Button dyeing machine

A technology for dyeing machines and buttons, applied in the field of button dyeing machines, can solve the problems of uneven dyeing, high labor intensity of workers, and low button dyeing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

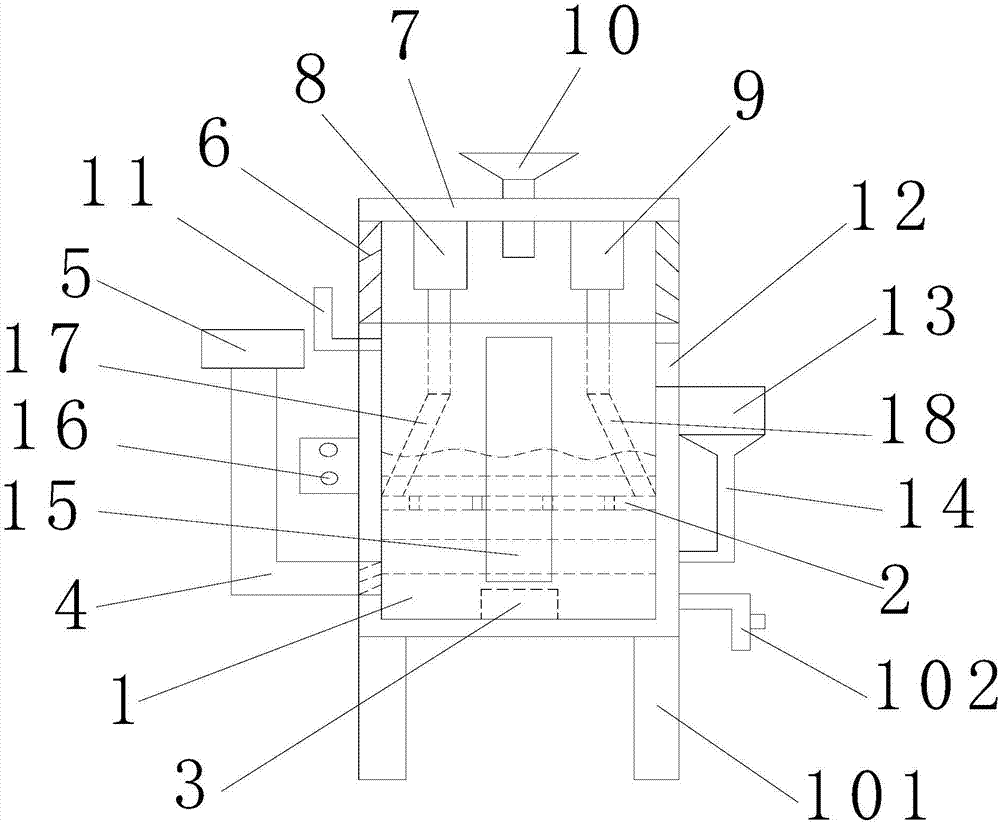

[0022] refer to figure 1 , a button dyeing machine of the present invention comprises a dyeing vat 1, a material sieve 2, an electric heater 3, an air intake pipe 4, an air pump 5, a mounting frame 6, a top plate 7, a first cylinder 8, a second cylinder 9, a lower hopper 10, Dye injection pipe 11, discharge port 12, draining box 13, conduit 14, observation window 15, first connecting rod 17 and second connecting rod 18, the inner side of the dyeing vat 1 is slidingly provided with a horizontally arranged material sieve 2 , the inner bottom of the dyeing vat 1 is provided with an electric heater 3, the lower side of the dyeing vat 1 is connected with an air intake pipe 4, and the outer end of the air intake pipe 4 is provided with an air pump 5, and the two sides of the upper part of the dyeing vat 1 Two symmetrically arranged mounting frames 6 are fixedly arranged, and a horizontally arranged top plate 7 is fixedly connected between the upper ends of the two mounting frames. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com