Preparation method of tetraglycidyl m-xylene diamine epoxy resin

A technology of m-xylylenediamine epoxy resin and tetraglycidyl, which is applied in the field of preparation of tetraglycidyl m-xylylenediamine epoxy resin, can solve the problem of high viscosity and toxicity of m-xylylenediamine epoxy resin Large size, high cost, etc., to avoid hydrolysis and self-polymerization, reduce the content of organic chlorine, reduce the effect of resin viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

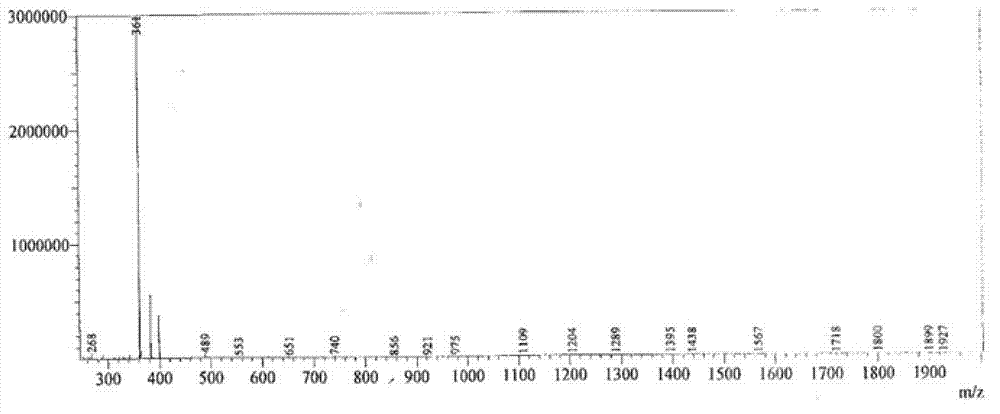

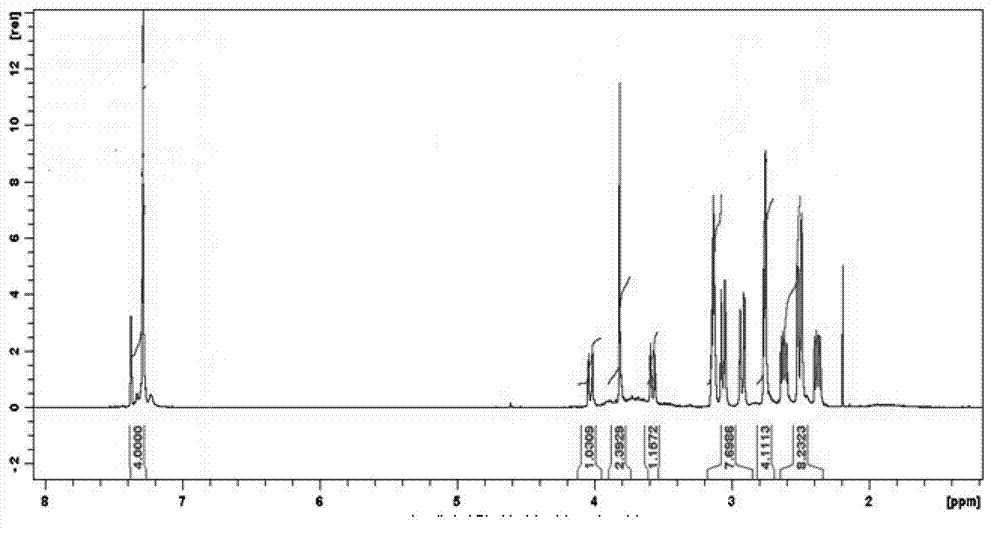

Image

Examples

Embodiment 1)

[0018] The preparation method of the tetraglycidyl m-xylylenediamine epoxy resin of the present embodiment has the following steps:

[0019] ①Put 277.5g of epichlorohydrin (3mol) and 7.20g of deionized water (0.4mol) in sequence into a 1000mL four-necked flask equipped with mechanical stirring, reflux condenser, and thermometer, heat to 45°C, and in 1h Slowly add 27.2 g of m-xylylenediamine (0.2 mol) dropwise, and heat to 58° C. for 8 hours for ring-opening reaction.

[0020] ② Cool down to 45°C, add 66.67g of 48wt% sodium hydroxide solution (containing 32g of sodium hydroxide, 0.8mol) dropwise to the material obtained in step ① within 2h, and continue the ring-closing reaction at 45°C for 2h .

[0021] ③ After the reaction is finished, the epichlorohydrin is recovered by distillation under reduced pressure at a temperature of 60° C. for 1 hour. Then add 170mL of methyl isobutyl ketone and 170mL of water, stir slowly at a temperature of 60°C until completely dissolved, pour ...

Embodiment 2~ Embodiment 4)

[0028] The preparation method of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 1.

[0029] Table 1

[0030] Example 1 Example 2 Example 3 Example 4 m-xylylenediamine 27.2g (0.2mol) 27.2g (0.2mol) 27.2g (0.2mol) 27.2g (0.2mol) Deionized water 7.2g (0.4mol) 7.2g (0.4mol) 7.2g (0.4mol) 7.2g (0.4mol) Epichlorohydrin 277.5g (3mol) 296g (3.2mol) 259g (2.8mol) 277.5g (3mol) The dropping temperature and time of m-xylylenediamine 45℃,1h 30℃,0.5h 50℃,1h 40℃,1h Ring opening reaction temperature and time 58℃,8h 60℃,6h 50℃,4h 45℃,4h alkaline solution 66.67g, 48wt% sodium hydroxide solution 150g, 30wt% potassium hydroxide solution 71g, 45wt% sodium hydroxide solution 64g, 50wt% sodium hydroxide solution Alkali solution dropping temperature and time 45℃,2h 60℃,3h 50℃,3h 55℃,2.5h Ring closing reaction temperature and time 45℃,2h 60℃,1.5h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com