Wastewater treatment filtering material, and preparation method and use thereof

A filter material and wastewater treatment technology, which is used in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of reduced adsorption capacity, oxidation, coating peeling, etc., to ensure the use of safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

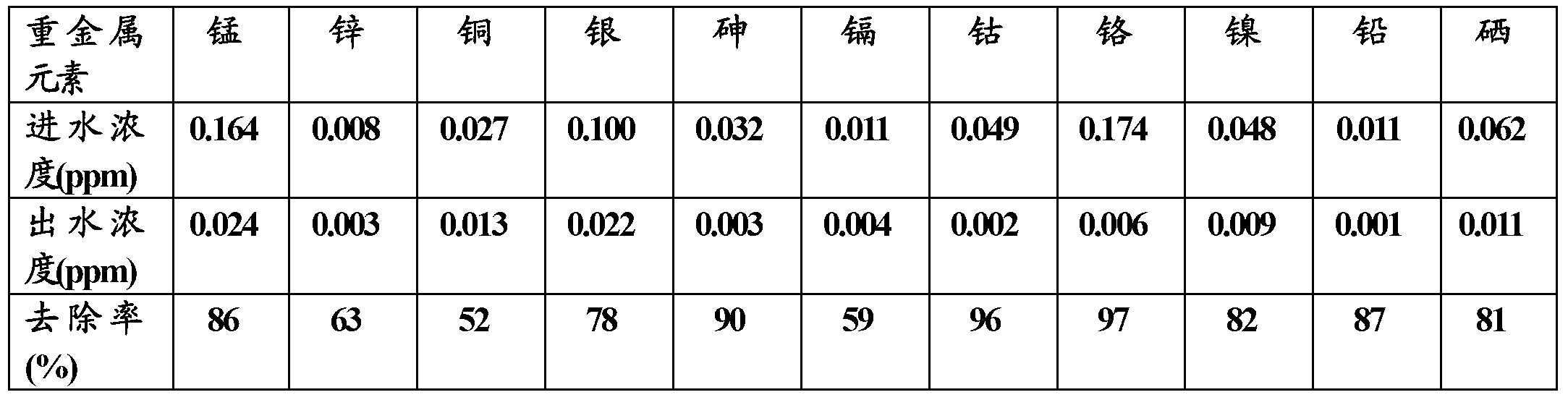

Examples

Embodiment 1

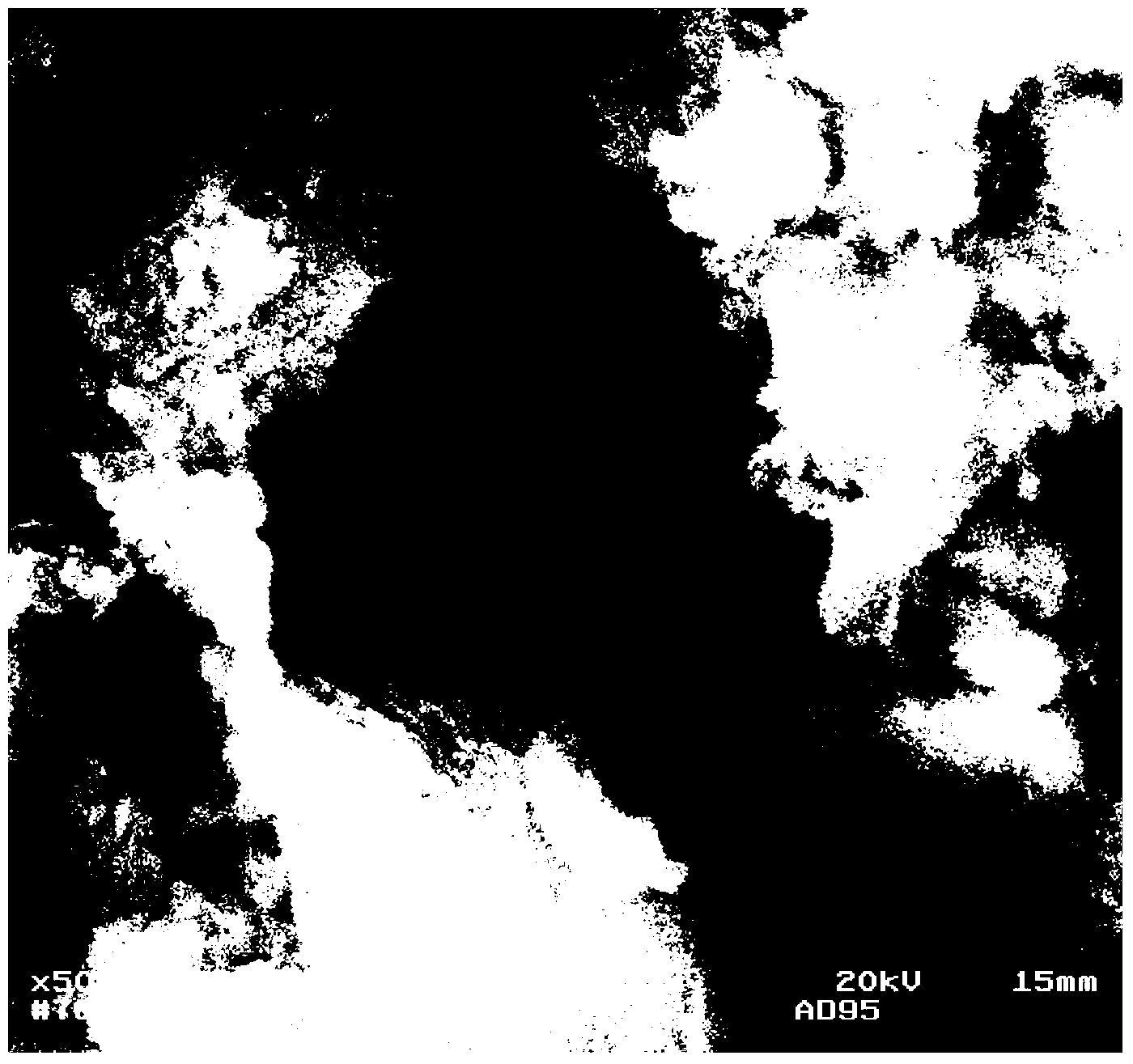

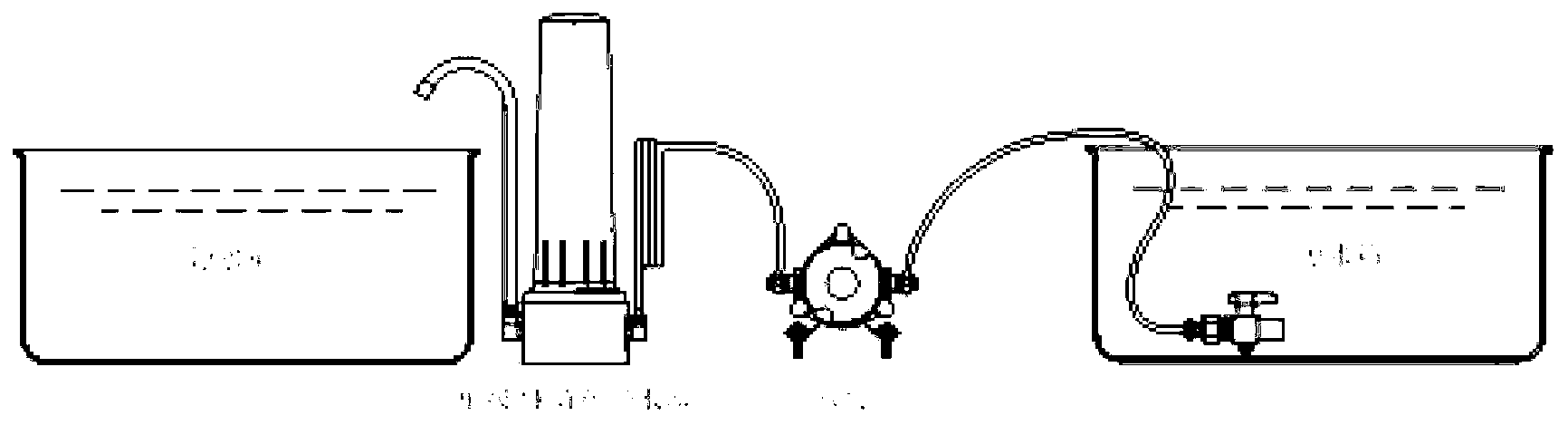

[0051] The present embodiment provides a filter material for wastewater treatment, the preparation method of which is as follows:

[0052] Step 1: prepare a soluble starch solution at room temperature, add an aqueous solution of ferrous sulfate, adjust the pH to 7.5-8.0 with sodium citrate, and obtain an aqueous solution with a starch content of 5% and a ferrous ion content of 4%;

[0053] The second step: soak the porous ceramic substrate completely in the solution prepared in the first step to make it completely wet, and take it out for more than 15 minutes and dry it for later use;

[0054] Step 3: Prepare 4wt% sodium borohydride aqueous solution, adjust the pH to 8.5-9.5 with 0.1% tartaric acid solution, and set aside;

[0055] Step 4: Quickly immerse the porous ceramic substrate dried in the second step in the sodium borohydride aqueous solution prepared in the third step. The ceramic filter element undergoes a surface chemical reaction, and takes it out for 5 minutes to ...

Embodiment 2

[0073] The present embodiment provides a filter material for wastewater treatment, the preparation method of which is as follows:

[0074] Step 1: Prepare glucose solution at room temperature, add ferrous sulfate aqueous solution, adjust pH to 7.5-8.0 with sodium citrate, and obtain an aqueous solution with 8% glucose content and 3% ferrous ion content;

[0075] The second step: soak the porous ceramic substrate completely in the solution prepared in the first step to make it completely wet, and take it out for more than 15 minutes and dry it for later use;

[0076] The third step: prepare 3.5wt% sodium borohydride aqueous solution, adjust the pH to 8.5-9.5 with 0.1% tartaric acid solution, and set aside;

[0077] Step 4: Quickly soak the porous ceramic substrate dried in the second step in the sodium borohydride aqueous solution prepared in the third step, the ceramic filter element undergoes a surface chemical reaction, and takes it out for 5 minutes to dry.

[0078] Step 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com