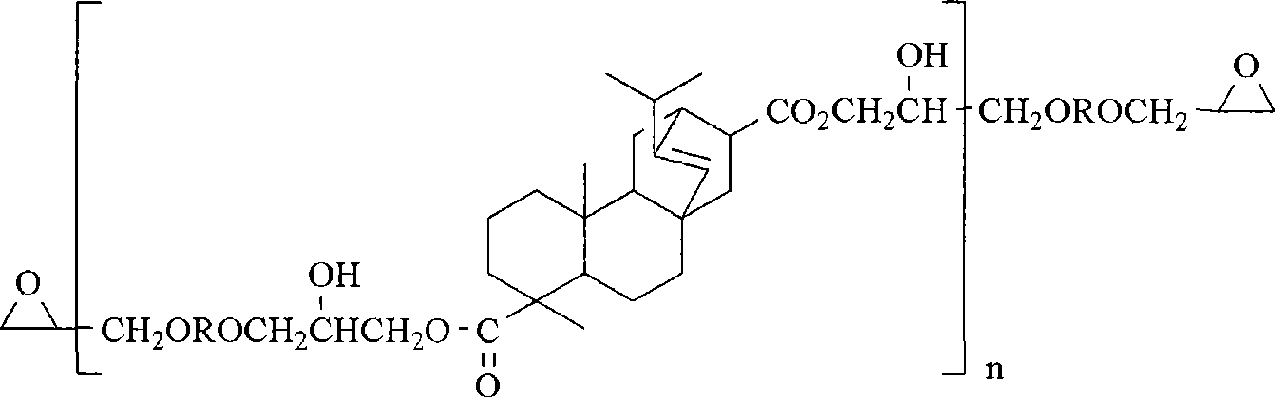

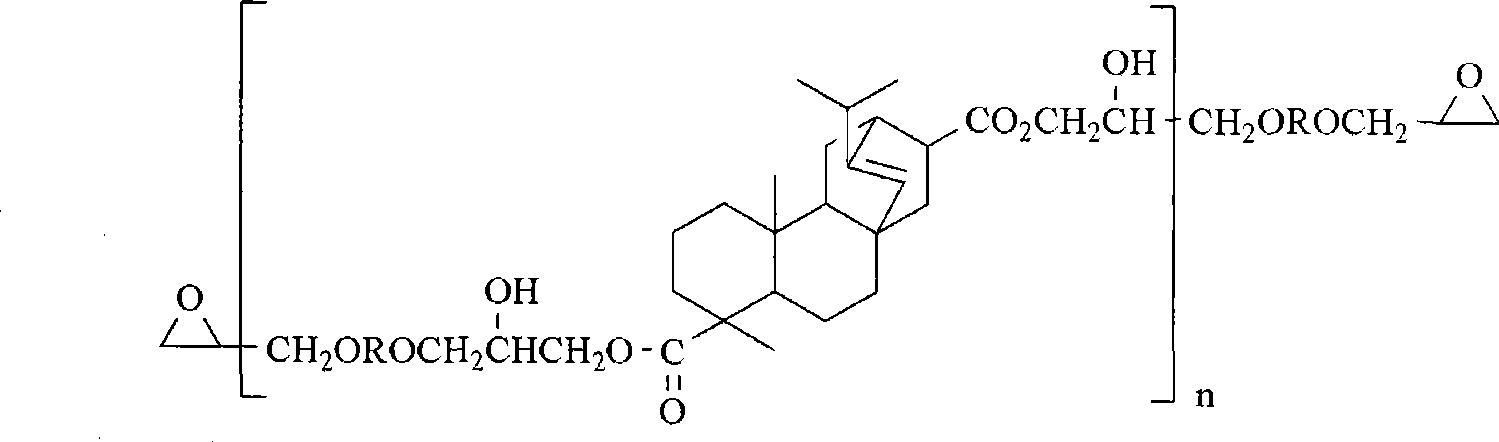

Acrylic acid rosin and epoxy resin prepolymer and preparation method thereof

A technology of acrylic rosin epoxy resin and acrylic rosin, which is applied in the direction of chemical modification of natural resins, can solve the problems of short aliphatic chains and brittle cured products, and achieve the effects of improving weather resistance, increasing productivity and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

