Device and method for spraying wall paint with gradient colors

A technology of spraying device and wall paint, applied in spraying device, liquid spraying device, construction and other directions, can solve problems such as poor painting effect, and achieve the effect of saving manpower and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

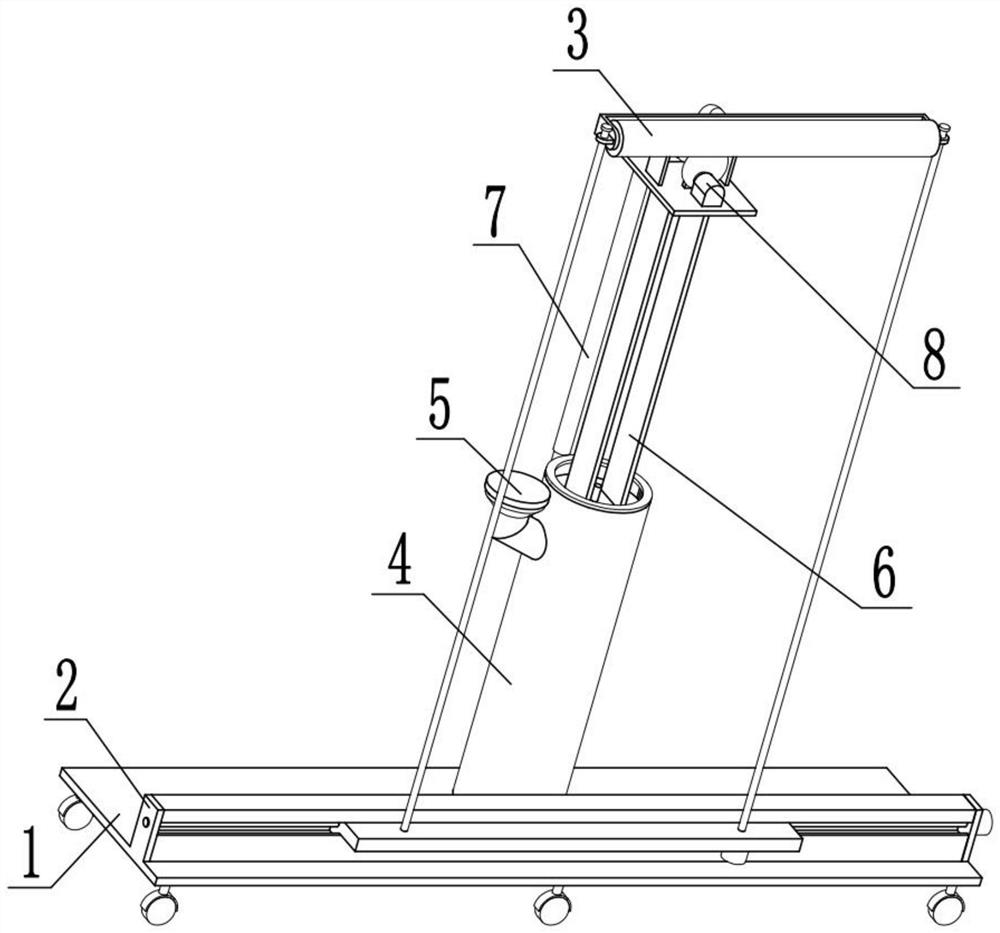

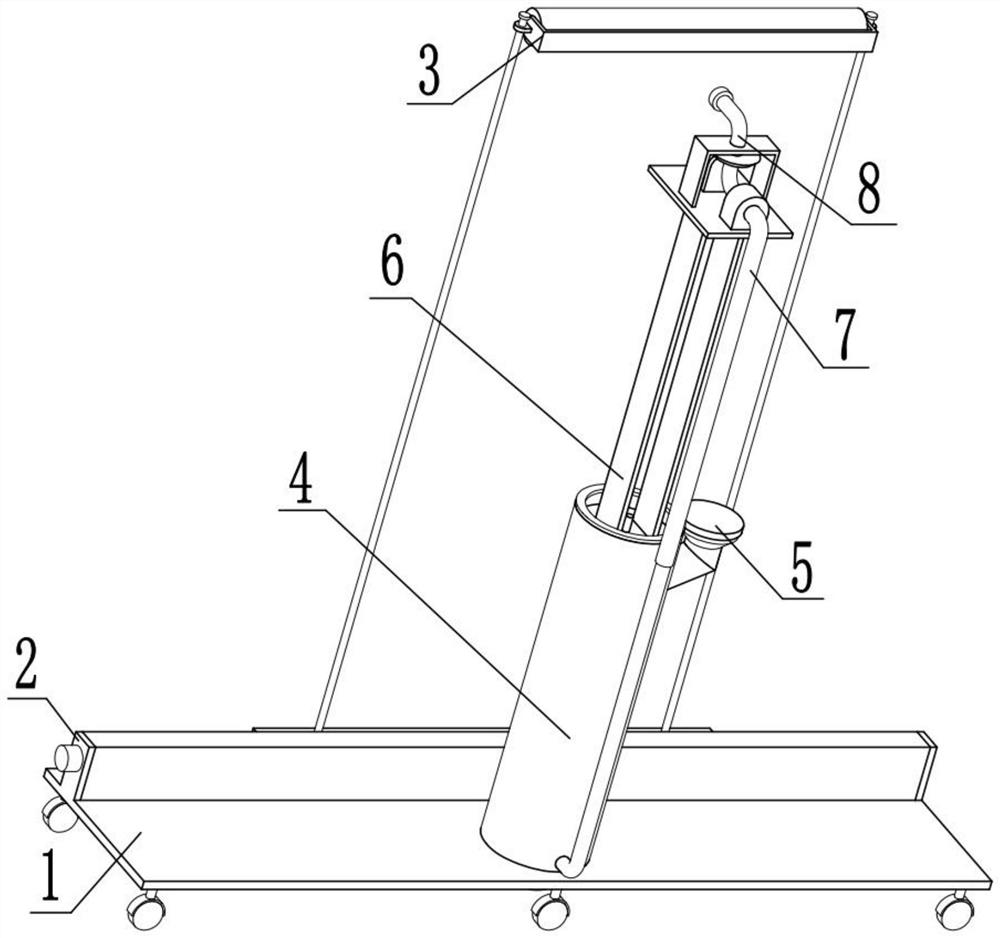

[0030] like Figure 1-6 As shown, a gradient color wall paint spraying device includes a bearing base member 1, a lateral moving device 2, a wall surface rolling device 3, a dye storage device 4, an adding flaring device 5, a lifting and lowering bearing member 6, and a dye transfer device 7 and a dye spraying device 8, the bearing base member 1 is connected with a lateral moving device 2, the lateral moving device 2 is connected with a wall rolling brush device 3, and the bearing base member 1 is connected with a dye storage Device 4, the dye storage device 4 is fixedly connected with an adding flaring device 5, the dye storage device 4 is connected with a lifting bearing member 6, and the lifting bearing member 6 is fixedly connected with a dye transfer device 7 , the dye transfer device 7 is slidably connected with the dye storage device 4 , the dye storage device 4 is connected with a dye injection device 8 , and the dye injection device 8 is slidably connected with the dy...

specific Embodiment approach 2

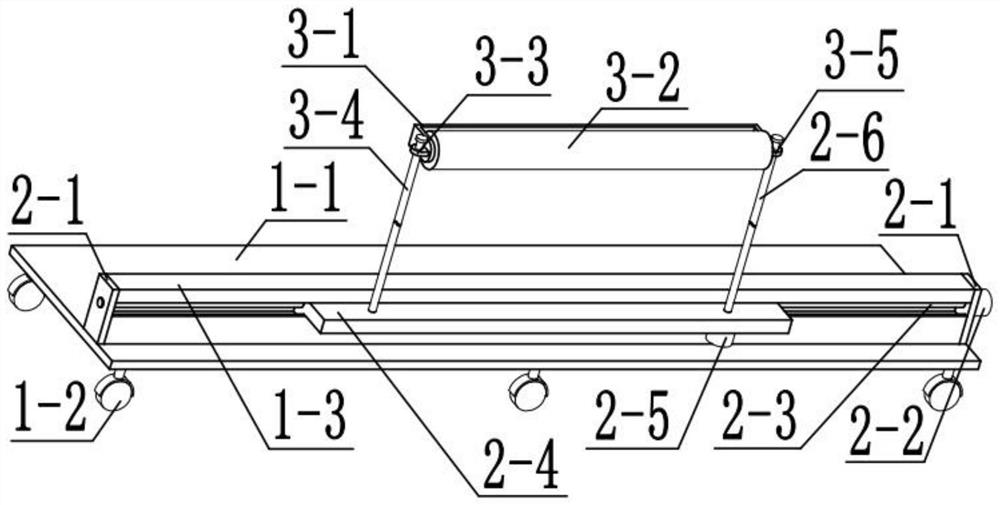

[0032] like Figure 1-6 As shown, the load-bearing base component 1 includes a supporting vehicle plate 1-1, universal wheels 1-2 and traversing slides 1-3, and a plurality of universal wheels are fixedly connected under the supporting vehicle plate 1-1. Wheel 1-2, a plurality of universal wheels 1-2 are equipped with self-locking devices, and the top of the supporting vehicle plate 1-1 is fixedly connected with a traverse slideway 1-3;

