Quantum dot modified titanium dioxide-based photo-anode, solar cell and preparation method

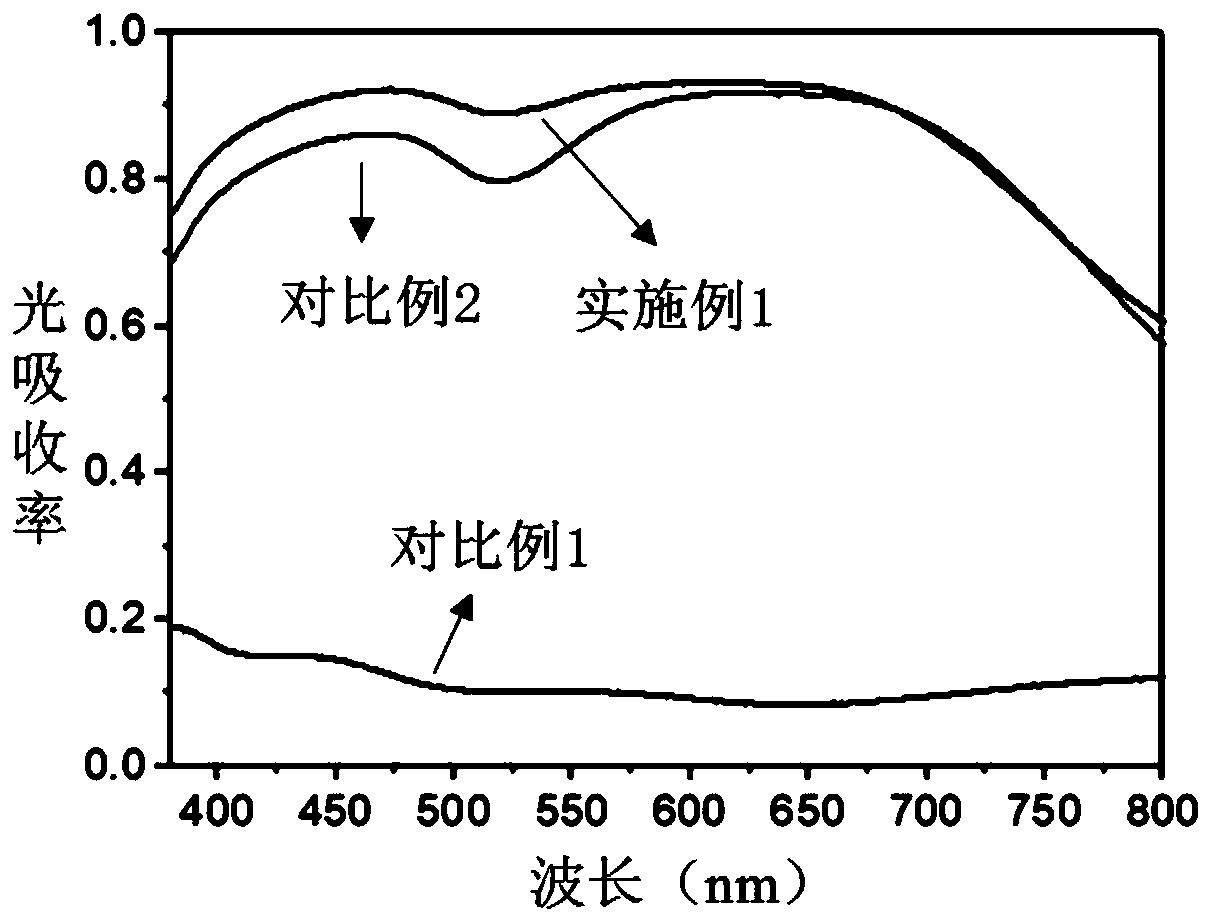

A technology of titanium dioxide and quantum dots, which is applied in the field of solar cells and its preparation, quantum dots modifying titanium dioxide-based photoanodes, and can solve problems such as quantum dots are easy to dissolve, fall off the electrolyte, and the service life of photoanodes is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a preparation method for obtaining the quantum dot-modified titanium dioxide-based photoanode in the above embodiments, and the preparation method includes the following steps.

