Method for reclaiming rosin and terebinth using resin plant residue waste liquor

A waste liquid recovery and turpentine oil technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problem that the residue and waste liquid in rosin factories are difficult to be fully utilized, and achieve the effect of cost saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

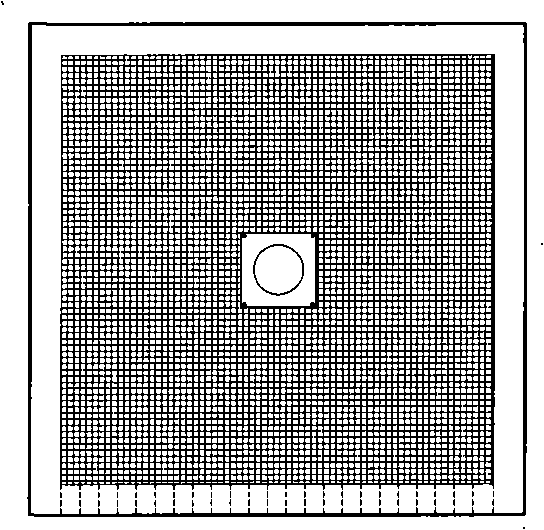

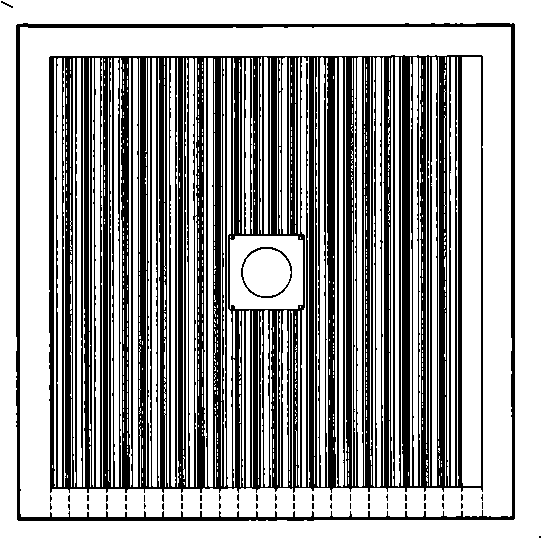

Image

Examples

example 1

[0012] A method for recovering rosin and turpentine by using residue waste liquid from a rosin factory, the steps are: (1) dissolving: carry out in a dissolving pot with a sieve plate, a slag discharge port and a liner type filter device. First add 0.2 tons of water, then add 0.4 tons of turpentine, 0.001 tons of oxalic acid, then put 0.6 tons of raw materials (waste liquid from the rosin factory) into the dissolving pot, open the emptying gate valve of the condensing and reflux device, and then introduce live air to heat the materials in the pot , the temperature rises to 80-90°C, then close the live steam and keep it for 5 minutes. Open the gate valve of the discharge port, and send the mixed fat liquid into the static pot. (2) Static preparation: the mixed fat liquid obtained in the dissolving process is input into the static pot, and after standing for 40 minutes, the drain valve is opened to discharge most of the water slag to obtain the static fat liquid. (3) Clarificat...

example 2

[0014] The treatment method of the sewage discharged by the existing technology of the rosin factory: its steps are: 1. After the rosin production sewage enters the sewage tank, it can start the pressure filtration operation of the 4th step of embodiment 1 after accumulating to a certain amount, and the filtrate obtained is transparent Oxalic acid liquid; 2. Pump the oxalic acid liquid to the high-level tank of dissolved water, put it into the dissolving process quantitatively, and reduce the consumption of oxalic acid to 50% of the original amount at the same time. The oxalic acid liquid is recycled and not discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com