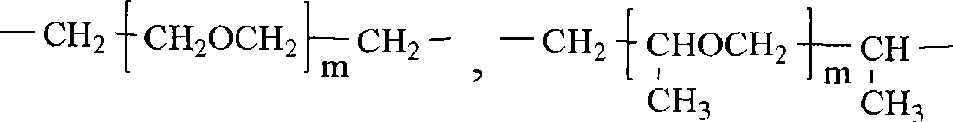

Embodiment 1

[0026] Crush 100g of acrylic rosin, put it into a 500mL four-necked flask with a mechanical stirrer, a reflux condenser, a dropping funnel and a nitrogen conduit, introduce nitrogen for protection, heat it to melt, add 145g of triethylene glycol Diglycidyl ether (the ratio of acrylic rosin and triethylene glycol diglycidyl ether is 1:2), stir to make the system uniform, and then add 0.06wt% (calculated on acrylic rosin) of tetramethylammonium chloride As a catalyst, the reaction was stirred at a temperature of 160 ° C for 7 hours, and the reaction was stopped when the acid value of the reaction system was lower than 1 mgKOH / g. After cooling, a yellow viscous resin was obtained. After infrared analysis, there was 1722 cm -1 , 1132cm -1 , 1250cm -1 , 912cm -1 and 854cm -1 Isotactic absorption, epoxy value 0.17mol / 100g, viscosity (36°C) 14.2Pa·s, acid value 0.3mgKOH / g, number average molecular weight 4800.

Embodiment 2

[0028] Crush 100g of acrylic rosin, put it into a 500mL four-necked flask with a mechanical stirrer, a reflux condenser, a dropping funnel and a nitrogen conduit, introduce nitrogen for protection, heat it to melt, add 164g of polypropylene glycol dihydrate Glyceryl ether (the ratio of acrylic rosin to polypropylene glycol diglycidyl ether is 1:2), stir to make the system uniform, then add 0.01wt% (calculated on acrylic rosin) potassium hydroxide as a catalyst, at a temperature of 170 ° C The reaction was stirred for 9 hours, and the reaction was stopped when the acid value of the reaction system was lower than 1 mgKOH / g. After cooling, a yellow viscous resin was obtained. After infrared analysis, there was 1722 cm -1 , 1132cm -1 , 1250cm -1 , 912cm -1 and 854cm -1 Isotactic absorption, epoxy value 0.16mol / 100g, viscosity (36°C) 13.5Pa·s, acid value 0.2mgKOH / g, number average molecular weight 4200.

Embodiment 3

[0030] Crush 100g of acrylic rosin, put it into a 500mL four-necked flask with a mechanical stirrer, a reflux condenser, a dropping funnel and a nitrogen conduit, introduce nitrogen for protection, heat it to melt, add 125g of butanediol two Glycidyl ether (the ratio of acrylic rosin and butanediol diglycidyl ether substances is 1:2), stir to make the system uniform, then add 0.03wt% (calculated on acrylic rosin) triethylamine as a catalyst, at 130 The reaction was stirred at a temperature of ℃ for 5 hours, and the reaction was stopped when the acid value of the reaction system was lower than 1 mgKOH / g. After cooling, a yellow viscous resin was obtained. After infrared analysis, there was 1722 cm -1 , 1132cm -1 , 1250cm -1 , 912cm -1 and 854cm -1 Isotactic absorption, epoxy value 0.19mol / 100g, viscosity (36°C) 15.7Pa·s, acid value 0.6mgKOH / g, number average molecular weight 5400.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com