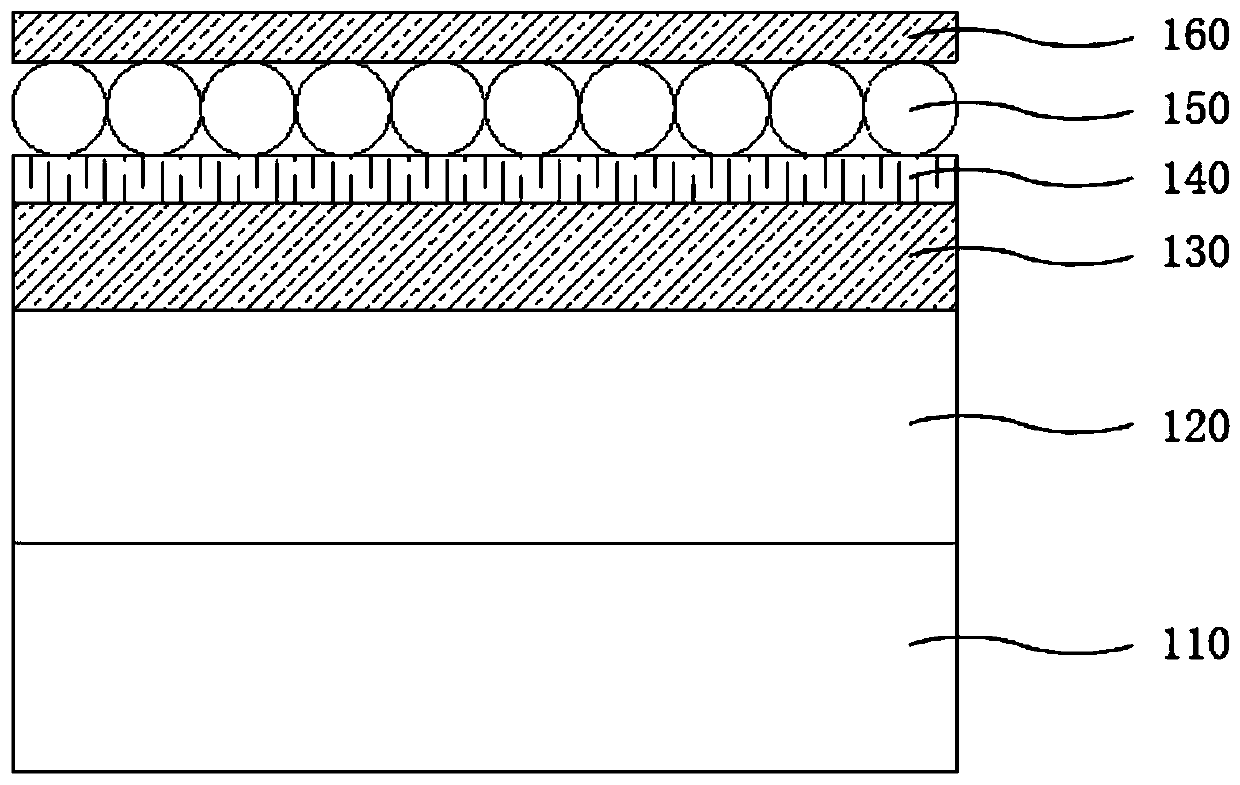

[0046] Step S1, forming a metal layer on a conductive glass substrate, forming a first titanium dioxide layer on the metal layer, and performing a first annealing treatment to obtain a first titanium dioxide substrate.

[0047] As a specific example, the conductive glass may be FTO conductive glass.

[0048] The method of forming the metal layer may be magnetron sputtering, and the thickness of the metal layer may be 20nm-200nm, for example, the thickness of the metal layer is 100nm.

[0049] As a specific example, gold is selected as the material of the metal layer, the deposition current of the magnetron sputtering process can be controlled to be 35mA, and the deposition time is 225s, so that the deposition of a gold layer with a thickness of about 100nm ca...

Embodiment 1

[0070] 1) Deposit a layer of gold film on the FTO conductive glass with a specification of 15mm*15mm by magnetron sputtering; the deposition current is 35mA, the deposition time is 225s, and the thickness of the obtained gold film is about 100nm.

[0071] 2) Deposit a layer of titanium dioxide film on the above gold film by atomic layer deposition technology, the titanium source is tetraisopropyl titanate, the oxygen source is deionized water, the deposition temperature is 200°C, and the thickness of the obtained titanium dioxide film is about 20nm; then Perform annealing treatment, the annealing temperature is 450°C, and the annealing time is 3h, to obtain the first titanium dioxide substrate.

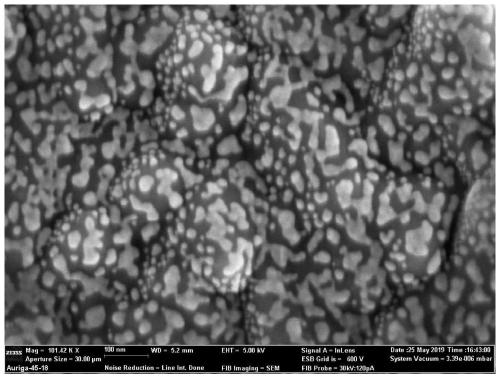

[0072] 3) Soak the obtained first titanium dioxide substrate in an aqueous solution of mercaptopropionic acid with a concentration of 10 mol / L, take it out after 24 hours; then immerse it in CdS x Se 1-x In the aqueous dispersion of quantum dots, take it out after 24 hours, rinse it ...

Embodiment 2

[0076] 1) Deposit a layer of gold film by magnetron sputtering on the FTO conductive glass with a specification of 15mm*15mm; the deposition current is 35mA, the deposition time is 300s, and the thickness of the obtained gold film is about 150nm.

[0077] 2) Deposit a layer of titanium dioxide film on the above gold film by atomic layer deposition technology, the titanium source is tetraisopropyl titanate, the oxygen source is deionized water, the deposition temperature is 200°C, and the thickness of the obtained titanium dioxide film is about 40nm; Perform annealing treatment, the annealing temperature is 500° C., and the annealing time is 2.5 hours, to obtain the first titanium dioxide substrate.

[0078] 3) Soak the obtained first titanium dioxide substrate in an aqueous solution of mercaptopropionic acid with a concentration of 20mol / L, take it out after 15 hours; then immerse it in CdS x Se 1-x In the aqueous dispersion of quantum dots, take it out after 12 hours, rinse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com