) Weigh 700 grams of Indonesian rosin, crush it and put it into a distillation bottle, and add 0.35 grams of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester at the same time, Vacuumize, heat to a temperature of 260°C, observe the proportion of rosin evaporated according to the receiving bottle with a marked scale, distill until the content of rosinic acid in the rosin is 16% by weight, stop the distillation and release the vacuum;

[0035] (2) Weigh 300 grams of rosin left in the distillation bottle after distillation in step (1), and then weigh 39 grams of pentaerythritol, 4,4'-thiobis(6-tert-butyl-3-methylphenol) Add 1.5 grams into a four-necked flask, react at 290° C. for 4 hours under nitrogen protection, and discharge the material to obtain rosin resin.

[0036] Measured by the ring and ball method, the softening point of the rosin tackifying resin obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com