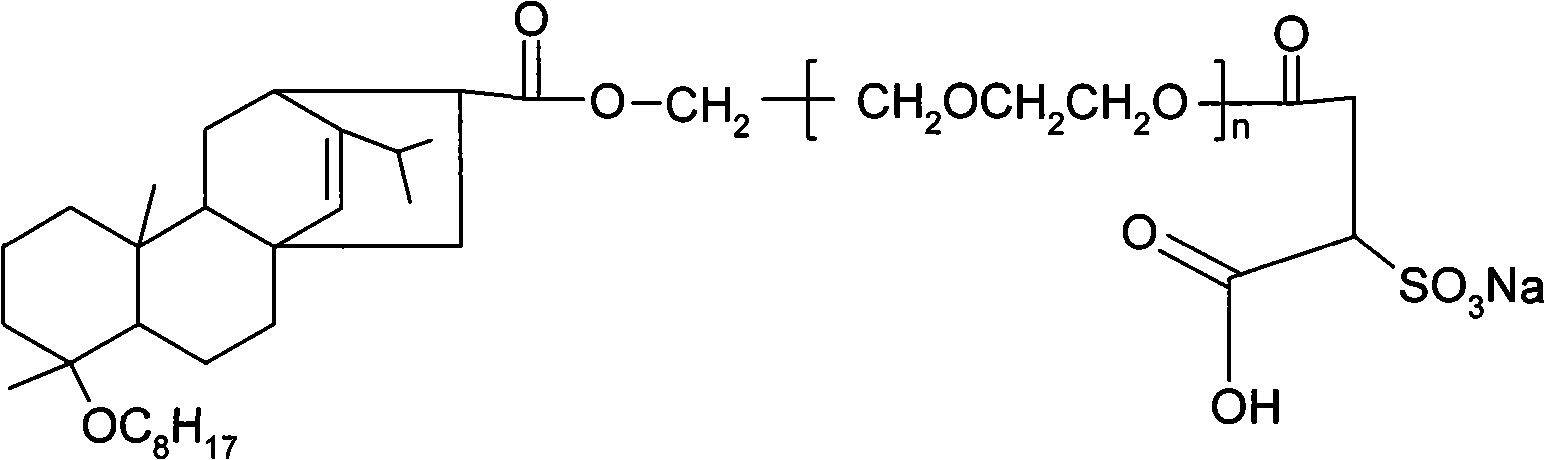

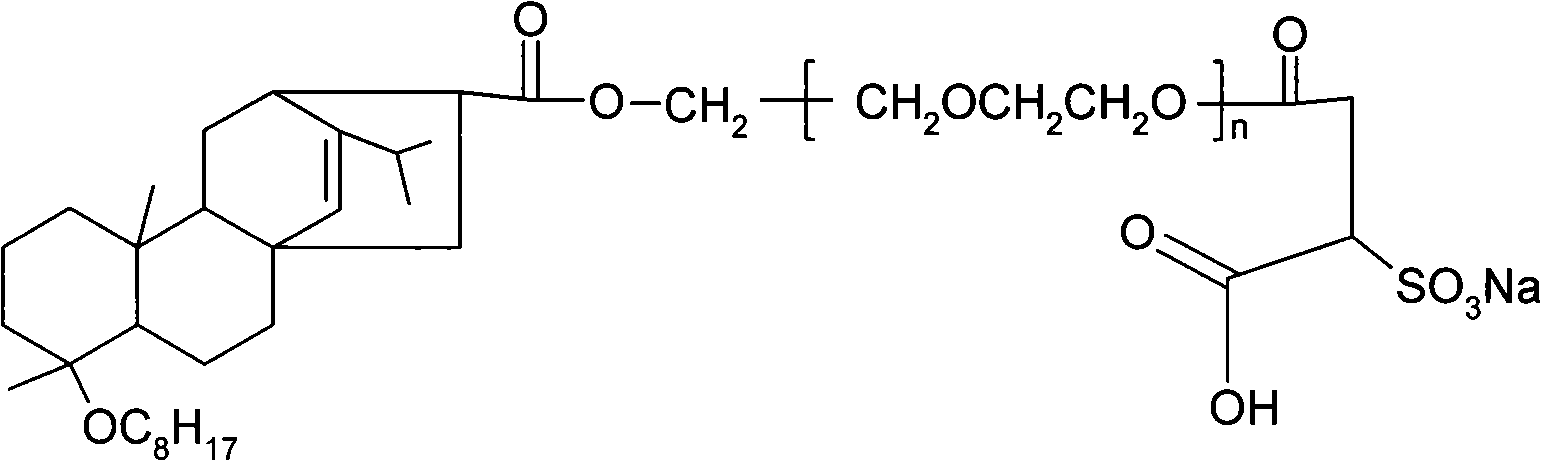

Gum rosin base emulsifier and preparation and use thereof

A rosin-based and emulsifier technology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve problems affecting the performance of rosin ester emulsions, not environmentally friendly products, environmental pollution, etc., to maintain performance , increase compatibility, reduce the effect of plasticization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

