Apparatus and method for separating tert-butanol and water using batch fractionating and pervaporation

A technology of pervaporation and tert-butanol, which is applied in separation methods, chemical instruments and methods, separation/purification of hydroxyl compounds, etc., can solve the problems of low yield, achieve high purity, wide application range, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

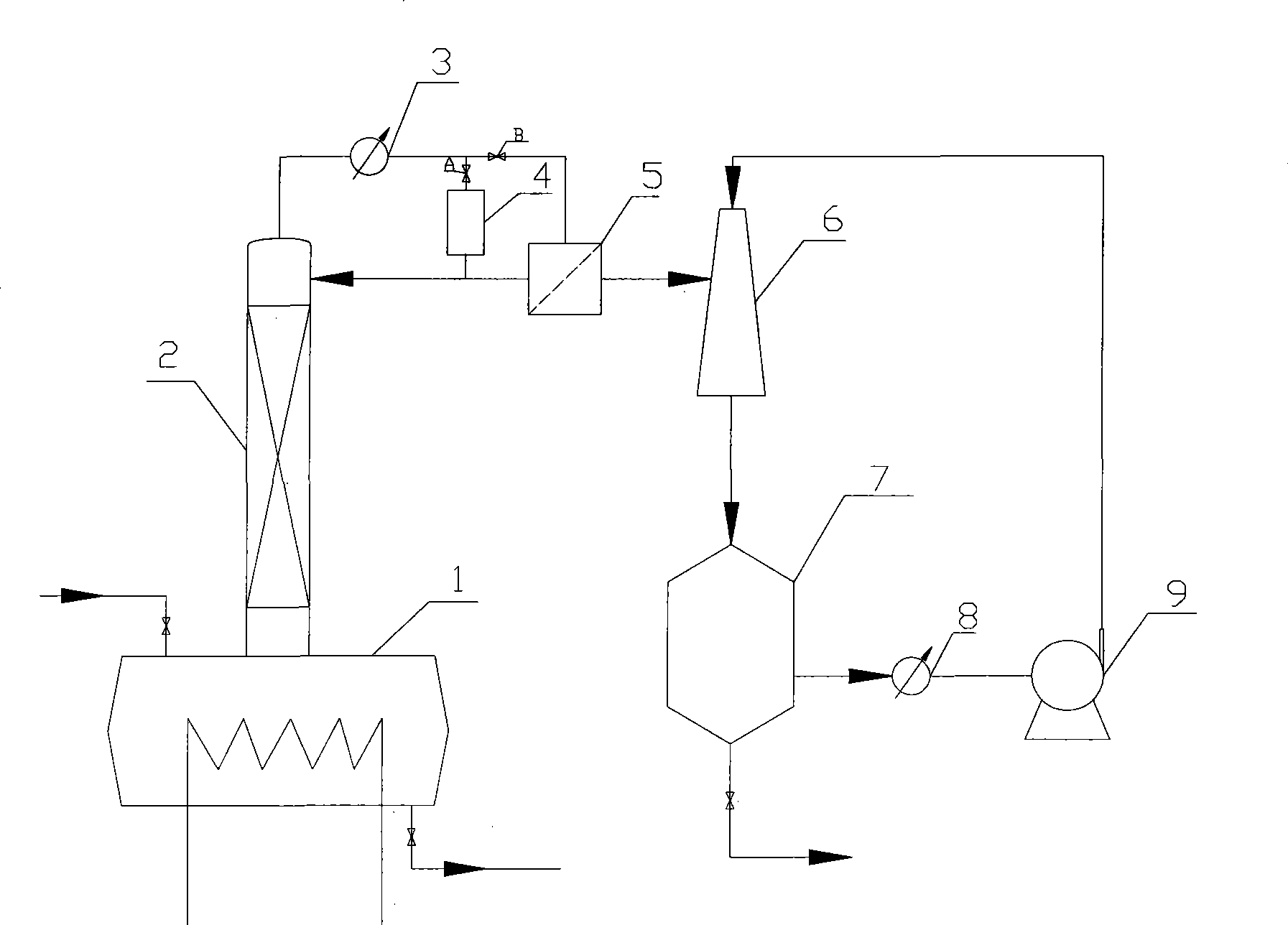

[0022] Such as figure 1 The diagram of the device is shown. Put 600ml of tert-butanol-water solution containing 80% tert-butanol into the still of the batch rectification tower to check the tightness of the system. First close the valve B at the outlet of the condensate at the top of the tower, open the valve A, pass the cooling water into the condenser at the top of the tower, turn on the heating power supply to heat the tower kettle, and perform the full reflux operation after there is reflux at the top of the tower, and the total reflux is 1.5 Hours, the gas-liquid balance in the tower was stable, and the temperature of the condensate at the top of the tower was stable at 62.5°C. Switch the condensate outlet valve, close valve A, open valve B, so that the azeotrope of tert-butanol-water enters the membrane separator, and further dehydration and separation are carried out in the membrane separator, and the tert-butanol concentrated on the intercepted side enters the rectifi...

Embodiment 2

[0024] Such as figure 1 The diagram of the device is shown. Put 600ml of tert-butanol-water solution containing 88% tert-butanol into the still of the batch rectification tower to check the tightness of the system. First close the valve B at the outlet of the condensate at the top of the tower, open the valve A, pass the cooling water into the condenser at the top of the tower, turn on the heating power supply to heat the tower kettle, and perform the full reflux operation after there is reflux at the top of the tower, and the total reflux is 1.5 Hours, the gas-liquid balance in the tower was stable, and the temperature of the condensate at the top of the tower was stable at 62.5°C. Switch the condensate outlet valve, close valve A, open valve B, so that the azeotrope of tert-butanol-water enters the membrane separator, and further dehydration and separation are carried out in the membrane separator, and the tert-butanol concentrated on the intercepted side enters the rectifi...

Embodiment 3

[0026] The diagram of the device is shown in Figure 3. Put 600ml of tert-butanol-water solution containing 92% tert-butanol into the still of the batch distillation tower to check the tightness of the system. First close the valve B at the top condenser, open the valve A, pass cooling water into the top condenser, turn on the heating power supply to heat the tower kettle, and perform full reflux operation after there is reflux at the top of the tower, full reflux for 1.5 hours , the gas-liquid balance in the tower is stable, and the temperature of the condensate at the top of the tower is stable at 62.5°C. Switch the condensate outlet valve, close valve A, open valve B, so that the azeotrope of tert-butanol-water enters the membrane separator, and further dehydration and separation are carried out in the membrane separator, and the tert-butanol concentrated on the intercepted side enters the rectification tower Circulation in the tower, the permeation side uses a water jet pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com