Preparation and application of phosphorus-doped graphite carbon nitride/ferroferric oxide composite material

A technology of graphitic carbon nitride and iron tetroxide, which is applied in chemical/physical processes, oxidized water/sewage treatment, special compound water treatment, etc. low rate issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

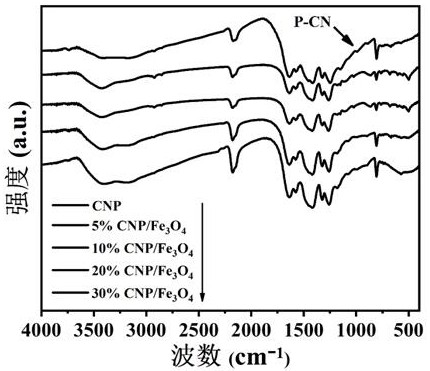

[0028] (1) Preparation of CNP: Grind urea (10g, 0.17mol) and dipotassium hydrogen phosphate (0.87g, 5mmol) thoroughly and mix them in a crucible with a lid, heat in a muffle furnace at a heating rate of 2.3°C / min Calcined at 500°C for 2~5h, cooled to room temperature, dissolved in distilled water to form a 1g / L solution, ultrasonicated intermittently at 20000~25000 Hz (interval 1~2h, total ultrasonic 3 h), centrifuged, Washing and drying afforded a pale yellow solid labeled CNP.

[0029] (2) CNP / Fe 3 o 4 Preparation of composite materials: 1 g of CNP and 0.027 g of FeCl 3 •6H 2 O was dissolved in 64 ml of ethylene glycol solution to form a light yellow solution, then 3 ml of hydrazine hydrate was added and stirred for 30 min to form a brownish yellow suspension, and the suspension was transferred to a 100 ml polytetrafluoroethylene-lined stainless steel reactor, React at 200 °C for 10 h, centrifuge, wash with deionized water and ethanol, and dry in a vacuum oven at 70 °C f...

Embodiment 2

[0032] (1) Preparation of CNP: Grind urea (10 g, 0.17 mol) and dipotassium hydrogen phosphate (0.87 g, 5 mmol) thoroughly and mix them in a crucible with a lid, and heat up at a rate of 2.3 °C / min in a muffle furnace Heating to 500°C, calcining for 2~5h, cooling to room temperature, adding it into distilled water and dissolving it to form a 1 g / L solution, ultrasonication at 20000~25000 Hz (interval time 1~2h, total ultrasonication 3 h), Centrifugation, washing, and drying afforded a pale yellow solid labeled CNP.

[0033] (2) CNP / Fe 3 o 4 Preparation of composite materials: 1 g of CNP and 0.054 g of FeCl 3 •6H 2 O was dissolved in 64 ml ethylene glycol solution to form a light yellow solution, then added 6 ml hydrazine hydrate and stirred for 30 min to form a brownish yellow suspension, and the suspension was transferred to a 100 ml polytetrafluoroethylene-lined stainless steel reactor, React at 200 °C for 10 h, centrifuge, wash with deionized water and ethanol, and dry i...

Embodiment 3

[0036] (1) Preparation of CNP: Grind urea (10 g, 0.17 mol) and dipotassium hydrogen phosphate (0.87 g, 5 mmol) thoroughly and mix them in a crucible with a lid, and heat up at a rate of 2.3 °C / min in a muffle furnace Heating to 500°C, calcining for 2~5h, cooling to room temperature, dissolving it in distilled water to form a 1 g / L solution, ultrasonication at 20000~25000 Hz (interval 1~2h, total ultrasonication 3 h), Centrifugation, washing, and drying afforded a pale yellow solid labeled CNP.

[0037] (2) CNP / Fe 3 o 4 Preparation of composite materials: 1 g of CNP and 0.108 g of FeCl 3 •6H 2 O was dissolved in 64 ml of ethylene glycol solution to form a light yellow solution, then 12 ml of hydrazine hydrate was added and stirred for 30 min to form a brownish yellow suspension, and the suspension was transferred to a 100 ml polytetrafluoroethylene-lined stainless steel reaction kettle, in React at 200 °C for 10 h, centrifuge, wash with deionized water and ethanol, and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com