Arsenic removal filter material, preparation method of arsenic removal filter material and application of arsenic removal filter material in drinking water purification

A filter material, porous ceramic technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of reduced adsorption capacity, coating peeling, inability to fix heavy metals, etc., to ensure the effect of safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

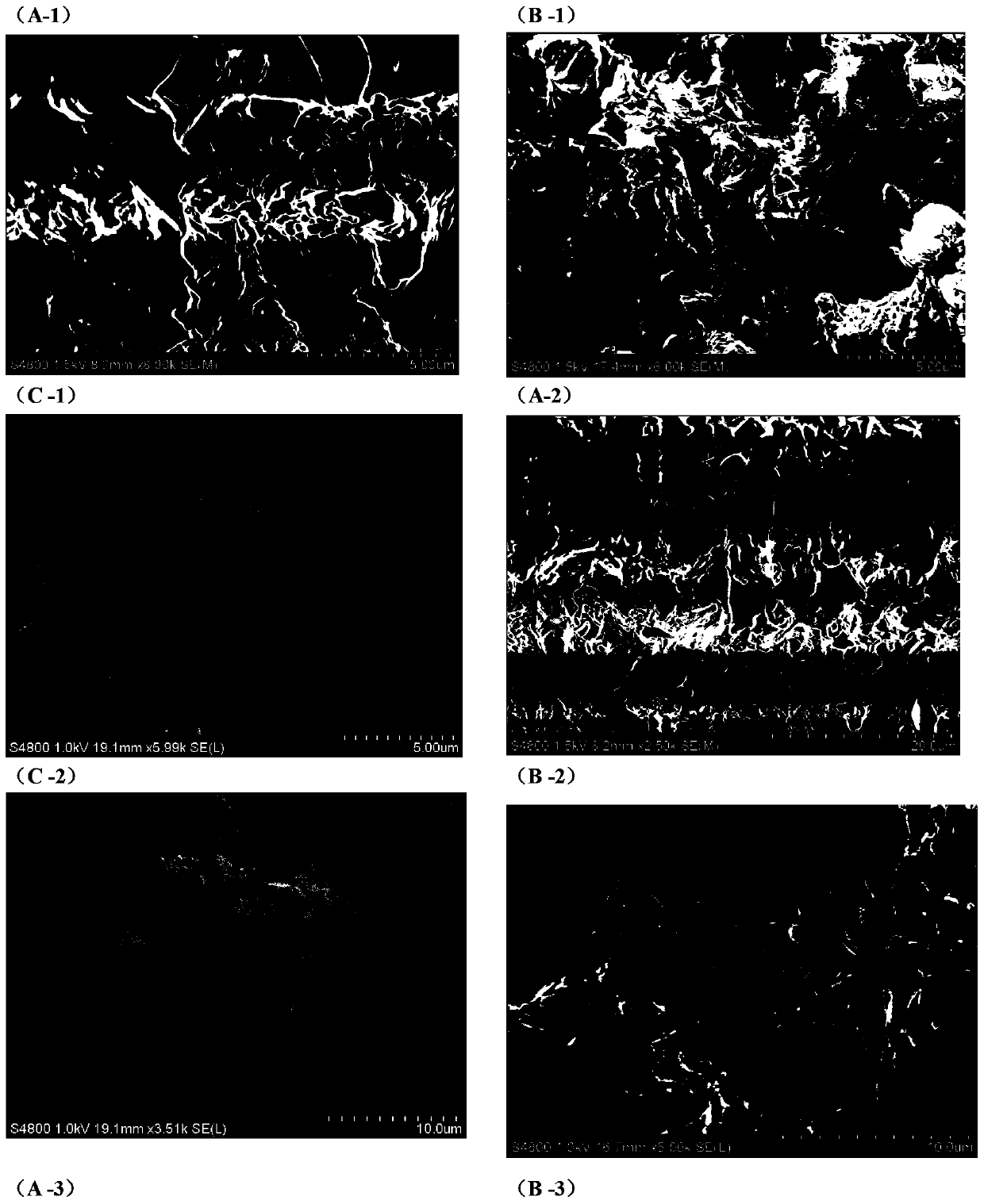

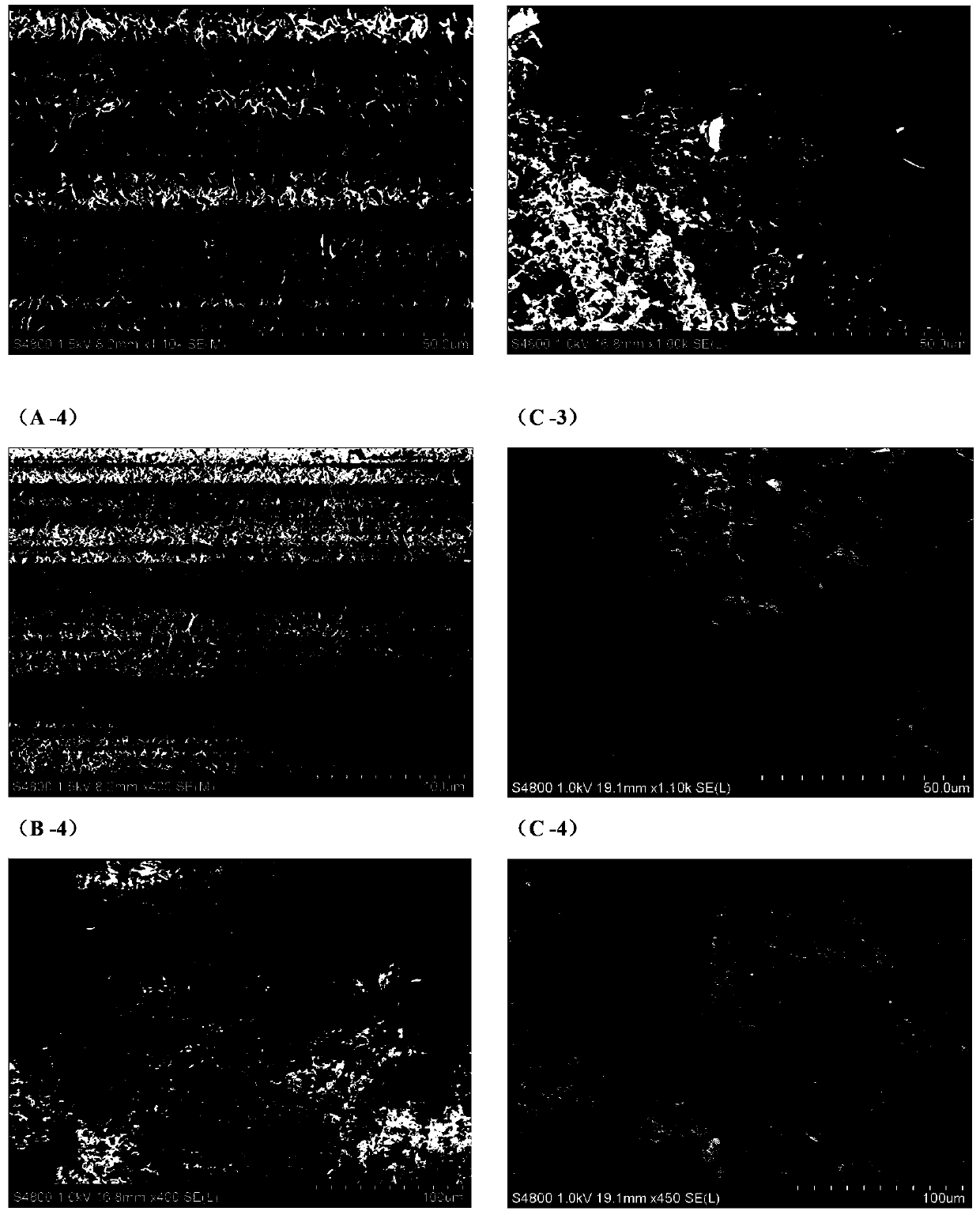

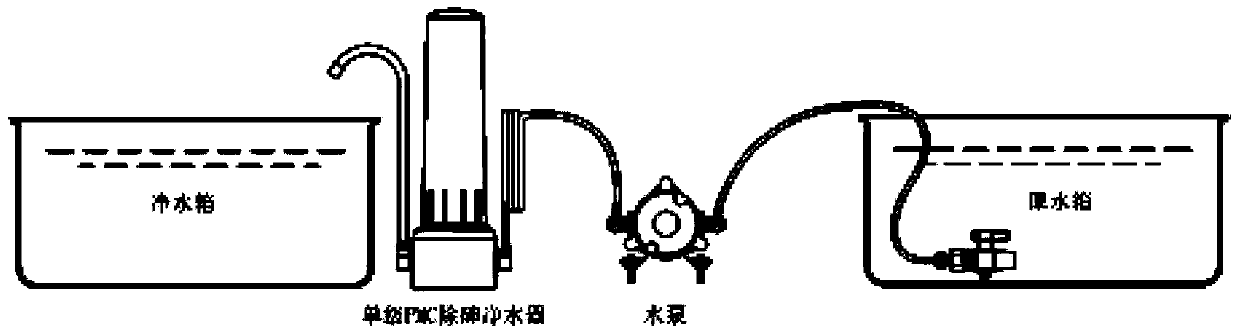

[0035] It is known that ordinary porous ceramic filter elements, such as ordinary white diatomite ceramic filter elements, can physically filter bacteria because of their well-developed micropores and good permeability. But it cannot filter heavy metal ions. Although the existing method of forming a coating on the ceramic surface can enable the ceramic to absorb arsenic and heavy metal ions, it has the problems of easy peeling off of the coating, generation of harmful waste, and unsatisfactory adsorption effect. The inventive idea of the present invention is mainly to provide a method for generating nano-iron particles in situ inside the porous ceramic filter element. The obtained filter material not only has a very high removal effect on arsenic and heavy metal ions, but also absorbs arsenic and heavy metal ions It is very stable and does not fall off. At the same time, the filter material does not have the problem of coating falling off. At the same time, the invention al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com