Polymerized resin 2-glycidyl ester epoxy resin and method for producing the same

A technology of glyceride epoxy resin and polymerized rosin, applied in the field of epoxy resin, can solve the problems of poor oxidation resistance, direct application limitation, easy crystallization of rosin, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

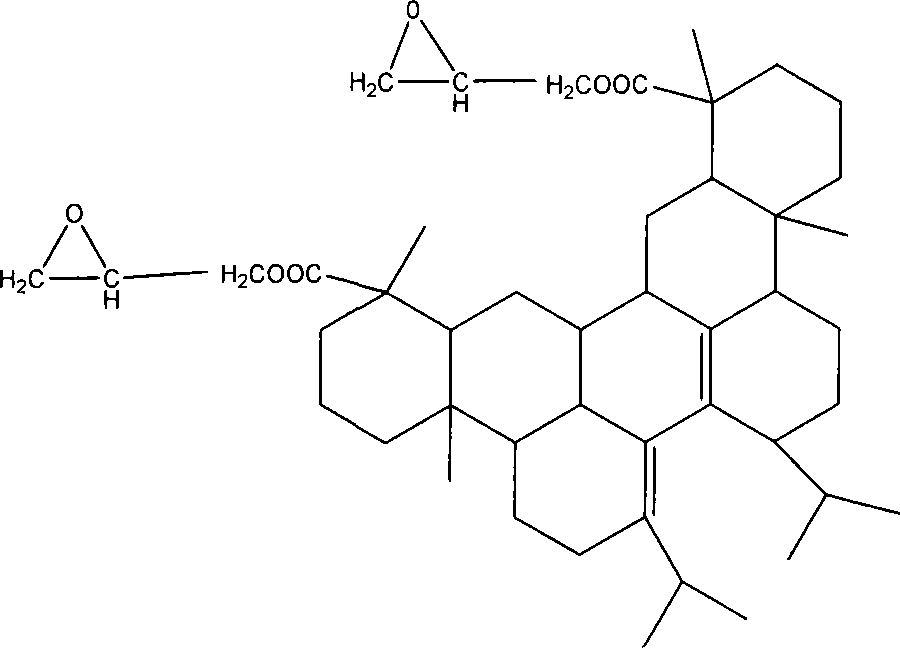

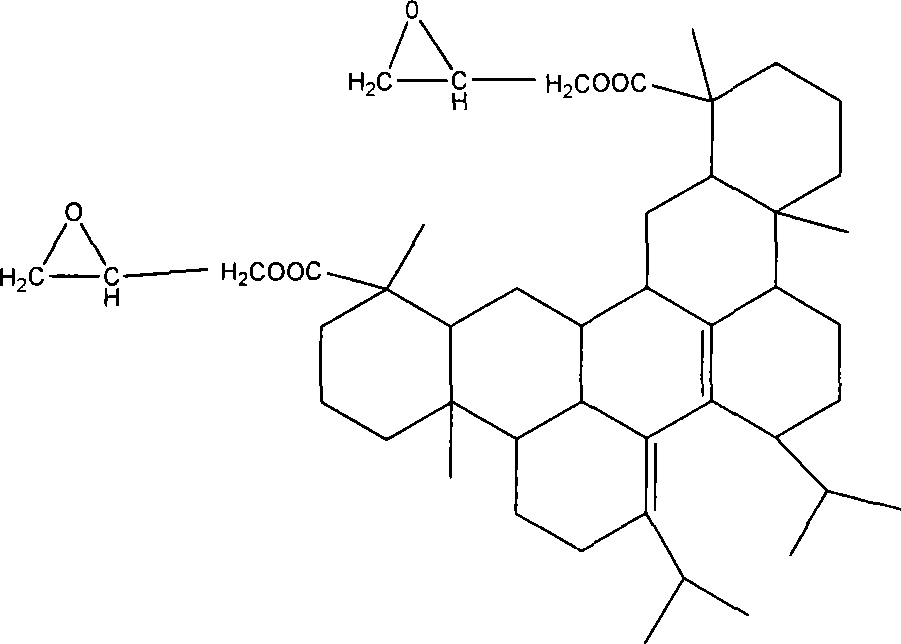

Image

Examples

Embodiment 1

[0018] Add 100 grams of polymerized rosin and 70 grams of epichlorohydrin into a four-necked flask equipped with a thermometer, a stirrer and a condenser, stir and heat up to 90 ° C, add 0.1 grams of sodium hydroxide, and the reaction time is 5 hours. Cool to 40°C, add 80 grams of toluene, add 10 grams of sodium hydroxide, control the temperature below 70°C, react for 2 hours, filter, wash the filtrate with water until there are no halogen ions, dry, and remove the toluene under reduced pressure to obtain the product polymerized rosin Diglycidyl ester epoxy resin. The polymerized rosin diglycidyl ester epoxy resin has the following characteristics: it is yellow transparent viscous liquid to solid at room temperature, and there is 1726cm in the infrared spectrogram. -1 、1243cm -1 、1144cm -1 、1103cm -1 、910cm -1 、850cm -1 and 760cm -1 Etc. characteristic absorption; epoxy value is 0.15-0.3 epoxy equivalent / 100g resin; softening point is 30-90°C.

Embodiment 2

[0020] Add 100 grams of polymerized rosin and 70 grams of epichlorohydrin into a four-necked flask equipped with a thermometer, a stirrer and a condenser, stir and heat up to 100° C., add 0.2 grams of tetramethylammonium chloride, and the reaction time is 4.5 hours. After the reaction, cool to 50°C, add 75 grams of benzene, add 15 grams of sodium hydroxide, control the temperature below 75°C, react for 2.5 hours, filter, wash the filtrate with water until there are no halogen ions, dry, and remove the solvent under reduced pressure to obtain The product is polymerized rosin diglycidyl ester epoxy resin.

Embodiment 3

[0022] Add 100 grams of polymerized rosin and 90 grams of epichlorohydrin into a four-necked flask equipped with a thermometer, a stirrer and a condenser, stir and heat up to 105° C., add 0.1 grams of tetramethylammonium chloride, and the reaction time is 5 hours. After the reaction, cool to 45°C, add 80 grams of toluene, add 20 grams of sodium hydroxide, control the temperature below 70°C, react for 3 hours, filter, wash the filtrate with water until there are no halogen ions, dry, and remove the toluene under reduced pressure to obtain The product is polymerized rosin diglycidyl ester epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com