Filter material for adsorption of heavy metal, and preparation method and application thereof

A technology for adsorbing heavy metals and filter materials, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes. It can solve problems such as poor adsorption of heavy metals, inability to remove arsenic and heavy metals, and inability to meet arsenic filtration requirements. Achieve the effect of high adsorption and fixation function, low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

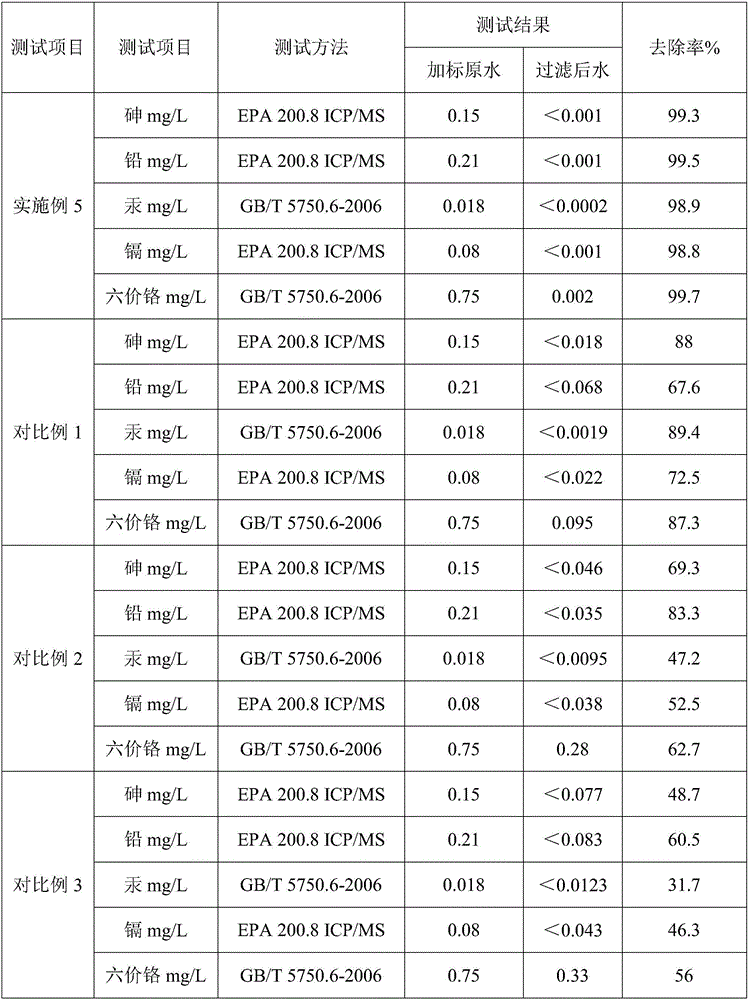

Examples

Embodiment 1

[0016] In the embodiment of the present invention, a filter material for adsorbing heavy metals is composed of the following raw materials in parts by weight: 38 parts of illite, 11 parts of tetrahydrofurfuryl alcohol, 3 parts of barium acetate, and 15 parts of polyethylene resin.

[0017] Mix tetrahydrofurfuryl alcohol with 9.8 times its mass of water to prepare a tetrahydrofurfuryl alcohol solution; mix barium acetate with 3.8 times its mass of deionized water to prepare a barium acetate solution. Mix and grind illite and polyethylene resin, pass through a 100-mesh sieve, then add tetrahydrofurfuryl alcohol solution, heat and stir at 83°C for 65 minutes, then lower the temperature to 70°C, add barium acetate solution dropwise while stirring, and then heat up Ultrasonic treatment at 128° C. for 30 minutes with an ultrasonic power of 600 W, then stirring at 100° C. until dry, and then calcining at 330° C. for 3.8 hours to obtain the filter material.

Embodiment 2

[0019] In the embodiment of the present invention, a filter material for adsorbing heavy metals is composed of the following raw materials in parts by weight: 46 parts of illite, 19 parts of tetrahydrofurfuryl alcohol, 7 parts of barium acetate, and 23 parts of polyethylene resin.

[0020] Mix tetrahydrofurfuryl alcohol with 9.8 times its mass of water to prepare a tetrahydrofurfuryl alcohol solution; mix barium acetate with 3.8 times its mass of deionized water to prepare a barium acetate solution. Mix and grind illite and polyethylene resin, pass through a 100-mesh sieve, then add tetrahydrofurfuryl alcohol solution, heat and stir at 83°C for 70 minutes, then lower the temperature to 70°C, add barium acetate solution dropwise while stirring, and then heat up Ultrasonic treatment at 128° C. for 30 minutes with an ultrasonic power of 600 W, then stirring at 100° C. until dry, and then calcining at 330° C. for 3.8 hours to obtain the filter material.

Embodiment 3

[0022] In the embodiment of the present invention, a filter material for adsorbing heavy metals is composed of the following raw materials in parts by weight: 40 parts of illite, 13 parts of tetrahydrofurfuryl alcohol, 4 parts of barium acetate, and 17 parts of polyethylene resin.

[0023] Mix tetrahydrofurfuryl alcohol with 9.8 times its mass of water to prepare a tetrahydrofurfuryl alcohol solution; mix barium acetate with 3.8 times its mass of deionized water to prepare a barium acetate solution. Mix and grind illite and polyethylene resin, pass through a 100-mesh sieve, then add tetrahydrofurfuryl alcohol solution, heat and stir at 83°C for 68 minutes, then lower the temperature to 70°C, add barium acetate solution dropwise while stirring, and then heat up Ultrasonic treatment at 128° C. for 30 minutes with an ultrasonic power of 600 W, then stirring at 100° C. until dry, and then calcining at 330° C. for 3.8 hours to obtain the filter material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com