Polyvinylidene fluoride mixed matrix membrane with photocatalytic performance as well as preparation and application thereof

A polyvinylidene fluoride and mixed matrix membrane technology, applied in the field of membrane separation, can solve the problems of polyvinylidene fluoride membrane membrane fouling, etc., achieve the effects of high hydrophilicity, improve self-cleaning ability, and reduce membrane fouling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the photocatalytic performance polyvinylidene fluoride mixed matrix film of the self-adhesive method in the present invention comprises the following steps:

[0041] 1) Preparation of casting solution: Add porogens polyvinylpyrrolidone (PVP) and polyvinylidene fluoride (PVDF) to N,N-dimethylacetamide (DMAc) and stir at 30-80°C for 8 -18h, the casting solution was obtained after standing still for defoaming;

[0042] Wherein, the mass ratio of porogen and polyvinylidene fluoride is (0.5-3.5):(14-20);

[0043]2) Preparation of polyvinylidene fluoride mixed matrix membrane by delayed phase inversion method: scrape the casting solution on a glass plate with a thickness of 100-260 μm, and place it in a mixture of ethanol and water at a volume ratio (2.4-3.5): (1.8-2.8) The phase separation is carried out in the gel bath of 14-30 ℃, and the SnO in the gel bath 2 -Cu 2 The amount of O added is 0.1-1.0 g / L to obtain a polyvinylidene fluoride mixed m...

Embodiment 1

[0049] This example is used to prepare polyvinylidene fluoride mixed matrix membrane, and the specific preparation method is as follows:

[0050] 1) Dissolve PVP and PVDF in DMAc at a mass ratio of 2.0:18, and stir at 60°C for 10 hours until fully dissolved, and then stand for degassing for 6 hours to obtain a casting solution;

[0051] 2) Squeegee-coat the casting solution on the glass plate with a thickness of 250 μm;

[0052] 3) Immerse the glass plate with the membrane solution in a mixture of ethanol and deionized water at a volume ratio of 2.8:2.3 at 15°C for phase separation, in which the SnO in the gel bath 2 -Cu 2 O addition amount is 0.5g / L;

[0053] 4) Transfer the phase-separated membrane to soak in deionized water to remove excess solvent, and then store it in clean deionized water to obtain a polyvinylidene fluoride mixed matrix membrane, which is denoted as M1 ultrafiltration membrane.

