LC-01 type foam concrete foamer

A foamed concrete and foaming agent technology, which is used in the field of concrete additives and high-efficiency air-entraining agents for concrete, can solve the problem that the output of foamed concrete is reduced, the chemical properties of cement and fly ash slurry are not considered, and the foaming agent stays at the foaming multiple. Problems such as the length of foam stabilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] raw material

[0018] (1) NaOH (99.0%, Tianjin) 37.5~38mol

[0019] (2) Succinic acid (industrial product, 95%, Anhui) 1.8~2.4mol

[0020] (3) Borax (industrial product, 95%, Shanghai) 1.9~2.1mol

[0021] (4) Triethanolamine (industrial product, 85%, Xingtai, Hebei) 2~8mol

[0022] (5) Rosin (industrial product, grade two, Guangxi) 18~22mol

[0023] (6) AES (sodium fatty alcohol polyoxyethylene ether sulfate, 70%, Jilin) 28~32mol

[0024] (7) 6501 (coconut oil fatty acid diethanolamide (1:1), 95%, Guangdong) 0~0.1mol

[0025] (8) Hydrogen peroxide (27.5%, industrial product, Shandong) 0~0.1mol

[0026] resolve resolution

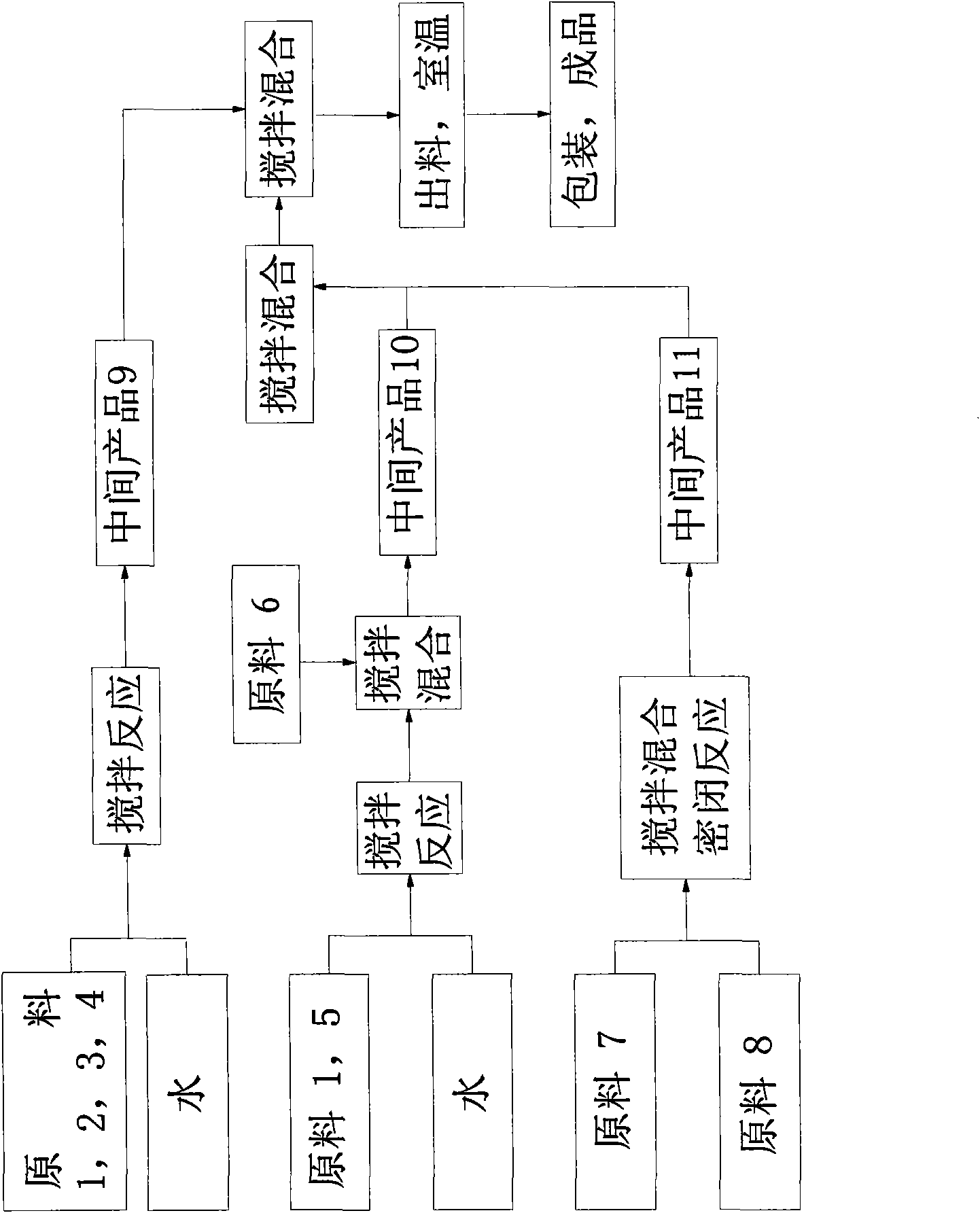

[0027] Mix raw materials 1, 2, 3, and 4 in proportion, add a certain amount of water (soft water or distilled water, the same below) and heat to dissolve, and continue to react for 1 hour to obtain intermediate product 9. Weigh raw materials 1 and 5 in proportion. Material 1 was dissolved in water. Heat raw material 5 to melt it completely,...

Embodiment 2

[0029] The raw material 1 in the embodiment 1 is changed into anhydrous or sodium carbonate decahydrate, calculate their consumption according to the principle that the molar quantity of its neutralized H+ is identical with sodium hydroxide; Adjust accordingly. Other raw materials, quantity and technological condition are constant, can obtain product LC-01 foam concrete blowing agent of the present invention equally. Compared with Example 1, its advantage is that sodium carbonate is relatively cheap, and its active ingredient is easy to determine. The disadvantage is that in the production process of the intermediate product 10, the solution of raw material 1 should be added carefully to prevent "overfilling the pot".

Embodiment 3

[0031] The raw material 2 in Example 1 is changed to malonic acid or adipic acid, and the molar quantity added is the same as that of succinic acid; the amount of make-up water for finally washing the relevant containers should also be adjusted accordingly. Other raw materials, quantity and technological condition are constant, can obtain product LC-01 foam concrete blowing agent of the present invention equally. Compared with succinic acid, malonic acid is currently more expensive; adipic acid needs to be imported, and its price is comparable to succinic acid, but the effect of products with the same solid content is not as good as succinic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com