Method for extracting and separating ginger essential oil and ginger oil resin enriched in gingerol

A technology for ginger oleoresin and ginger essential oil is applied in the field of extracting and separating ginger essential oil and ginger oleoresin rich in gingerol, which can solve the problems of complex process route flow, increasing use of separators, affecting solute solubility, etc., and shortening the technological process. , The effect of reducing equipment investment and reducing plant occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

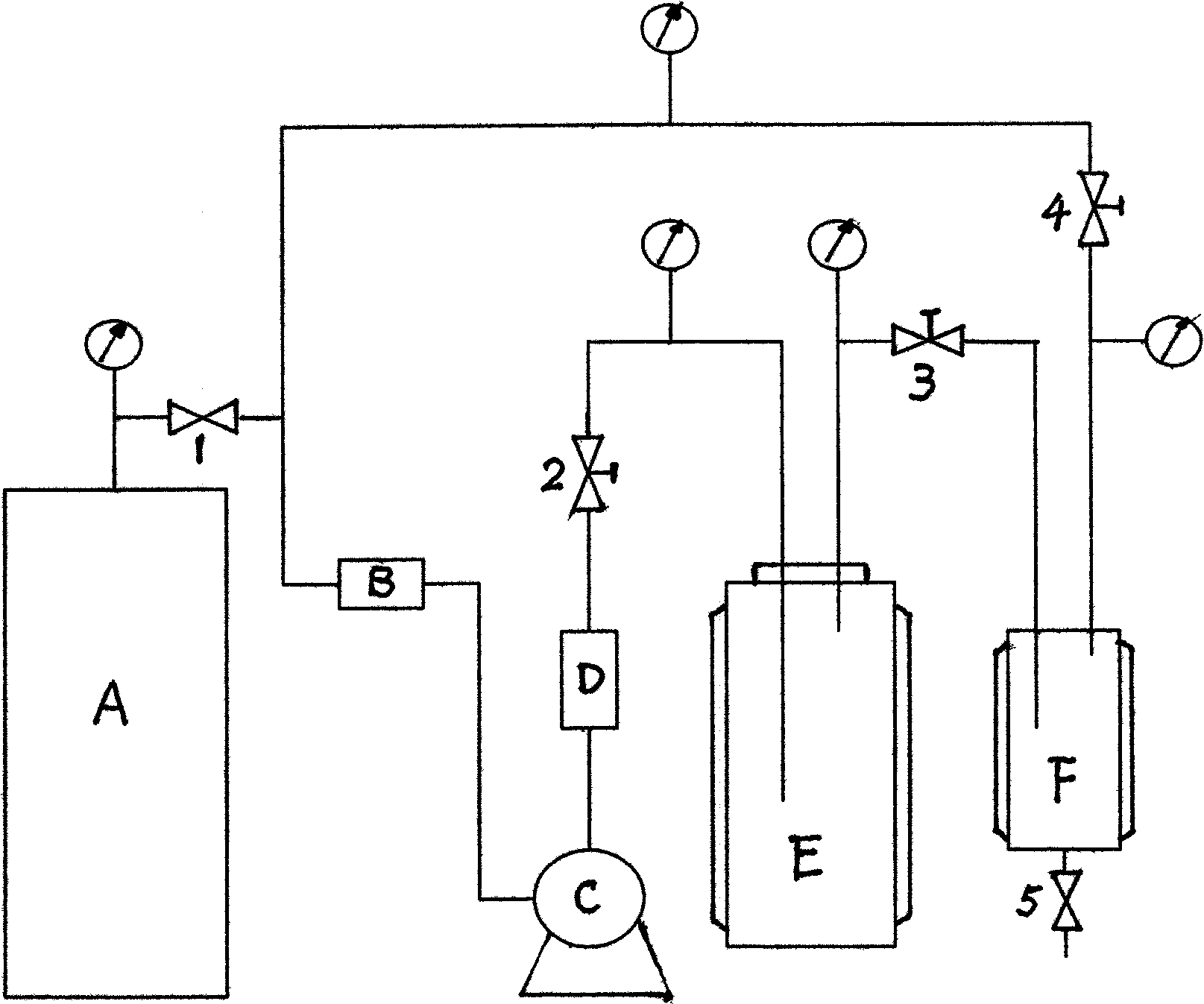

Embodiment 1

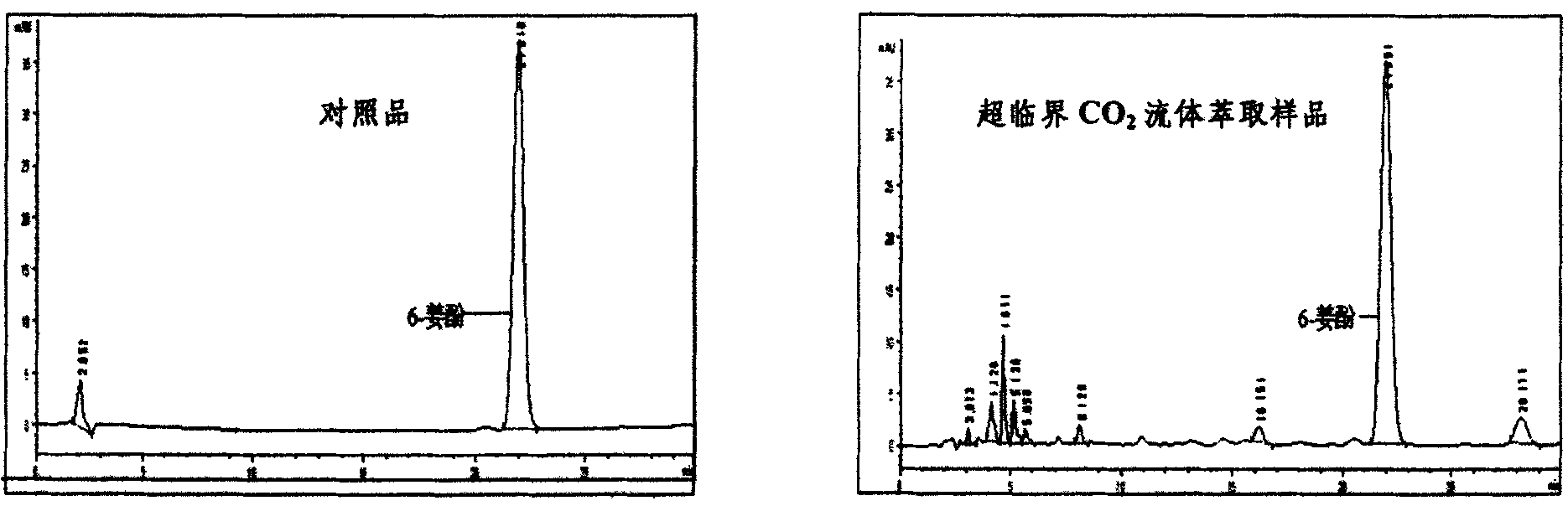

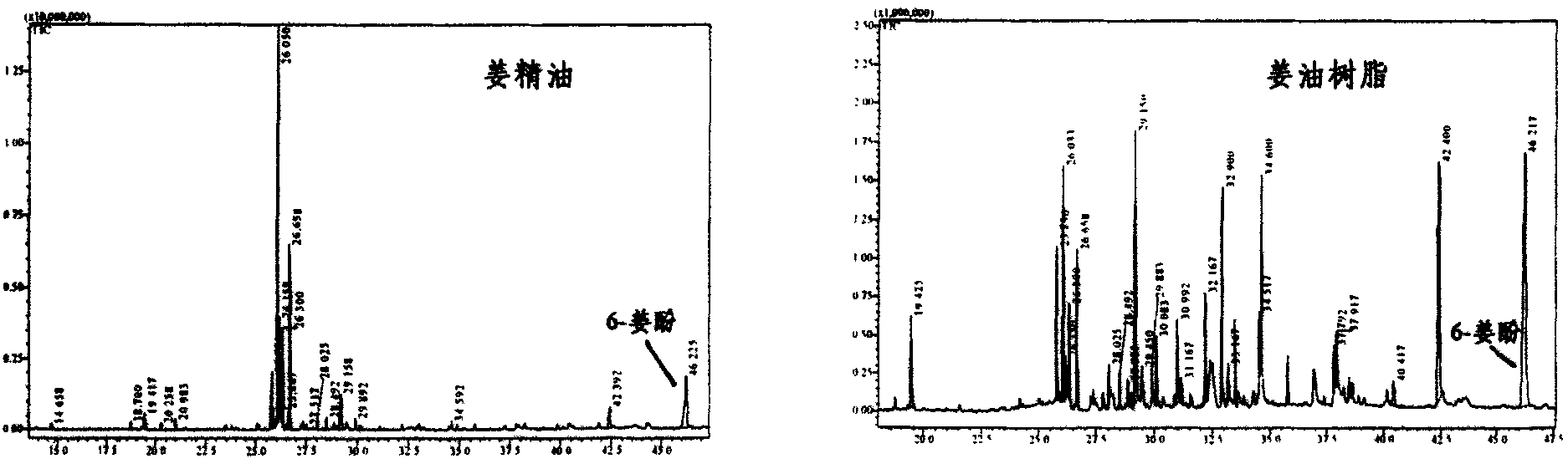

[0017]10 kg of pulverized ginger powder is loaded into a 25-liter extraction kettle, the first stage of extraction, the extraction pressure is 9 MPa, the extraction temperature is 40 ° C, the separation pressure is 5.5 MPa, the separation temperature is 45 ° C, after 45 minutes of extraction, the separation tank F valve 5 Ginger essential oil is released in the middle, and after dehydration treatment, 310 grams are obtained, which is a yellow transparent oily liquid with good fluidity. Adjust the pressure of the extraction kettle to 22MPa, the