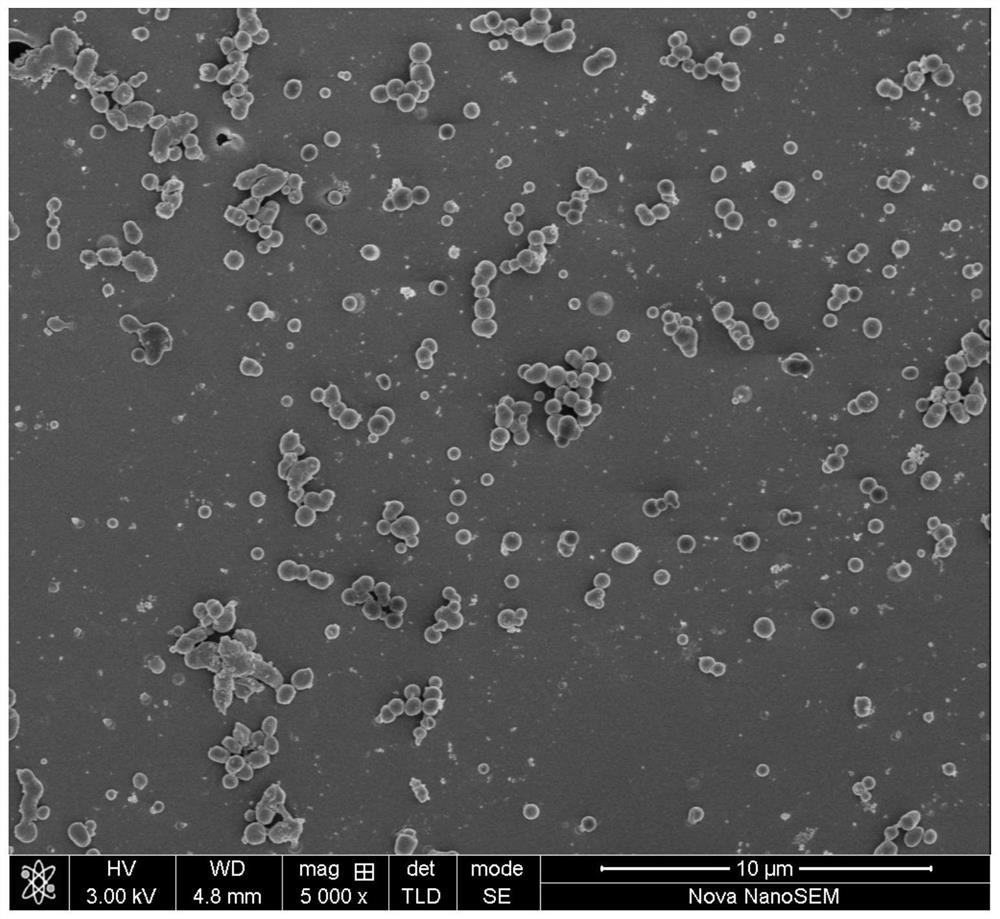

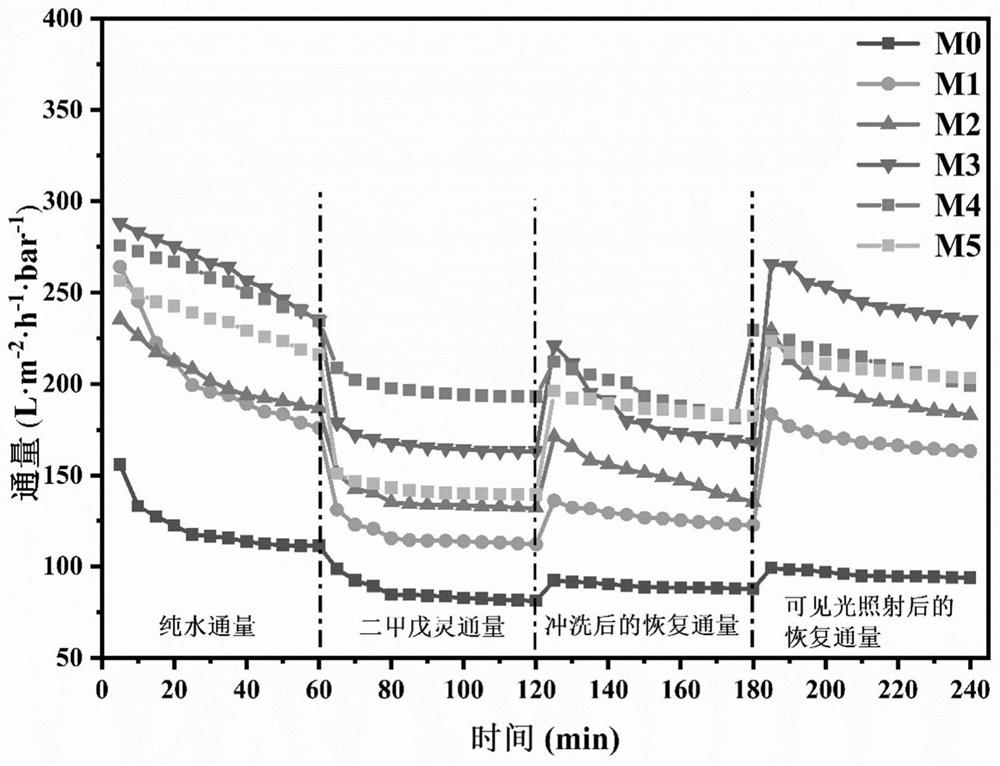

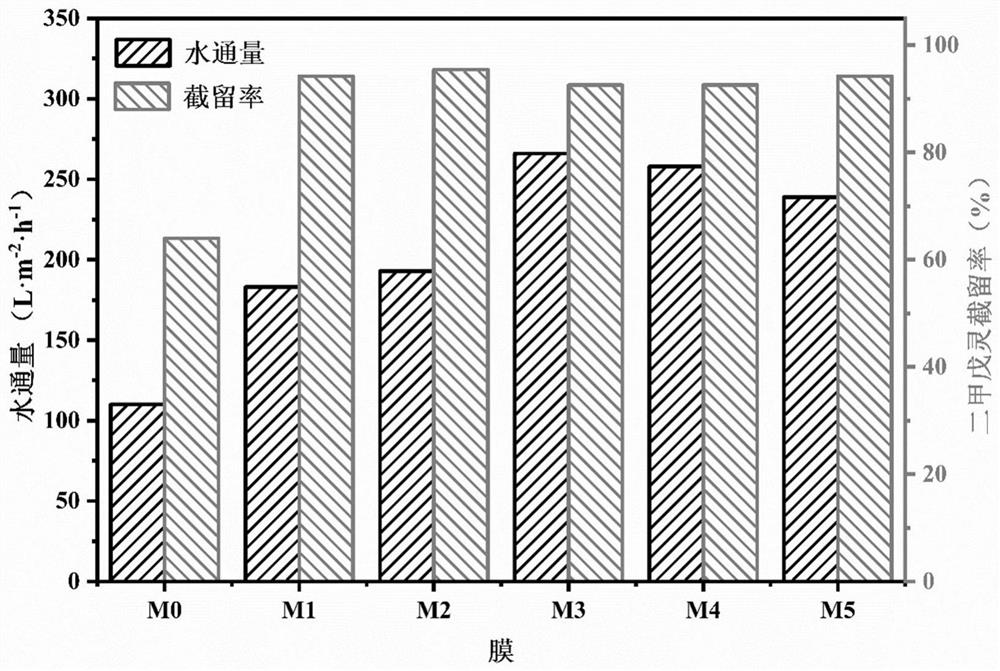

[0054] The obtained M1 ultrafiltration membrane was characterized by sur...

Embodiment 2

[0056] This example is used to prepare polyvinylidene fluoride mixed matrix membrane, and the specific preparation method is as follows:

[0057] 1) Dissolve PVP and PVDF in DMAc at a mass ratio of 2.5:15, and stir at 70°C for 10 hours until fully dissolved, and then stand for defoaming for 10 hours to obtain a casting solution;

[0058] 2) Squeegee-coat the casting solution on the glass plate with a thickness of 150 μm;

[0059] 3) Immerse the glass plate with the film solution in a mixture of ethanol and deionized water at a volume ratio of 3.2:2.5 at 20°C for phase separation, in which the SnO in the gel bath 2 -Cu 2 O addition amount is 0.7g / L;

[0060] 4) Transfer the phase-separated membrane to soak in deionized water to remove excess solvent, and then store it in clean deionized water to obtain a polyvinylidene fluoride mixed matrix membrane, which is designated as an M2 ultrafiltration membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com