Method for catalytic synthesis of epoxidized soybean oil under carboxylic acid-free condition

A technology of epoxidized soybean oil and soybean oil, which is applied in chemical instruments and methods, catalytic reactions, physical/chemical process catalysts, etc., can solve the problems of low catalytic reaction efficiency and difficulty in obtaining high-quality epoxidized soybean oil, and achieve excellent Catalytic performance, high epoxy value, clean synthesis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

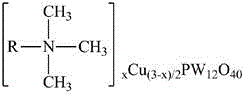

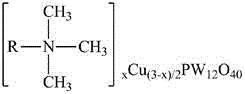

[0017] Catalyst preparation: Weigh 1.6 mmol of cetyltrimethylammonium chloride, 0.7 mmol of copper nitrate and 1 mmol of phosphotungstic acid and dissolve them in 20 ml of deionized water; , first slowly add the cetyltrimethylammonium chloride solution to the phosphotungstic acid solution, and then continue to slowly add the copper nitrate solution to gradually form a white precipitate; after the addition, continue to stir for 0.5 h, and then statically Place and age for 1 h. After the white precipitate is separated by filtration and dried, the molecular formula can be obtained as [(C 16 h 33 )N(CH 3 ) 3 ] 1.6 Cu 0.7 PW 12 o 40 Composite doped phosphotungstate.

Embodiment 2

[0019] The preparation of catalyst: preparation process is the same as embodiment 1, only changes the add-on of cetyltrimethylammonium chloride into 1mmol, and the add-on of copper nitrate is changed into 1 mmol, molecular formula can be obtained as [(C 16 h 33 )N(CH 3 ) 3 ] CuPW 12 o 40 Composite doped phosphotungstate.

Embodiment 3

[0021] Preparation of catalyst: the preparation process is the same as in Example 1, only cetyltrimethylammonium chloride is changed to 2 mmol, and the addition of copper nitrate is changed to 0.5 mmol, and the molecular formula can be obtained as [(C 16 h 33 )N(CH 3 ) 3 ] 2 Cu 0.5 PW 12 o 40 Composite doped phosphotungstate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com