Field jet fabric dyeing method and field jet fabric dyeing system

A fabric dyeing and jetting technology, which is applied in dyeing, textiles and papermaking, spray/jet textile material treatment, etc., can solve problems that cannot be solved in dyeing processing, and achieve saving of dye consumption and water consumption, proper dyeing amount, and water washing The effect of less water consumption

Pending Publication Date: 2021-11-02

NEWTECH TEXTILE TECH DEV SHANGHAI

View PDF8 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If these problems are not solved, the industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

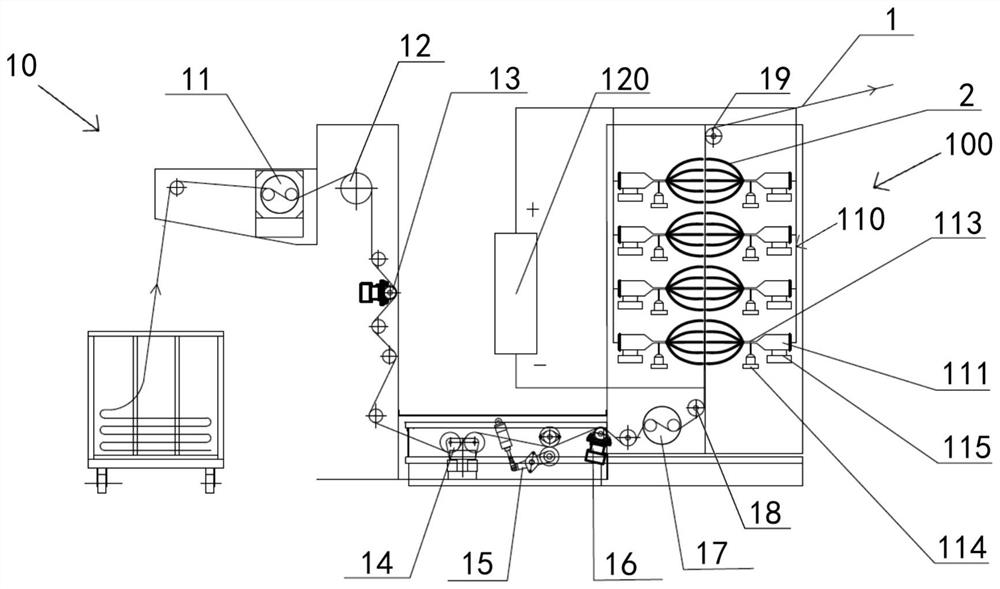

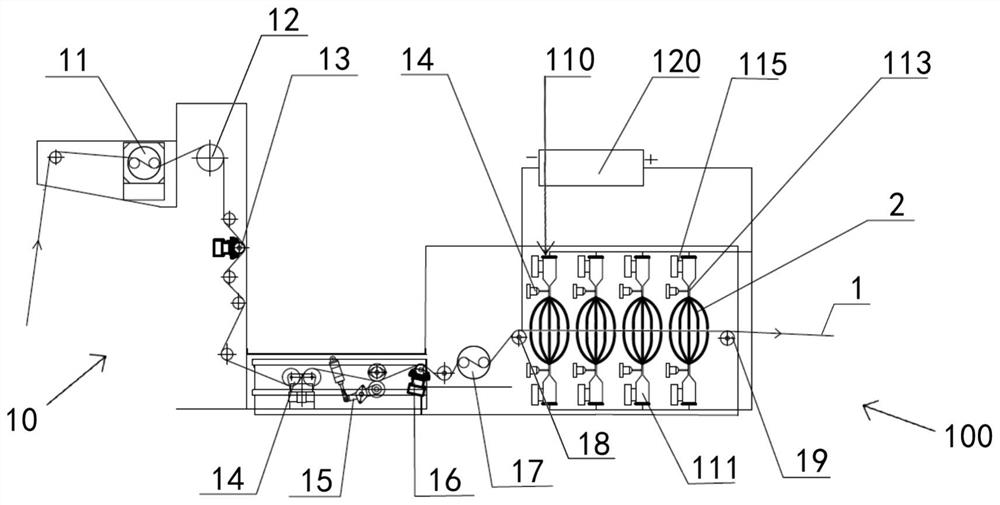

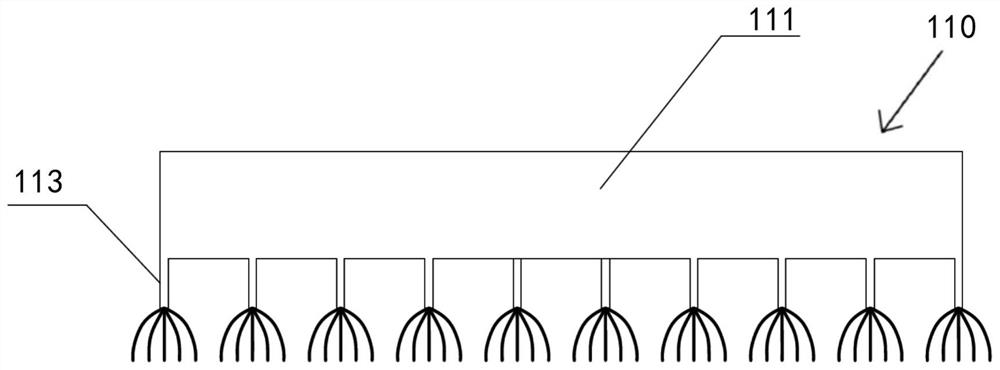

The invention relates to a field jet fabric dyeing method. The method comprises the following steps that a fabric is guided to pass through a dyeing assembly through a guiding system; fabric is dyed through a dyeing mechanism and a voltage source; the dyeing mechanism comprises a dye storage mechanism and a dye injection mechanism; the dyeing mechanism comprises a needle tube part, an airflow supply part and a dye supply part; the needle tube part is provided with an airflow channel and a dye channel, and the airflow channel is in fluid communication with the airflow supply part; the dye channel is in fluid communication with the dye storage mechanism; the voltage source applies a voltage to the dyeing mechanism such that an electrostatic field is generated between the dyeing mechanism and the fabric and a voltage is generated, the dye is output from the dye channel under the action of a dye supply pressure and/or a negative pressure of the air flow and forms droplets, and the droplets are charged by the voltage, after spallation, an electrified fog drop group is formed under the action of electric field force, moves towards the fabric and is adsorbed on the fabric, so that the fabric is dyed. The invention further relates to a field jet fabric dyeing system.

Description

technical field [0001] The present disclosure relates to the field of fabric printing and dyeing, and more specifically, to a field jet fabric dyeing method and a field jet fabric dyeing system. Background technique [0002] Textile dyeing is a technique in which dyes are used to dye and process dyed objects. At present, the most common dyeing technology is pad dyeing, that is, the process of pad dyeing solution-drying-fixation-washing. The greatest pressure on dyeing processing is environmental pressure, such as the substitution of banned dyes, the treatment of three wastes, water and energy saving, monitoring and control of ecological standards of products, etc. If these problems are not solved, the industry bottleneck of dyeing processing cannot be solved. Contents of the invention [0003] The purpose of the present disclosure is to propose a field jet fabric dyeing method and a field jet fabric dyeing system, which can overcome at least one defect in the prior art. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06B1/00D06B1/02D06P1/38D06P1/39D06P1/16D06P3/66D06P3/54D06P5/00

CPCD06B1/00D06B1/02D06P1/38D06P1/39D06P1/16D06P3/66D06P3/54D06P5/00

Inventor 钟博文田龙刘新刚

Owner NEWTECH TEXTILE TECH DEV SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com