[0033] The supporting vehicle plate 1-1 plays the role of bearing connection, utilizes the contact between multiple universal wheels 1-2 and the ground to facilitate the movement of the device, and the multiple universal wheels 1-2 are equipped with self-locking devices, When it is necessary to spray gradient dyes on the wall, the self-locking device of multiple universal wheels 1-2 is opened to realize the fixation of the device, and the traversing slideway 1-3 can provide sliding for the traversing supporting plate 2-4 space so that it can...

specific Embodiment approach 3

[0035] like Figure 1-6 As shown, the lateral moving device 2 includes a side fixing plate 2-1, a motor I2-2, a traversing screw 2-3, a traversing pallet 2-4, a motor II2-5 and a lifting screw 2-6 , the side fixing plate 2-1 is provided with two, and the two side fixing plates 2-1 are respectively fixedly connected to the two ends of the traversing slideway 1-3, and one of the side fixing plates 2-1 is fixedly connected with The motor I2-2, the output shaft of the motor I2-2 is fixedly connected with a traversing lead screw 2-3, the other end of the traversing lead screw 2-3 is rotatably connected with another side fixed plate 2-1, and the traversing supporting plate 2-4 is slidingly connected in the traversing slideway 1-3, the traversing supporting plate 2-4 is connected with the traversing lead screw 2-3 through screw transmission, and the lower part of the traversing supporting plate 2-4 is fixedly connected with the motor II2- 5. The output shaft of the motor II2-5 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com