extraction temperature is 50°C, keep the same pressure and temperature of the separation kettle, continue the extraction for 50 minutes, release the ginger oleoresin from the valve 5 of the separation kettle F, and obtain 182 grams after dehydration, which is brown-yellow fat shape, poor fluidity. As determined by high performance liquid chromatography, the content of 6-gingerol in ginger essential oil is 0.8%, and the content of 6-ginge...

Embodiment 2

[0019] Put 10 kg of pulverized ginger powder in a 25 liter extraction kettle, extract in the first stage, extraction pressure 12MPa, extraction temperature 50°C, separation pressure 6MPa, separation temperature 55°C, after extraction for 60 minutes, from the separation kettle F valve 5 Release ginger essential oil, obtain 351 grams after dehydration treatment, be yellow-red transparent oily liquid, fluidity is good. Adjust the pressure of the extraction kettle to 26MPa, the extraction temperature is 60°C, keep the same pressure and temperature of the separation kettle, continue the extraction for 50 minutes, release the ginger oleoresin from the valve 5 of the separation kettle F, and obtain 163 grams after dehydration treatment, which is a brown-yellow viscous Thick fat, poor fluidity. As determined by high performance liquid chromatography, the content of 6-gingerol in ginger essential oil is 1.9%, and the content of 6-gingerol in ginger oleoresin is 25.1%.

Embodiment 3

[0021] Put 10 kg of pulverized ginger powder in a 25-liter extraction tank, extract in the first stage, extraction pressure 16 MPa, extraction temperature 65 ° C, separation pressure 6.5 MPa, separation temperature 60 ° C, after extraction for 50 minutes, from the separation tank F valve 5 Ginger essential oil is released in the middle, and after dehydration treatment, 297 grams are obtained, which is a yellow-red transparent oily liquid with good fluidity. Adjust the pressure of the extraction kettle to 32MPa, the extraction temperature is 70°C, keep the same pressure and temperature of the separation kettle, continue the extraction for 50 minutes, release the ginger oleoresin from the valve 5 of the separation kettle F, and obtain 115 grams after dehydration treatment, which is a brown-yellow viscous Thick fat, poor fluidity. As determined by high performance liquid chromatography, the content of 6-gingerol in ginger essential oil is 2.6%, and the content of 6-gingerol in gi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com