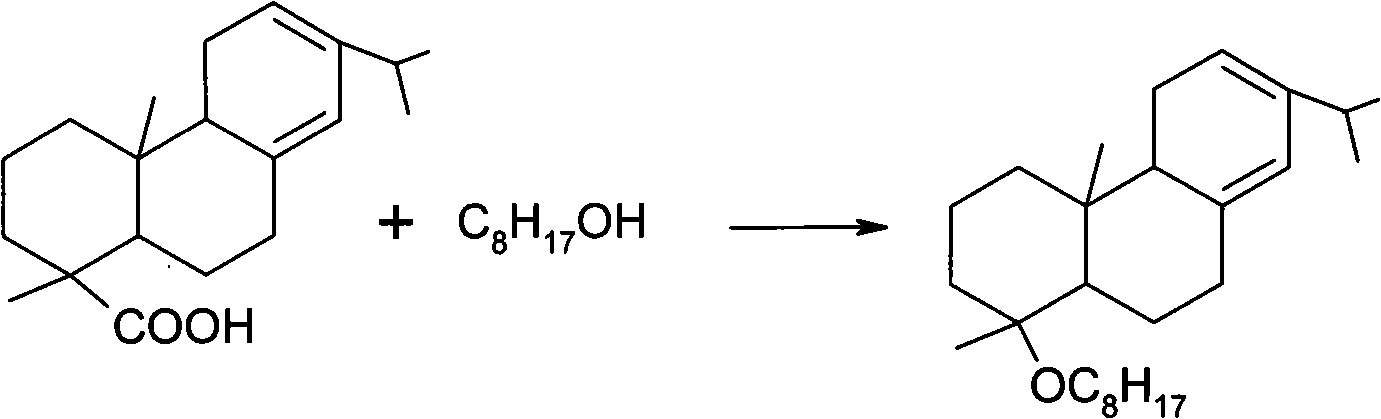

[0033] The first step is to put 600 grams of gum rosin and 1.2 grams of zinc oxide into the reaction bottle, add 260 grams of n-octanol dropwise when heated to 230 ° C, then keep warm and reflux for 5 hours, then raise the temperature to 270 ° C for 8 hours, and vacuum for 1 hour , make rosin ester, and the acid value measured by sampling is 12mgKOH / g;

[0034] In the second step, the temperature is lowered to 240°C, 0.1 g of hydroquinone is added to the rosin ester, and 128 g of acrylic acid is added dropwise. It is advisable that there is no reflux. After the drop is completed, react for 2 hours, and then pass carbon dioxide for 30 minutes to obtain acrylic acid. sex rosin esters;

[0035] The third step is to lower the temperature to 200°C, add 350 grams of polyethylene glycol PEG200 and 1.5 grams of zinc oxide to the acrylic modified rosin ester, slowly raise the temperature to 250°C for 26 hours, and collect 31.1 grams of generated water to obtain a rosin-based surface a...

Embodiment 2

[0038] The first step is to drop 1000 grams of gum rosin and 1 g of zinc oxide into the reaction bottle, add 300 grams of isooctyl alcohol dropwise when heated to 120 ° C, and react for 10 hours to obtain rosin ester, and the acid value is 28.9 mgKOH / g measured by sampling;

[0039] In the second step, 0.13 grams of hydroquinone was added to the rosin ester, 13 grams of acrylic acid was added dropwise, and the addition reaction was carried out at 120° C. for 2 hours to obtain an acrylic acid-modified rosin ester;

[0040] In the third step, the temperature is raised to 150° C., 108 grams of polyethylene glycol PEG600 and 5 g of zinc oxide are added to the acrylic modified rosin ester, and the condensation reaction is performed for 20 hours to obtain a rosin-based surfactant;

[0041] The fourth step is to lower the temperature to 60°C, add 17.8 grams of maleic anhydride to the rosin-based surfactant, perform an esterification reaction for 8 hours, then add 16.3 grams of sodium ...

Embodiment 3

[0043] The first step is to put 1000 grams of gum rosin into the reaction bottle, add 1000 grams of iso-octanol and 1000 grams of n-octanol dropwise when heated to 280 °C, and react for 15 hours to obtain rosin ester. The acid value is 9 mgKOH / g measured by sampling ;

[0044] In the second step, the temperature was lowered to 260° C., 0.9 gram of hydroquinone was added to the rosin ester, 600 grams of acrylic acid was added dropwise, and the addition reaction was carried out for 5 hours to obtain the acrylic acid-modified rosin ester;

[0045] In the third step, 2530 grams of polyethylene glycol PEG1500 was added to the acrylic acid-modified rosin ester, and condensation reaction was carried out at 260° C. for 30 hours to obtain a rosin-based surfactant;

[0046] The fourth step is to add 220 grams of maleic anhydride to the rosin-based surfactant, perform esterification reaction at 260°C for 10 hours, then add 2.2 grams of sodium bisulfite, and perform a conjugate reaction a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com