Dye filling apparatus for hydraulics flow visualization test and test method

A flow display and filling device technology, which is applied in the field of hydraulic testing, can solve the problems of low dye injection efficiency, extended time for repeated injection of dye solution, and inability to inject dye solution at multiple points at the same time, so as to ensure the test effect , Improve the effect of injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

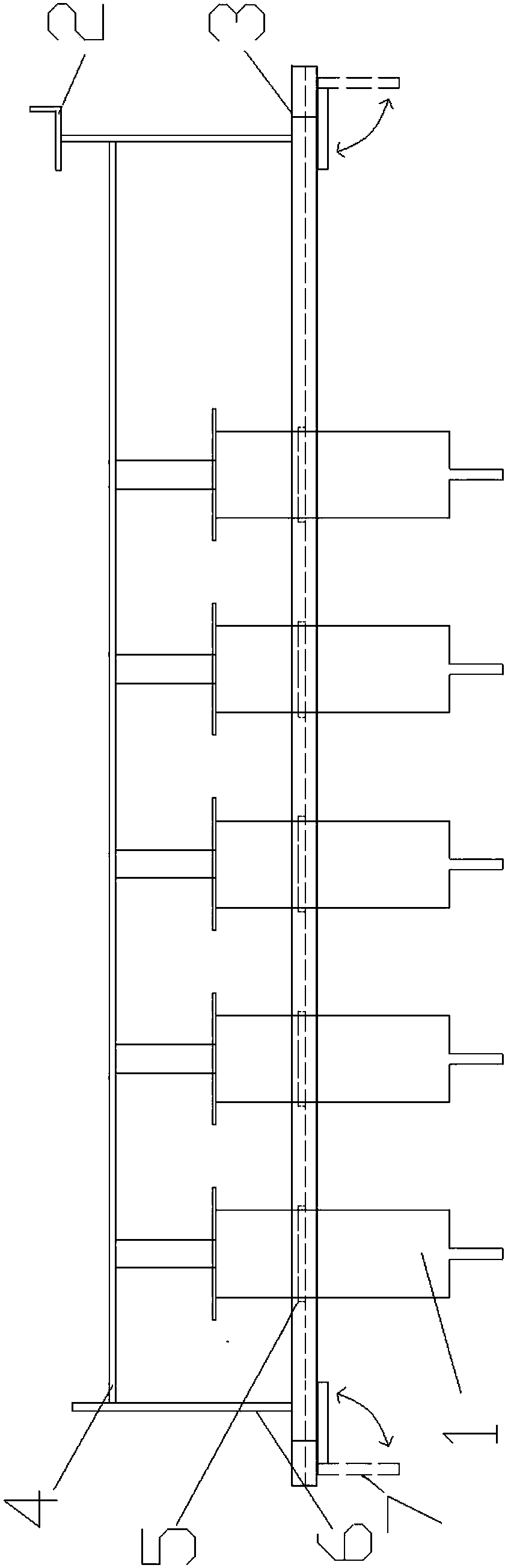

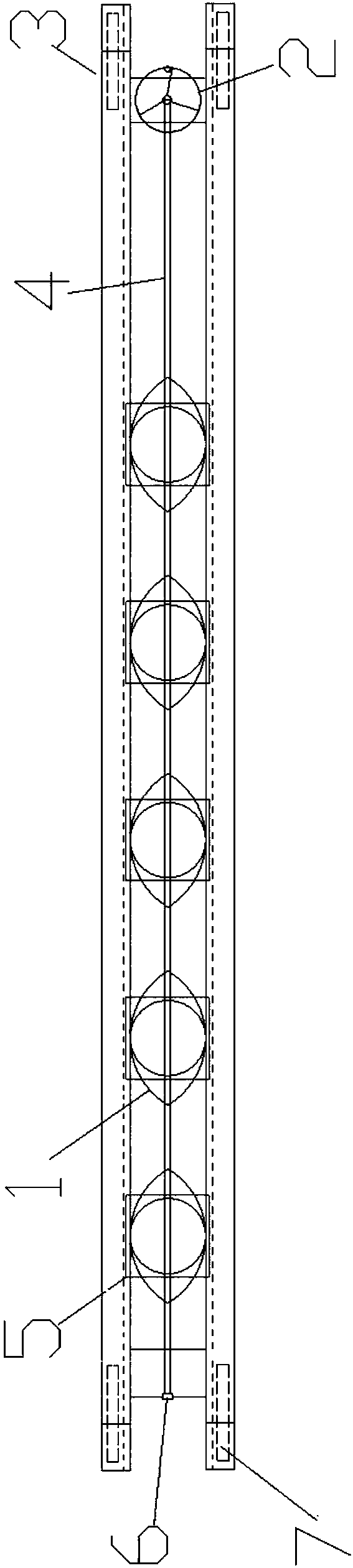

[0027] In this embodiment, as Figures 1 to 2 Said, a dye filling device for hydraulic flow display test, including a plurality of syringes 1, a lifting wheel 2, a telescopic rack 3, a pressure rod 4, a moving slider 5, an upper bracket 6, a lower bracket Bracket 7; the telescopic bent frame 3 includes two horizontally symmetrically arranged telescopic support transverse plates and a connecting block connecting both ends of the telescopic support transverse plate; the inner side of the telescopic support transverse plate has corresponding horizontal grooves; the moving The slider 5 is horizontally clamped on the barrel of the syringe syringe 1, and the two ends of the moving slider 5 are located in the groove; the connecting blocks at both ends of the telescopic bracket 3 are respectively provided with upper brackets 6 , and a lifting runner 2 is set on the upper bracket 6 at one end; the two ends of the pressure rod 4 that is fixedly connected to the piston handle of the syri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com